Low-noise pneumatic tire

A pneumatic tire, low-noise technology, applied in tire parts, vehicle parts, transportation and packaging, etc., can solve the problems affecting automobile fuel consumption and walking stability, reducing tire heat dissipation, and a single value of resonance frequency. The effect of improving fuel consumption and running stability, reducing cavity resonance noise, and reducing noise energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

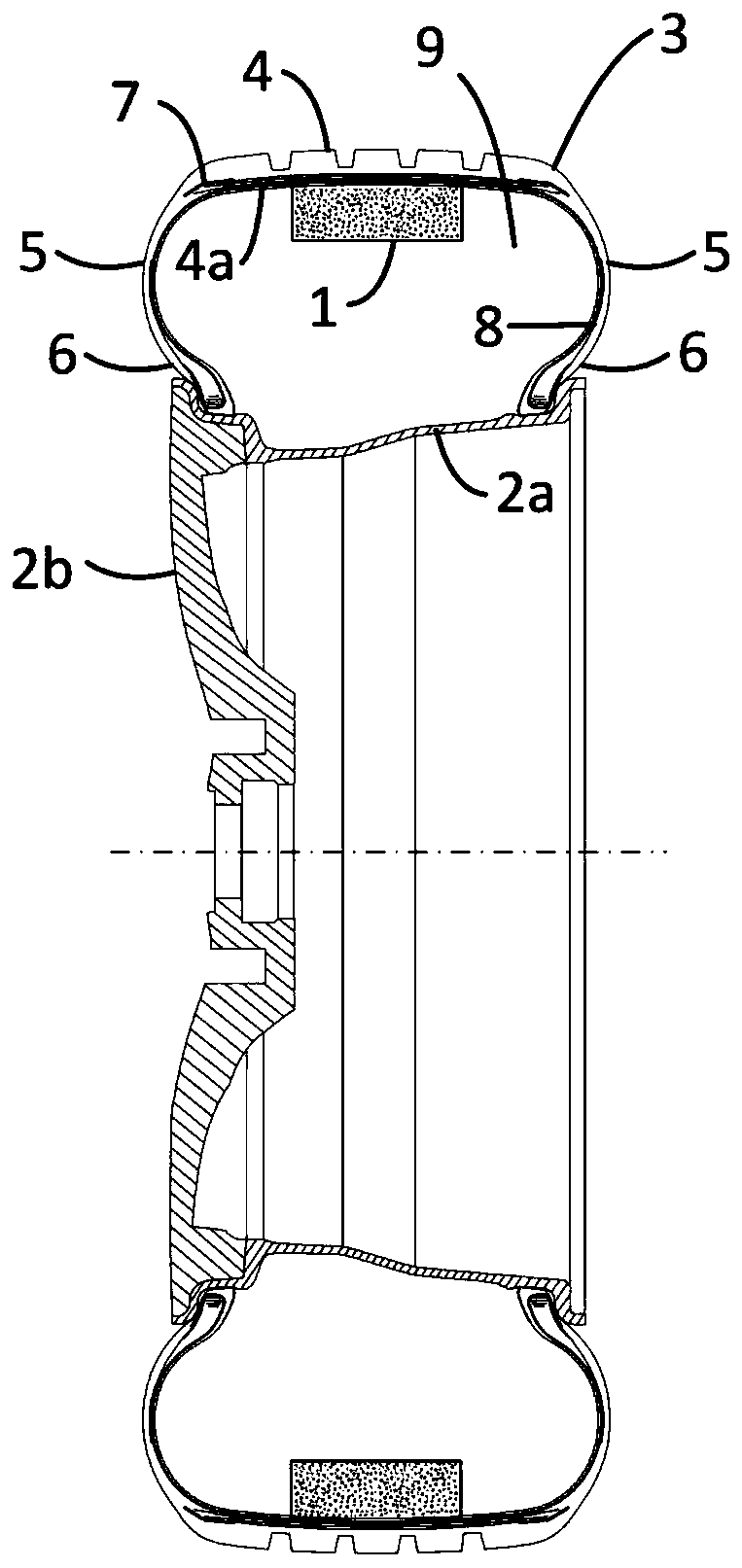

[0031] see figure 1 , the low-noise pneumatic tire in this embodiment refers to the pneumatic tire 3 formed with the tire cavity 9 jointly by the tread inner surface 4a of the tire and the rim 2a; the pneumatic tire 3 is mounted on the rim 2a and supported by the spokes 2b; The tire 3 includes: a tread portion 4, bead portions 6 on the left and right sides, sidewall portions 5 on the left and right sides connecting the tread portion 4 and the bead portion 6, and between the left and right bead portions 6 A carcass 7 extends inside the tire, a belt 8 is provided on the outer peripheral side of the carcass of the tread portion 4, and the pneumatic tire 3 is attached to a wheel so that the cavity of the pneumatic tire 3 is sealed by the rim 2a.

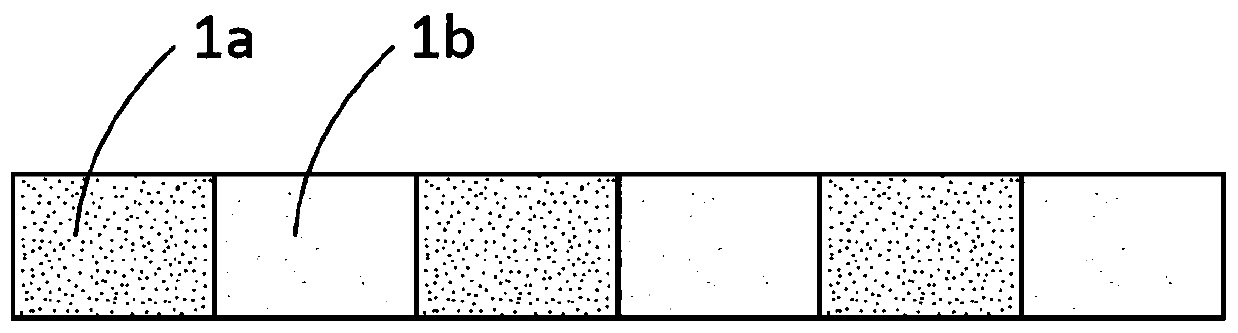

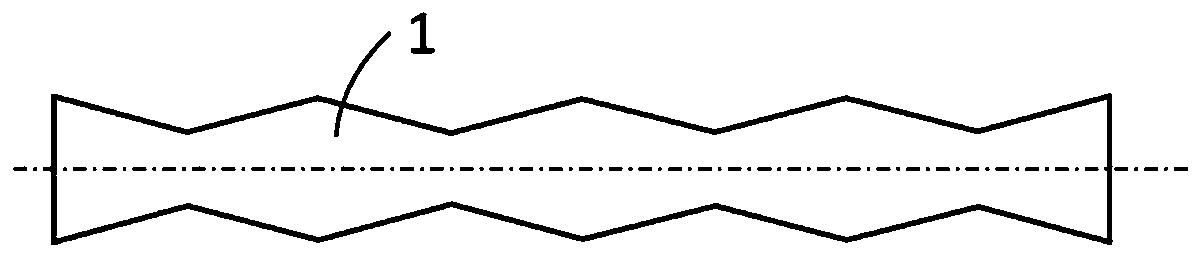

[0032] Such as figure 1 As shown, the low-noise pneumatic tire in this embodiment has a noise absorber 1 installed in the tire cavity 9, the noise absorber 1 is arranged in the tire cavity 9 along the tire circumferential direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com