Automatic stacker for small potato harvester

A stacker and harvester technology, which is applied to digging harvesters, harvesters, applications, etc., can solve the problems of low potato yield and low harvesting efficiency, and achieve the effect of saving labor and simple automatic stacking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

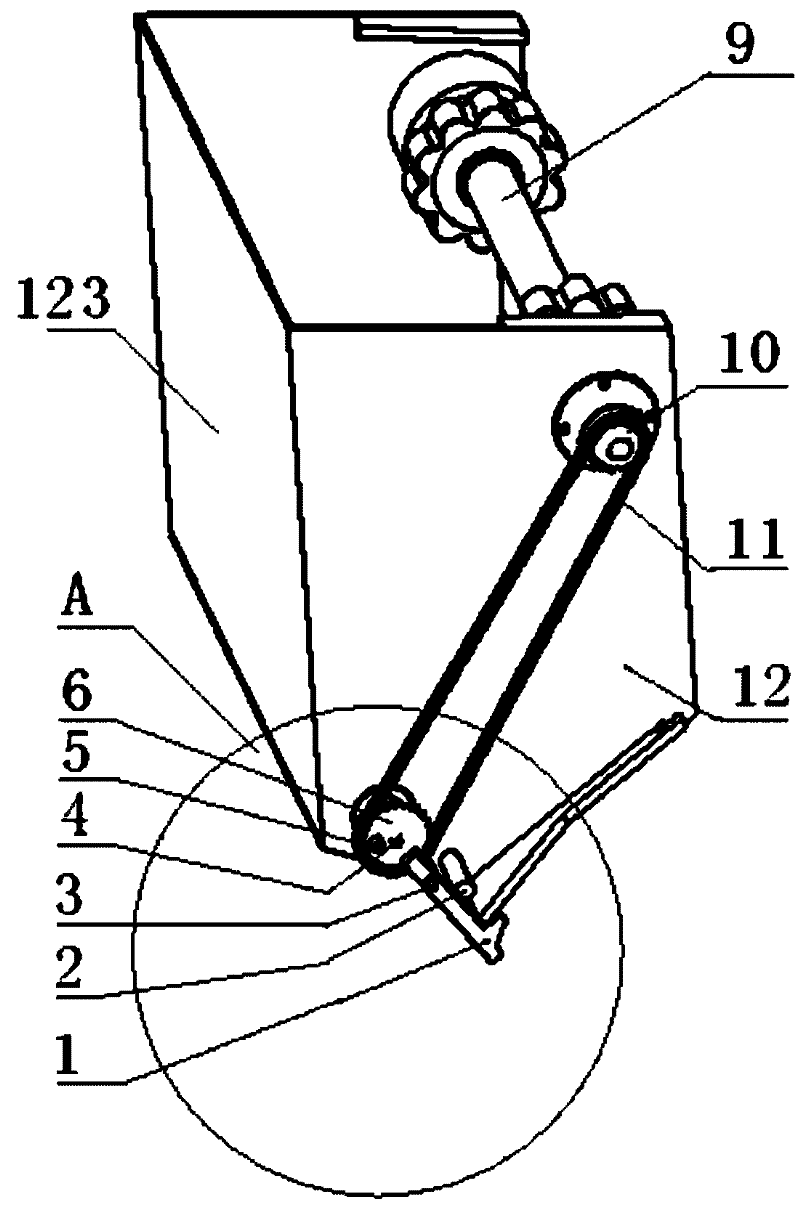

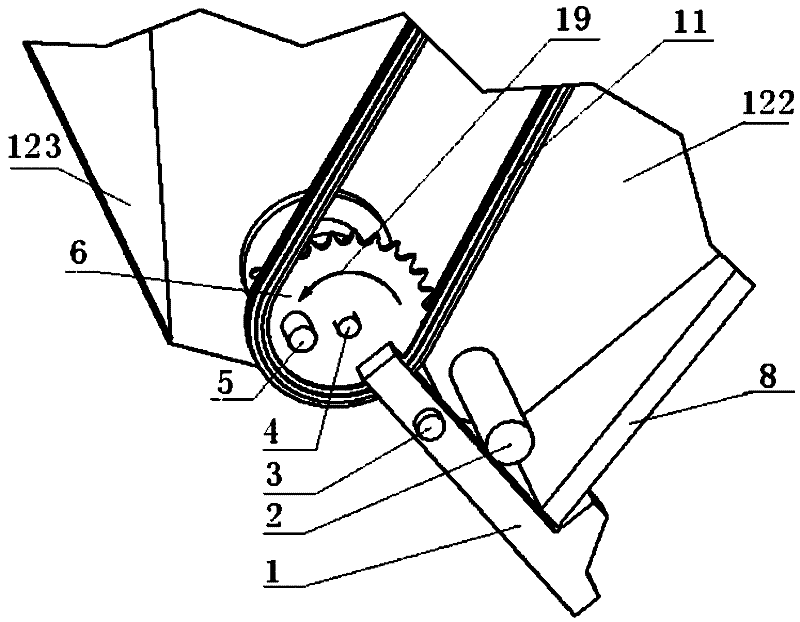

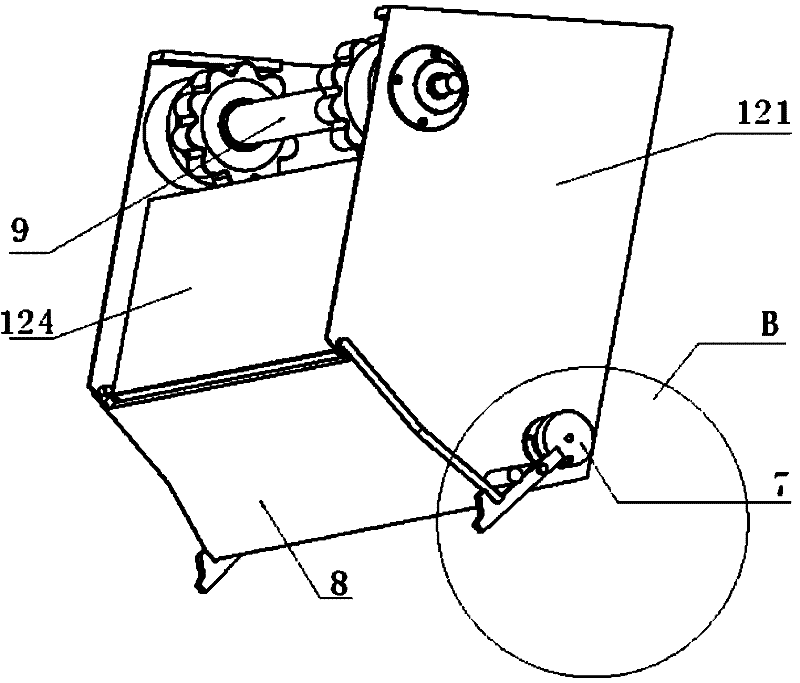

[0024] like figure 1 Schematic diagram of the right rear direction of the automatic stacker and image 3 As shown in the structural diagram of the left front direction of the automatic stacker, the automatic stacker in this embodiment consists of a bar lock hook 1, a limit post 2, a bar lock hook rotating shaft 3, a driven shaft 4, a shifting tooth 5, and a large sprocket 6. The dial 7, the lower cover of the stacker box 8, the shaking chain drive shaft 9, the small sprocket 10, the chain 11 and the stacker box 12, the shaking chain drive shaft 9 is on the upper part of the stacker box 12 It is installed on the left side wall 121 of the stacker box body and the right side wall 122 of the stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com