Construction technology of formwork support system of high-altitude cable-stayed steel operating platform

An operation platform and formwork support technology, which is applied in the field preparation and construction of pillars and building components, can solve the problems of shortening the construction period and reducing safety risks, and achieve the effects of shortening the construction period, reducing safety risks and facilitating quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

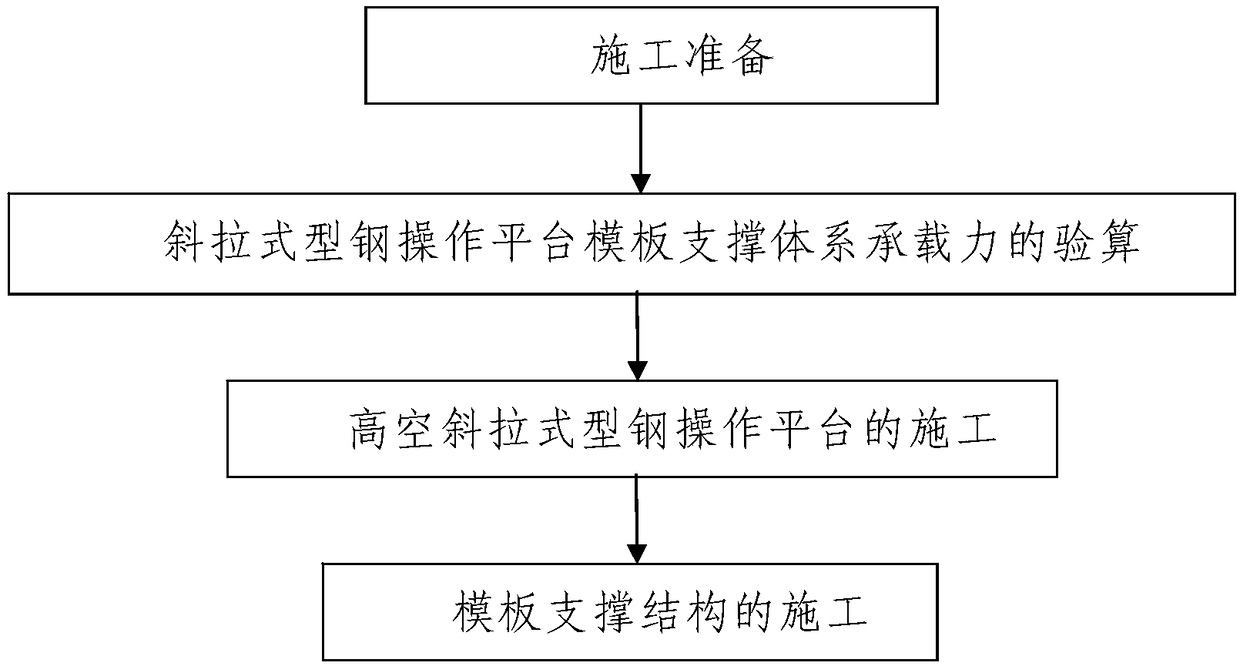

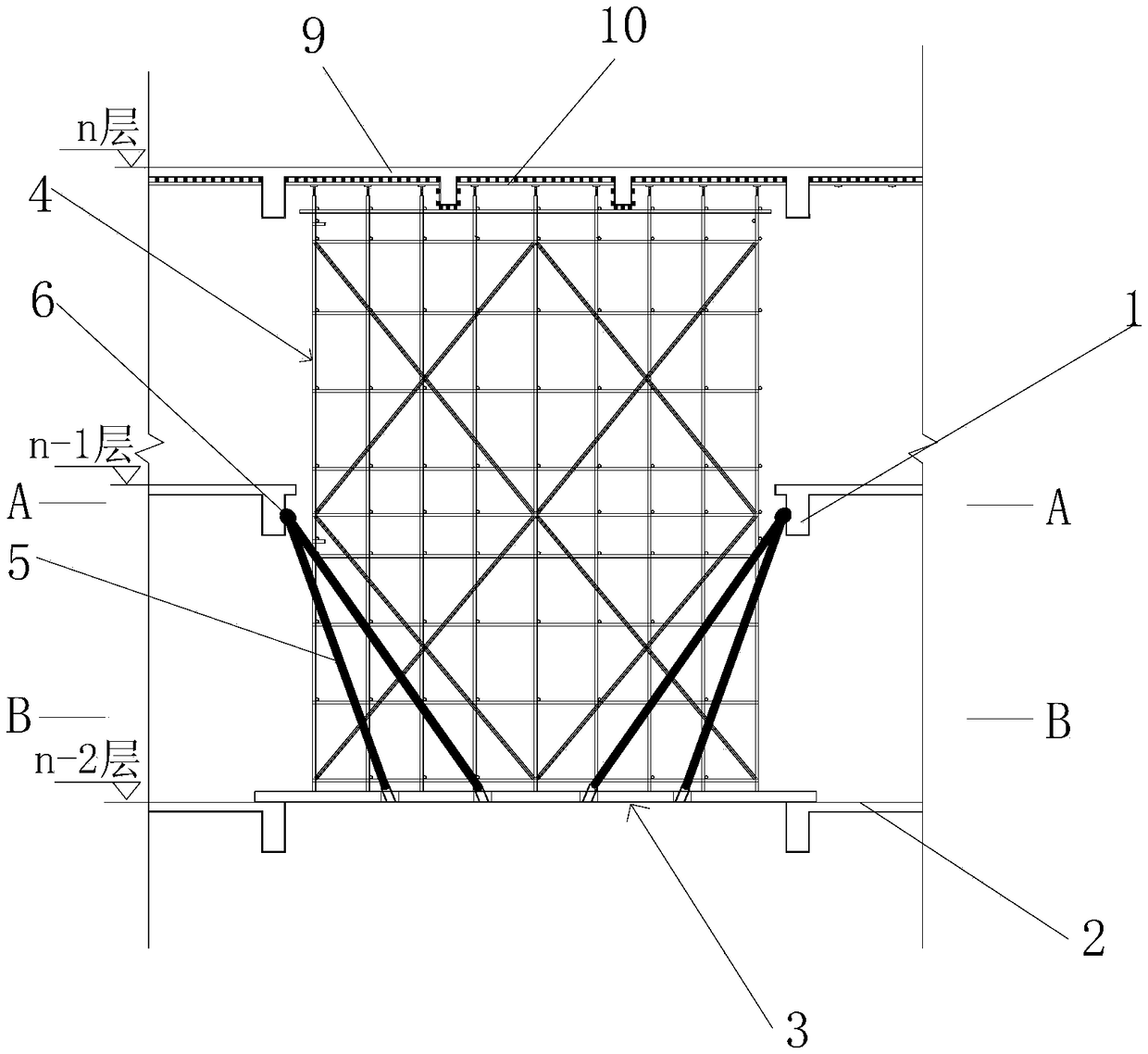

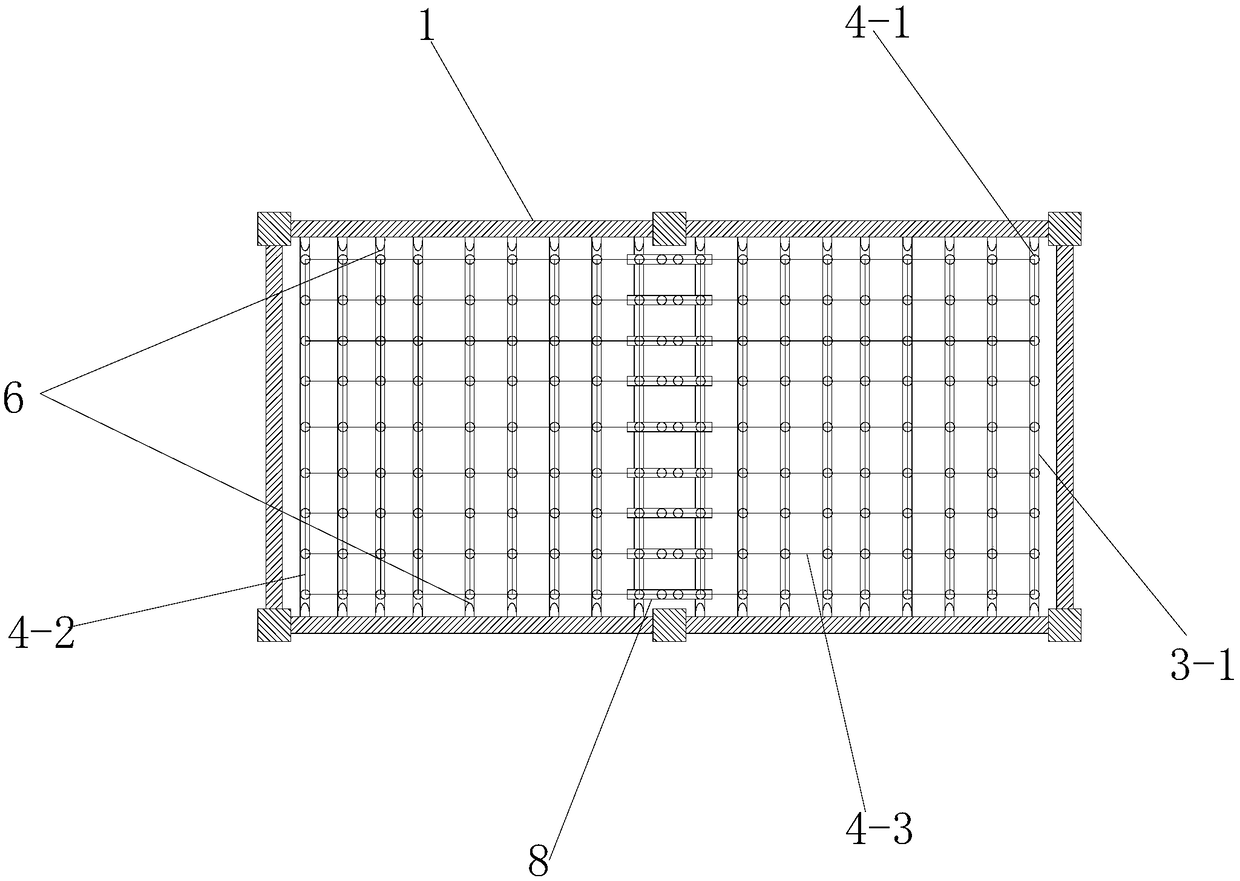

[0049] Such as figure 1 , figure 2 and 3 The construction process of a formwork support system of a high-altitude cable-stayed section steel operation platform is shown. The high-altitude cable-stayed section steel operation platform formwork support system includes a horizontally arranged section steel operation platform and a formwork support structure arranged above the section steel operation platform. The shaped steel operating platform is fixed on the structural plate 2 of the main structure, the main structure is a multi-layer hollow ring structure, and the high-altitude cable-stayed shaped steel operating platform formwork support system is used to support the nth layer of the hollow ring structure The roof 9 and the formwork 10 used to form the concrete of the roof 9, wherein n is a positive integer and n≥4; when constructing the formwork support system of the high-altitude cable-stayed steel operating platform, the process is as follows:

[0050] Step 1, construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com