Computer equipment with automatic dust removal function

An automatic dust removal, computer technology, applied in the direction of pollution prevention methods, electrical digital data processing, cleaning methods and appliances, etc., can solve the problems affecting the circulation of hot and cold airflow of the casing, blocking the air inlet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

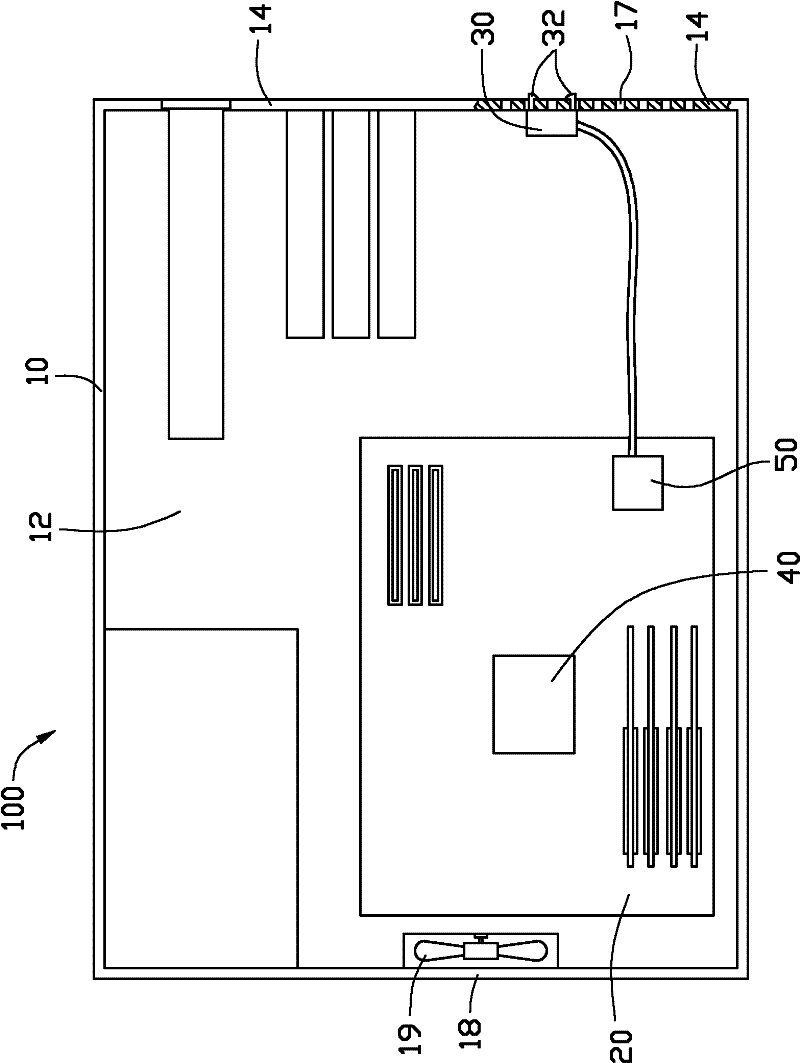

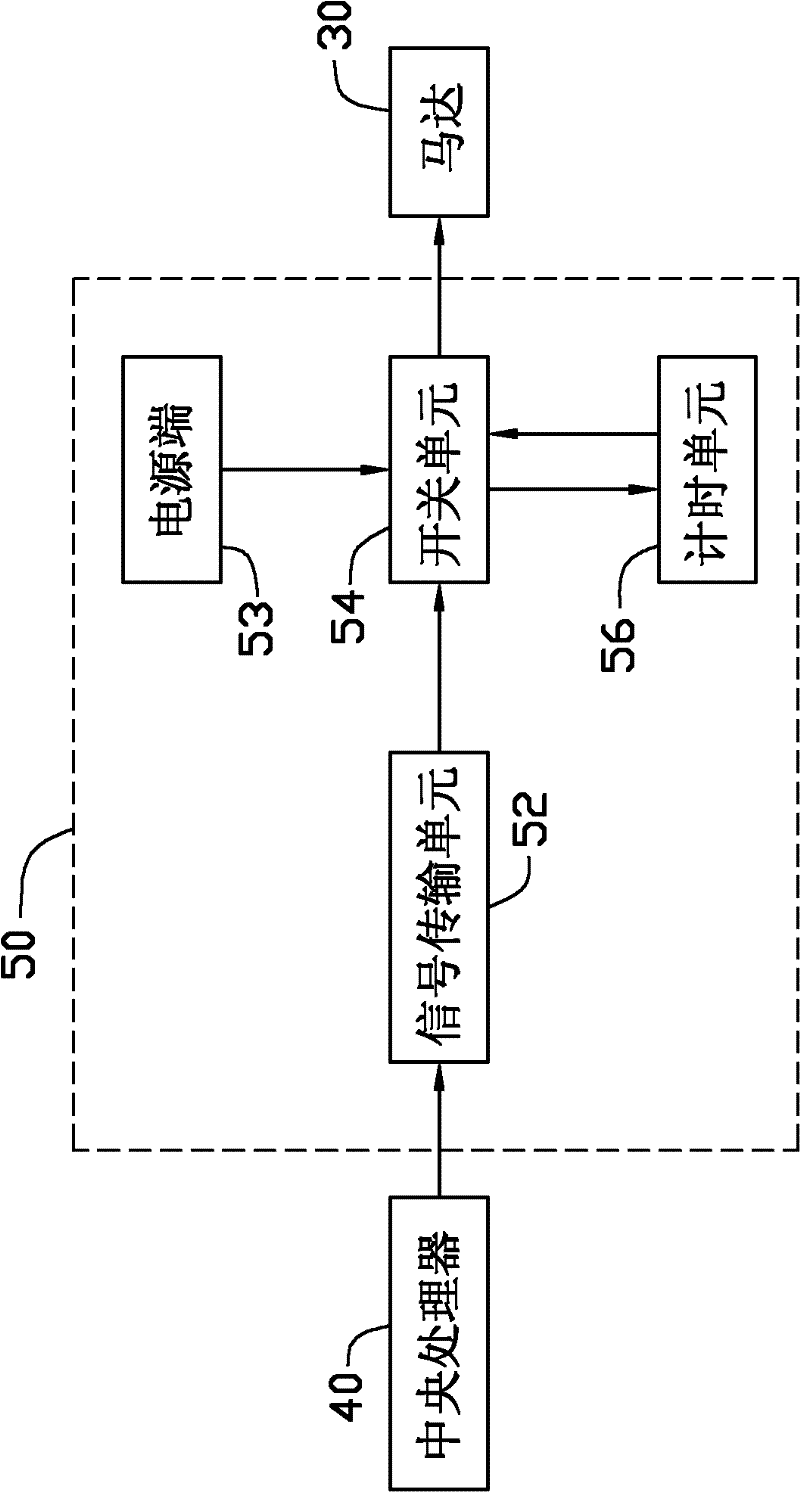

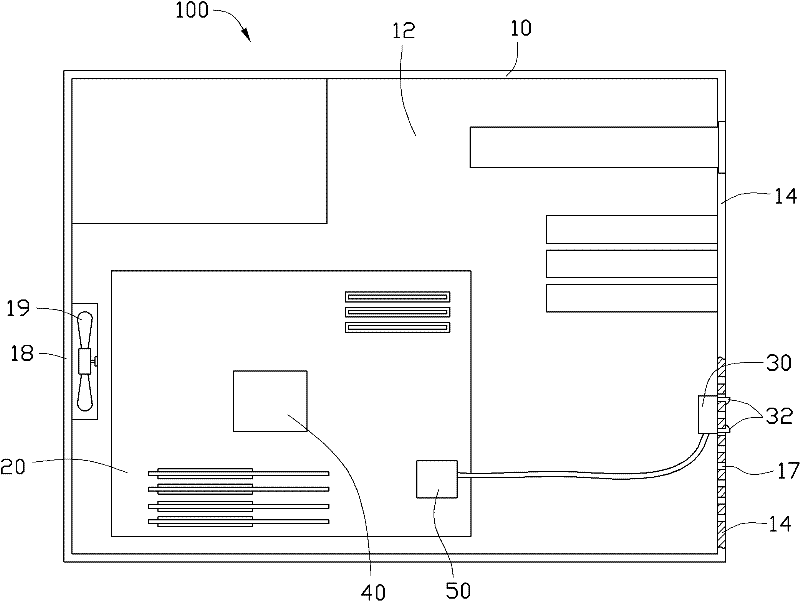

[0025] see figure 1 , the computer equipment 100 includes a casing 10, a circuit board 20 accommodated in the casing 10, and a vibrating element located on the inner wall of the casing 10. In this embodiment, the vibrating element is a vibrating motor 30 .

[0026] The casing 10 is in the shape of a hollow cuboid, and includes a rectangular first panel 12 and a side panel 14 vertically extending from a periphery of the first panel 12 . The casing 10 further includes a second panel opposite to the first panel 12 and covering the end of the side panel 14 . In order to clearly show the internal structure of the casing 10, the second panel is omitted in the figure.

[0027] An air inlet and an air outlet 18 are defined on the side panel 14 . The air outlet 18 passes through the side plate 14 , so that the internal system of the casing 10 communicates with the external environment. A fan 19 is disposed at the air outlet 18 for extracting the air in the casing 10 to the outside....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com