Minus 48V direct current frequency-conversion speed-regulation temperature control system

A temperature control system, DC frequency conversion technology, applied in heating and ventilation control systems, heating and ventilation safety systems, household heating, etc., can solve the temperature rise of the temperature control cabinet, battery swelling, affecting the service life of the compressor, etc. problem, to achieve the effect of prolonging the service life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments.

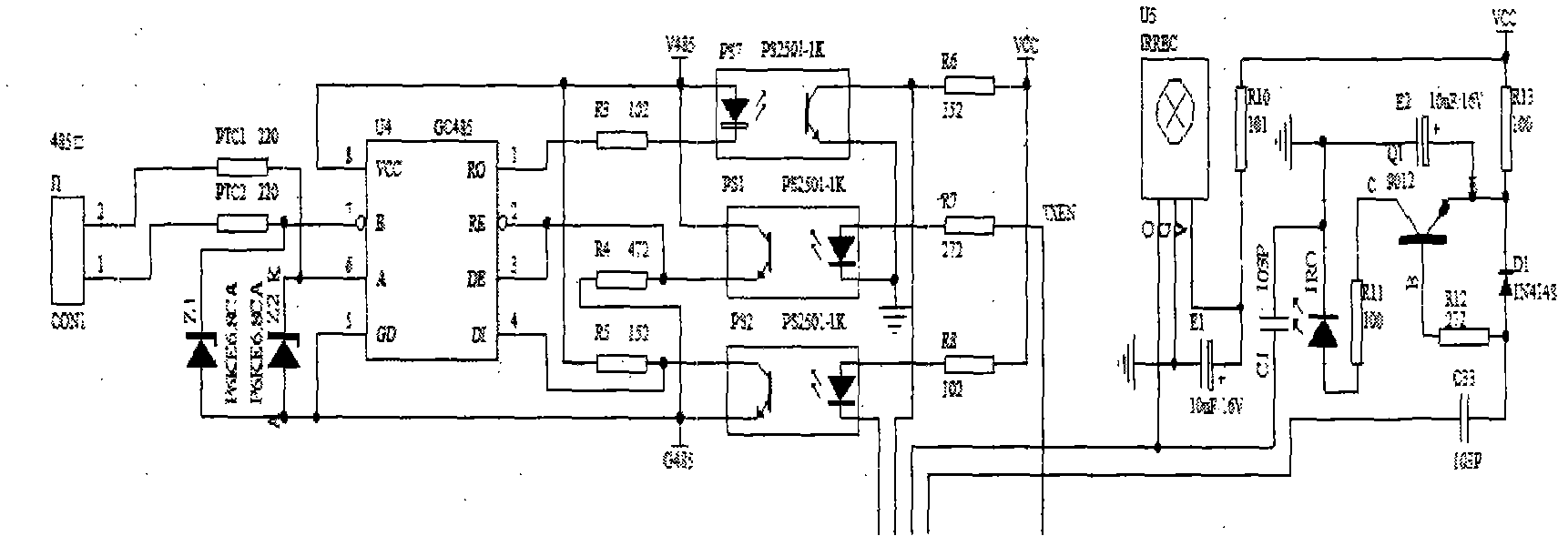

[0022] figure 1 It is the communication unit between the control system and the external or monitoring center, and J1 is the RS485 communication output. The overall isolation circuit is completely isolated from the power system of the target unit, which can achieve high anti-interference and high stability.

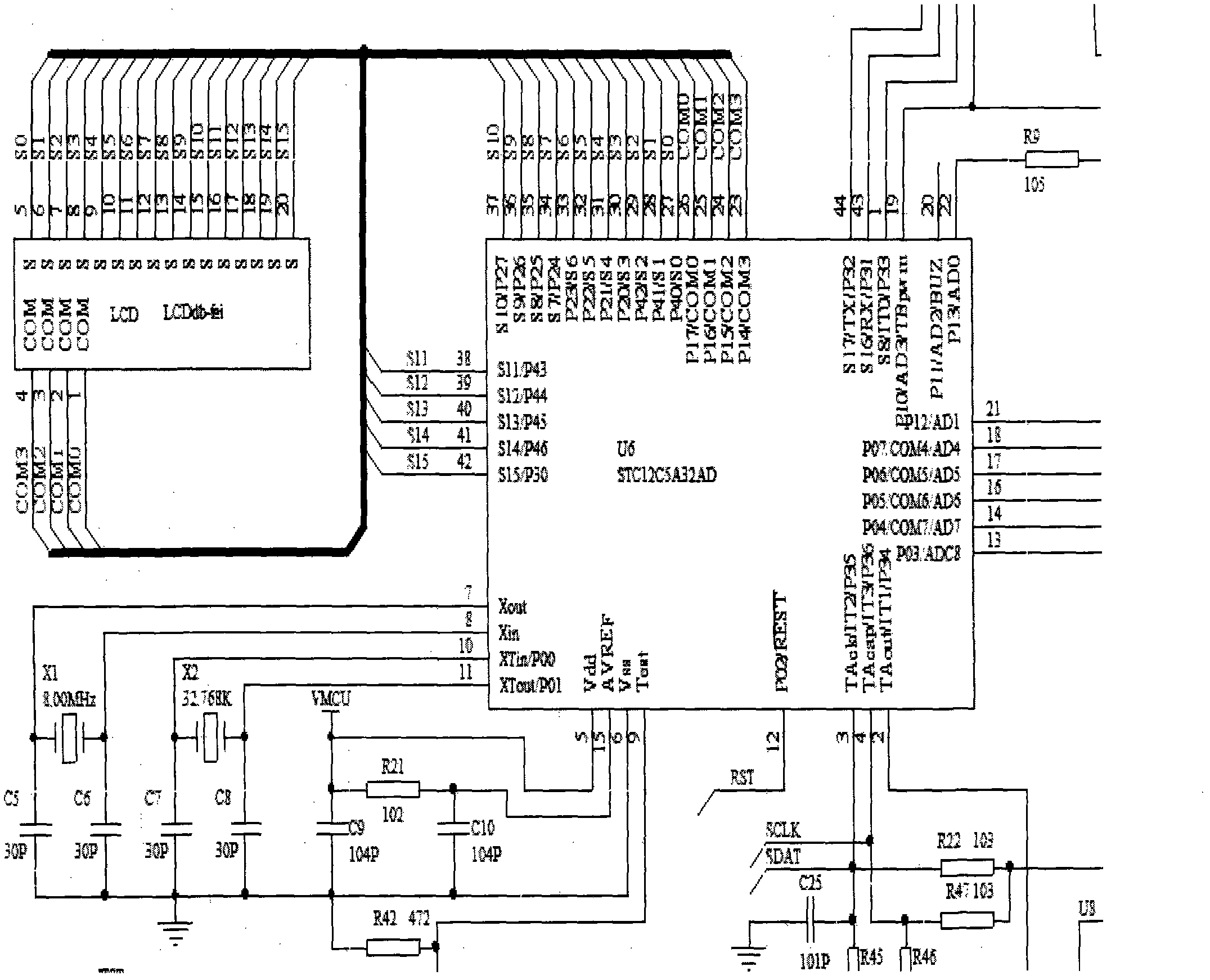

[0023] figure 2 It is the main control CPU and LCD display unit, and is the control core and command output center of the whole machine. Liquid crystal LCD displays real-time data, including target unit temperature and humidity, compressor speed and fan speed display. Can visually see the corresponding relationship between temperature and speed. And it can display the running time and power consumption statistics of the system in real time.

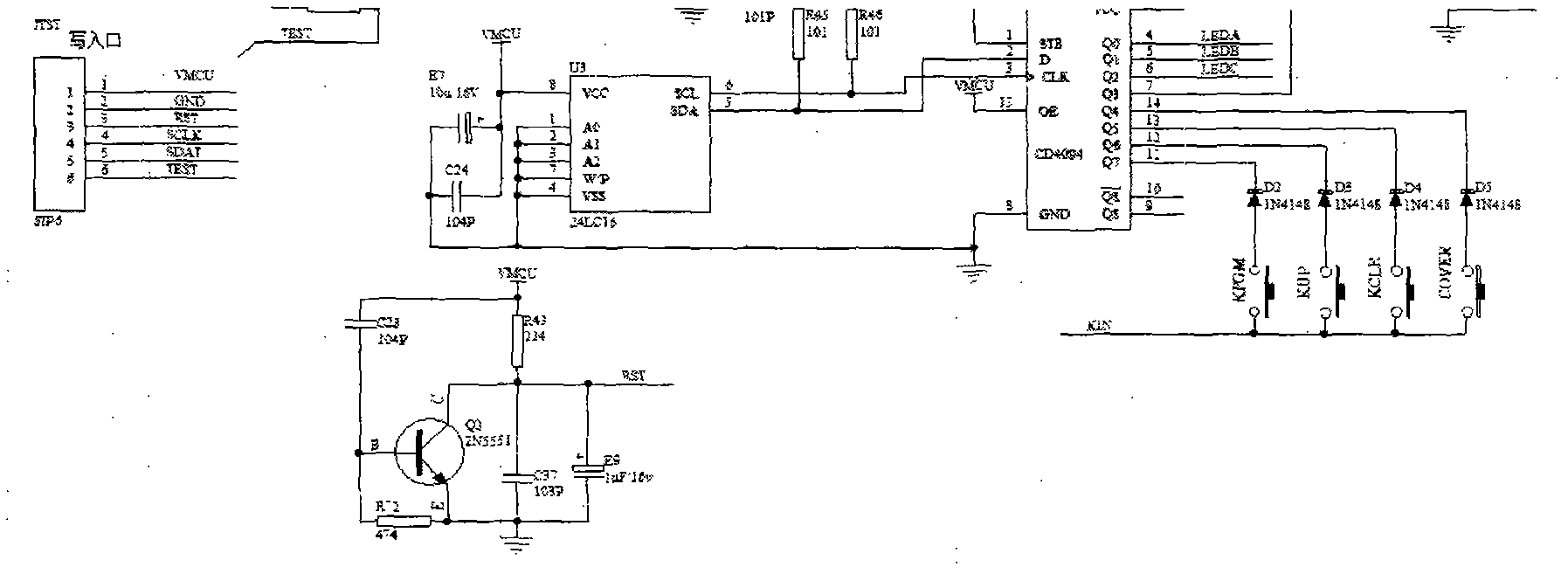

[0024] image 3 Input for online software upgrade and man-machine dialogue. Configure 4 buttons to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com