Water absorption silencer

A muffler and water absorption technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve problems such as unsatisfactory muffler effect, large noise irregularities, and difficulty in absorbing low-frequency noise, and achieve superior muffler effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

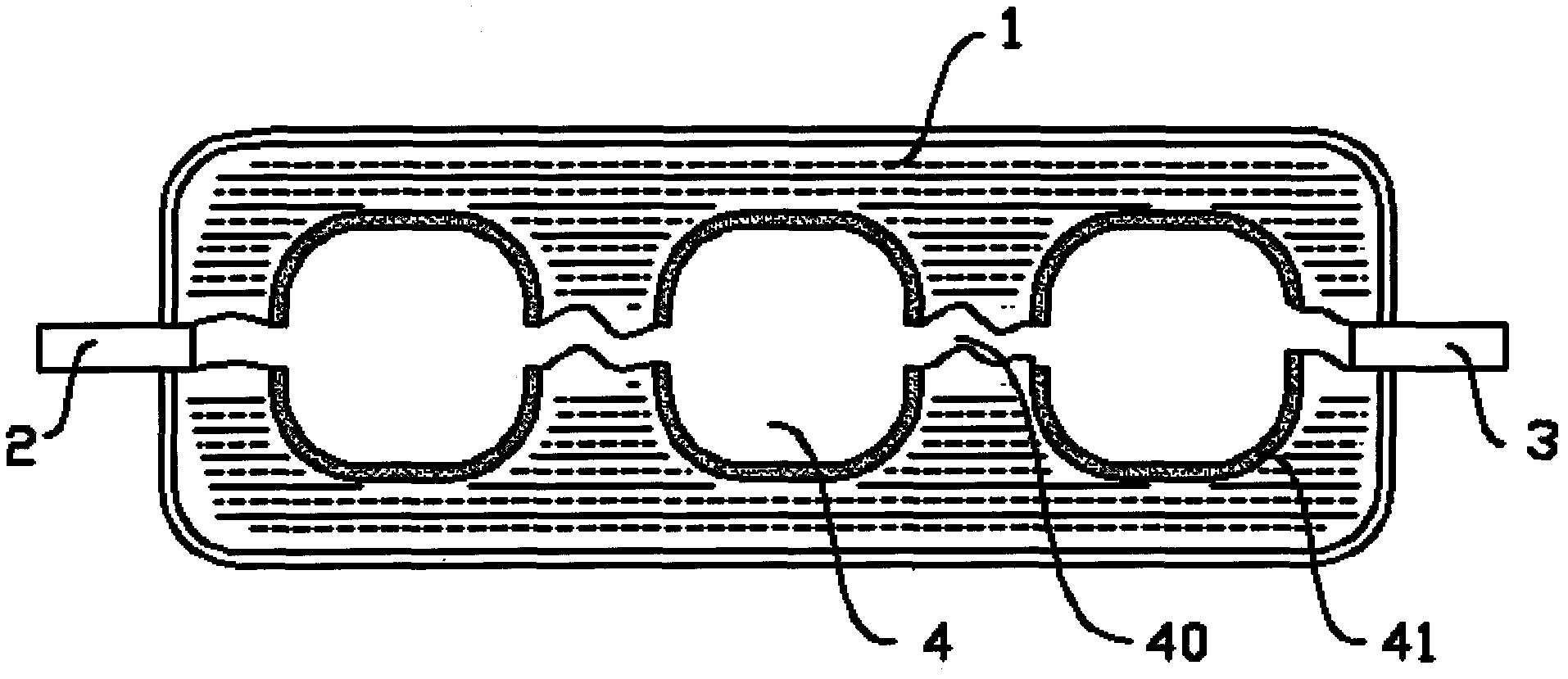

[0019] exist figure 1 In the shown embodiment, the water absorption muffler includes an outer cavity 1, a sound-absorbing floating cavity 4, an air intake pipe 2, and an exhaust pipe 3;

[0020] The air inlet pipe 2 and the exhaust pipe 3 are arranged on both sides of the outer cavity 1, and there are three sound-absorbing floating chambers 4, the inner surface of which is covered with sound-absorbing cotton 41, and the passage between each of the sound-absorbing floating chambers 4 The high temperature resistant rubber hose 40 is connected in series with the intake pipe 2 and the exhaust pipe 3;

[0021] Water is filled between the sound-absorbing floating chamber 4 and the outer chamber 1;

[0022] In the above-mentioned water-absorbing muffler, the muffler floating chamber 4 is made of high-temperature-resistant plastic;

[0023] In the above-mentioned water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com