Special fixture for friction durability test of automobile touch screen

A technology of durability test and special fixture, which is applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of easily damaged touch screen, large clamping force of welding clamp, and single structure, so as to ensure the accuracy and stability of the experiment High, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

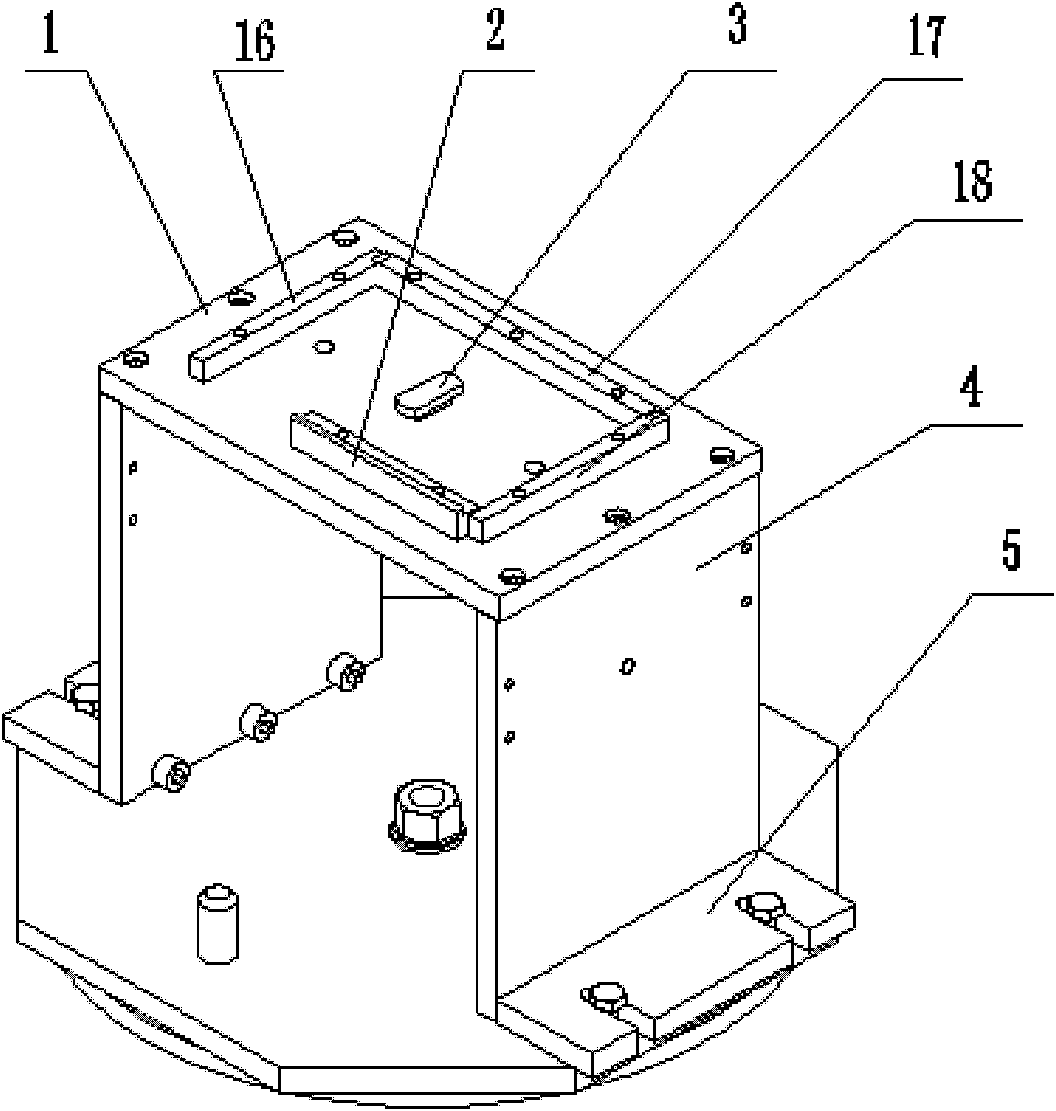

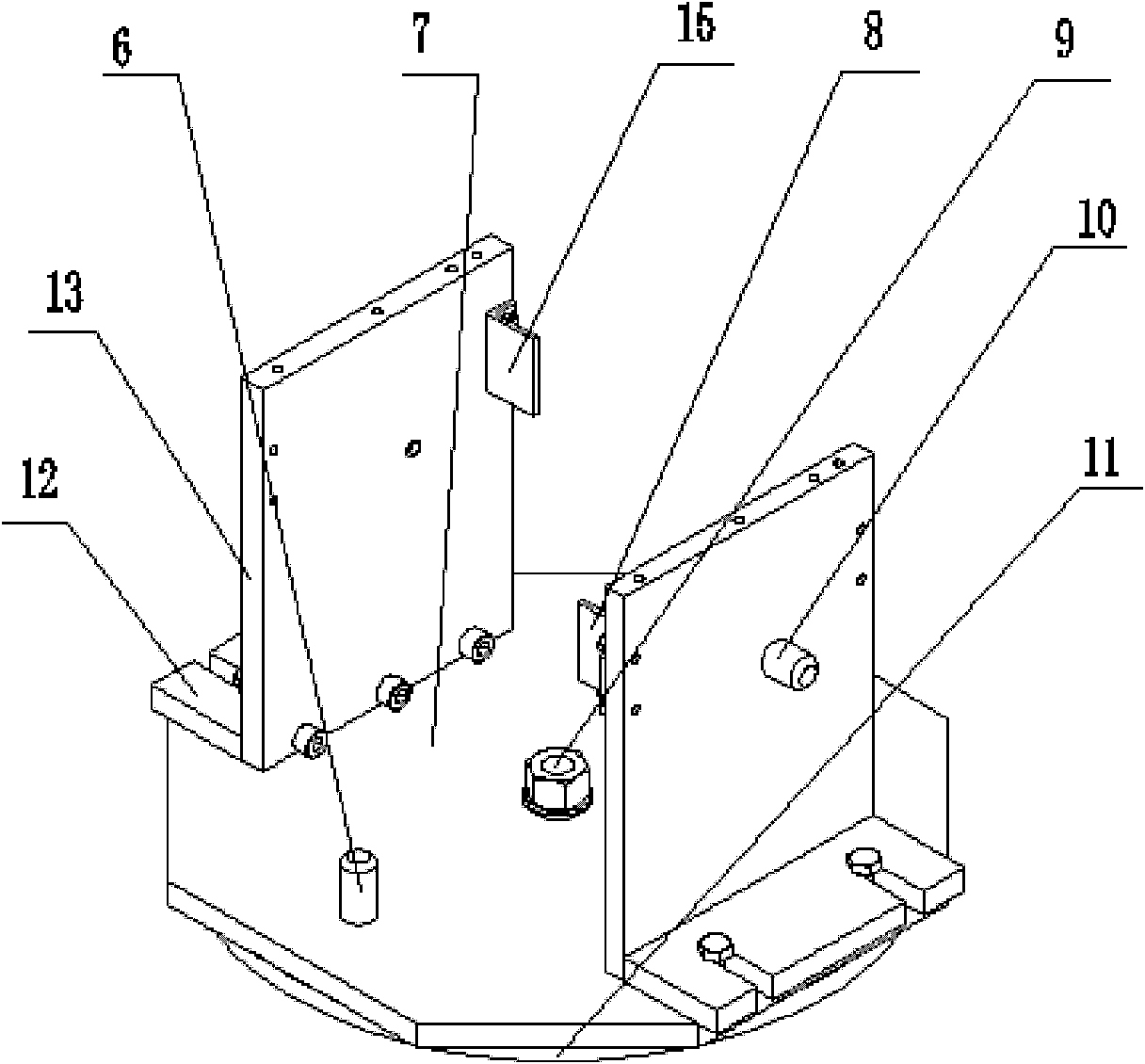

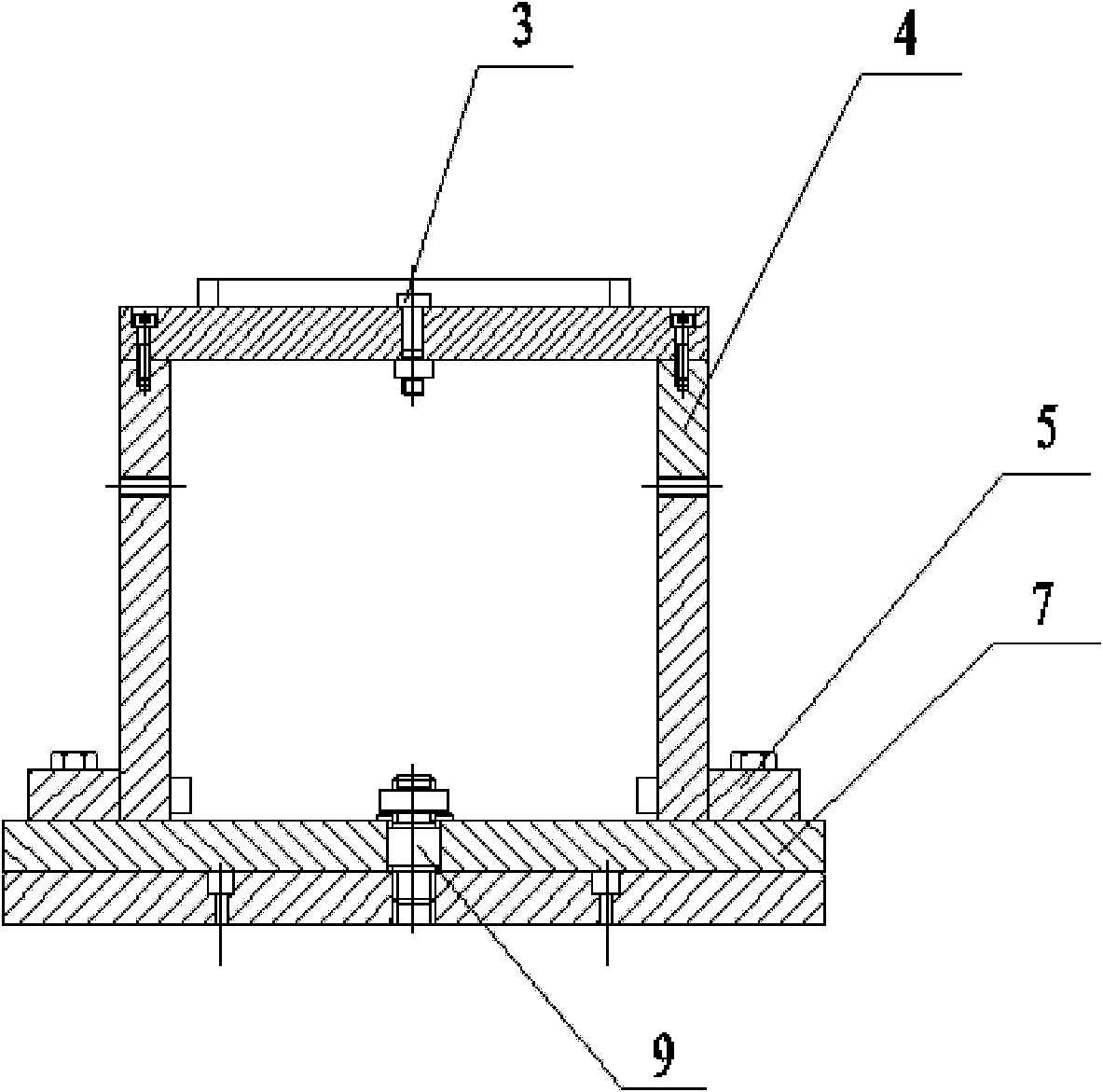

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

[0028] The special fixture for friction durability test of automobile touch screen according to the present invention is composed of positioning plate 1, No. Bottom plate 7, right fine adjustment baffle 8, rotating stud 9, right fine adjustment screw 10, rotary dial 11, left adjustment bottom plate 12, left positioning baffle 13, left fine adjustment screw 14, left fine adjustment baffle 15, No. 2 adjustment pad Plate 16, No. 3 adjustment backing plate 17 and No. 4 adjustment backing plate 18 form. Among them: right positioning baffle 4 and left positioning baffle 13, right adjusting bottom plate 5 and left adjusting bottom plate 12, right fine-tuning baffle 8 and left fine-tuning baffle 15, right fine-tuning screw 10 and left fine-tuning screw 14 and No. 2 adjusting pad Plate 16 and No. 4 adjusting backing plate 18 are parts with the same structure respectively. Each part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com