Structure of touch panel and manufacturing method thereof

A technology of touch panel and manufacturing method, applied in the field of touch panel structure and its manufacturing, capable of solving problems such as influence of process stability, low yield rate, low process yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

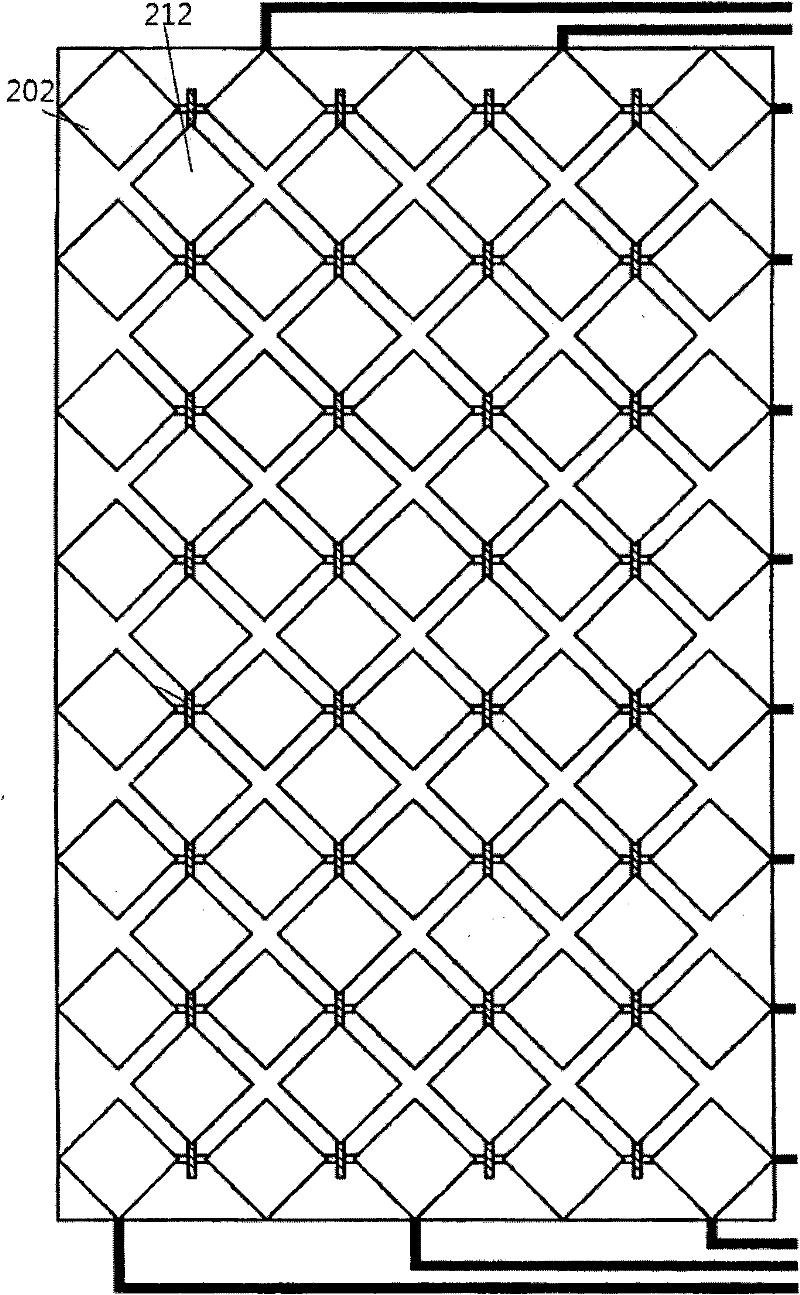

[0077] Please refer to Figure 3a to Figure 3d Shown is the structure of the touch panel provided by an embodiment of the present invention. in Figure 3b is along Figure 3a The sectional view drawn by the section line a-a' of Figure 3c is along Figure 3a The sectional view drawn by the section line b-b' of Figure 3d is along Figure 3a The cross-sectional view drawn by the section line c-c'. The touch panel of the present invention includes: a removable transparent substrate 300 and a sensing structure 30, the removable transparent substrate 300 has an upper surface 301 and an edge 303, the edge 303 is located at the periphery of the upper surface 301, and the sensing structure 30 is set on the upper surface 301 . The flexible transparent substrate 300 is made of flexible material and can be rolled into a roll shape. The material of the flexible transparent substrate 300 can be one of PEN, PET, PES, flexible glass, PMMA, PC or PI, for example, and can also be a mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com