Automatic opening-clamping machine for electronic primer

An electronic detonator and bayonet technology, which is applied to weapon accessories, fuzes, offensive equipment, etc., can solve the problems of flattening of the electronic detonator shell, uneven distribution of sticking marks, uneven depth of sticking marks, etc., and achieves reasonable depth of sticking marks, Reliable safety performance and uniform distribution of card marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

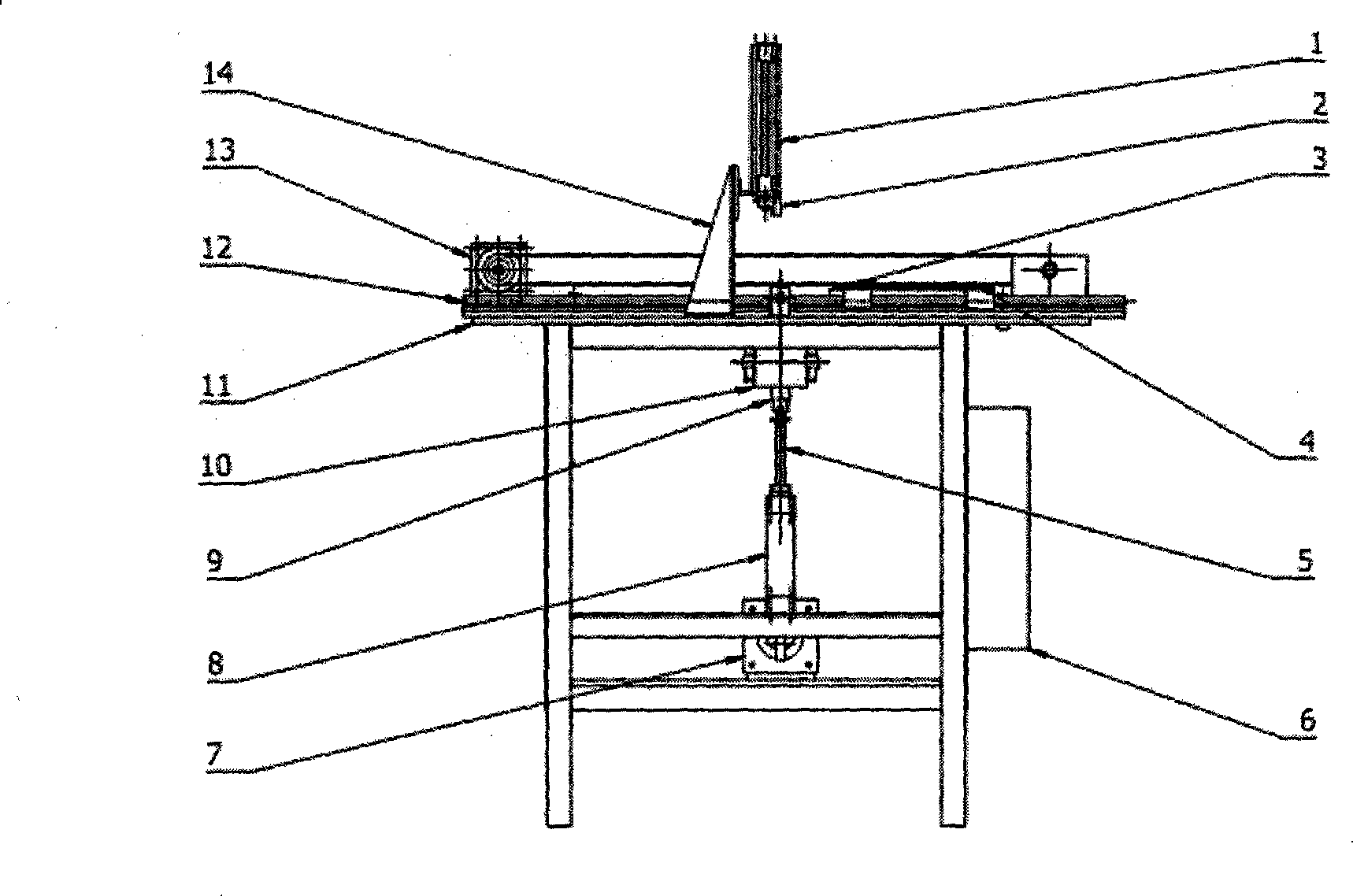

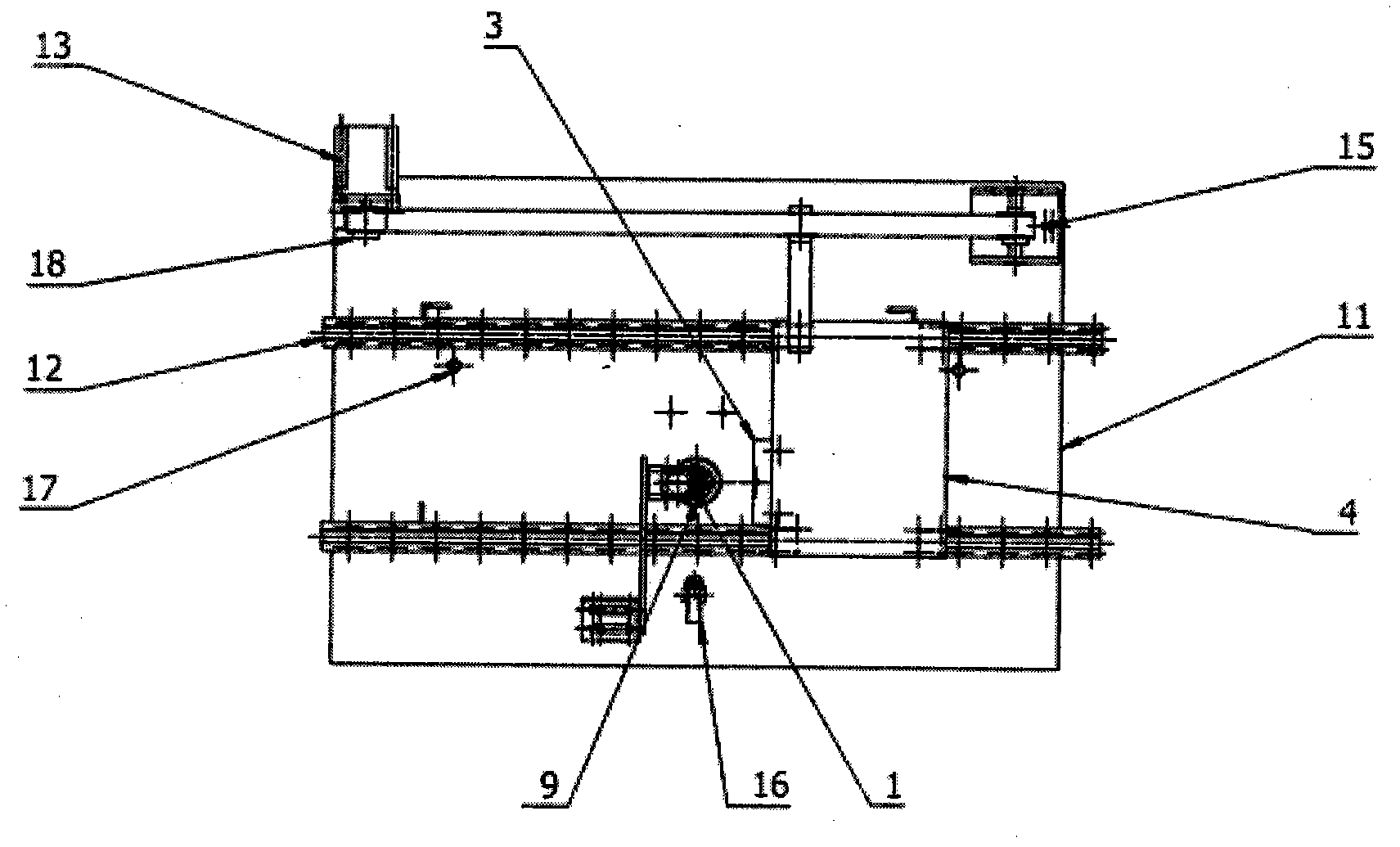

[0010] Such as figure 1 with figure 2 shown

[0011] An automatic bayonet machine for electronic detonators consists of a workbench 11, a transport mechanism, a pressing device, an upper-top linkage mechanism, a control box 6 and a bayonet extrusion forming mechanism 9.

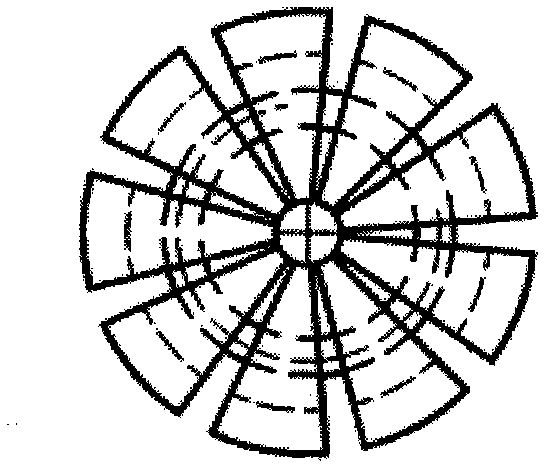

[0012] The bayonet extrusion molding mechanism 9 runs through the workbench 11 and is installed on the lower wall surface of the workbench 11. The outer wall surface of the bayonet extrusion molding mechanism 9 is conical, and the large end surface of the bayonet extrusion molding mechanism 9 is in contact with the workbench. The upper surface of 11 is located on the same horizontal plane, and the bayonet extrusion molding mechanism 9 is composed of more than three fan-shaped pressure mouth cones, which are evenly distributed in a ring shape, and each fan-shaped pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com