Detachable setup package applied to aluminum alloy template pre-buried part and method

A technology of aluminum alloy formwork and embedded parts, which is applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components, which can solve the leakage of embedded parts, Rivets fix problems such as difficulty in construction, so as to avoid leakage problems, solve construction difficulties, and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

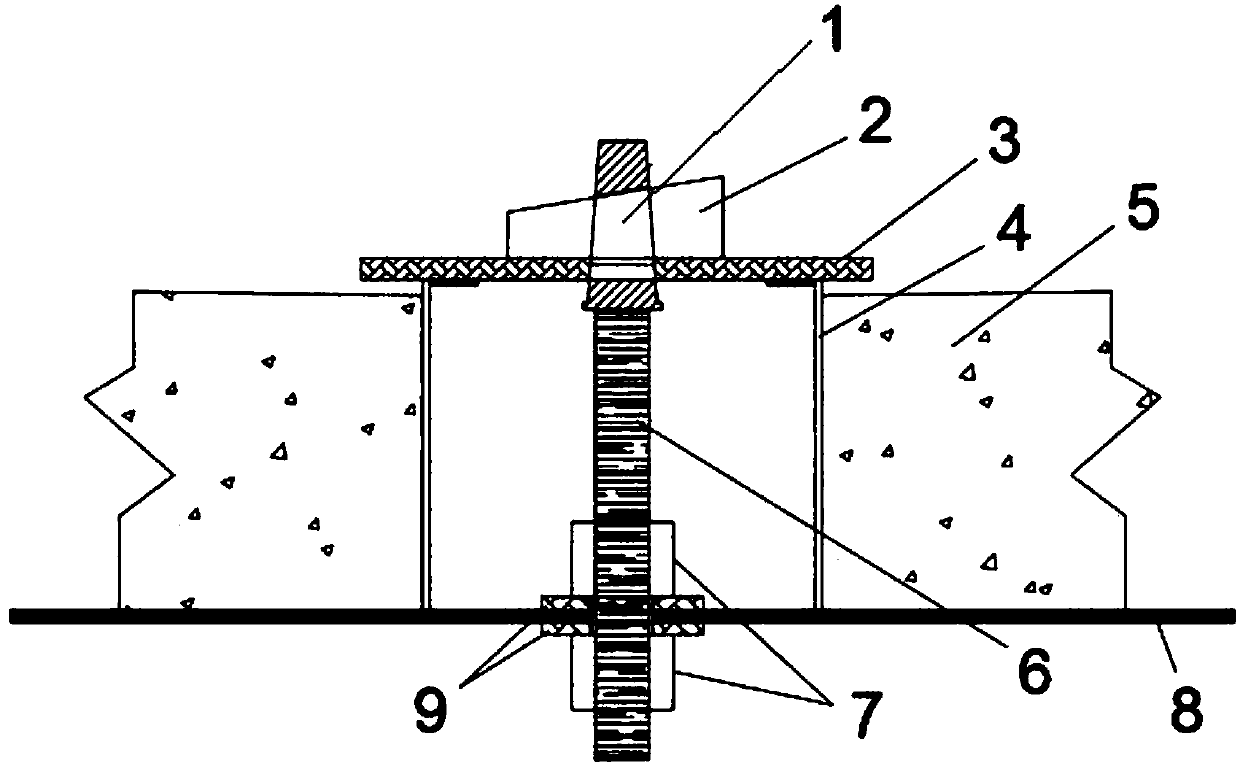

[0018] refer to figure 1 , an embodiment of the present invention is a detachable installation kit applied to embedded parts of aluminum alloy formwork, including: an aluminum alloy formwork 8; a pre-embedded hole 4; pin hole 1; a cover plate 3, the bottom surface of the cover plate 3 is provided with raised back ribs which are used to lean against the inner wall surface of the embedded part, and the symmetrically arranged ribs are arranged, and the middle part of the cover plate 3 is provided with a hole for the rod 6 to pass through. through holes; a pin 2 corresponding to the pin hole 1 on the rod 6.

[0019] Wherein, the externally threaded end of the rod 6 passes through the aluminum alloy template 8 and is threadedly connected with the nuts 7 arranged at both ends of the aluminum alloy template 8 , and a gasket 9 is arranged between the nut 7 and the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com