Cassava starch rolling machine

A technology of cassava and pressing rollers, which is applied in the direction of grain processing, etc., can solve the problems of adjusting the thickness and precision of the slurry, failing to meet the starch precision, difficult to break or cut, etc., and achieve the effect of good product quality, good energy saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

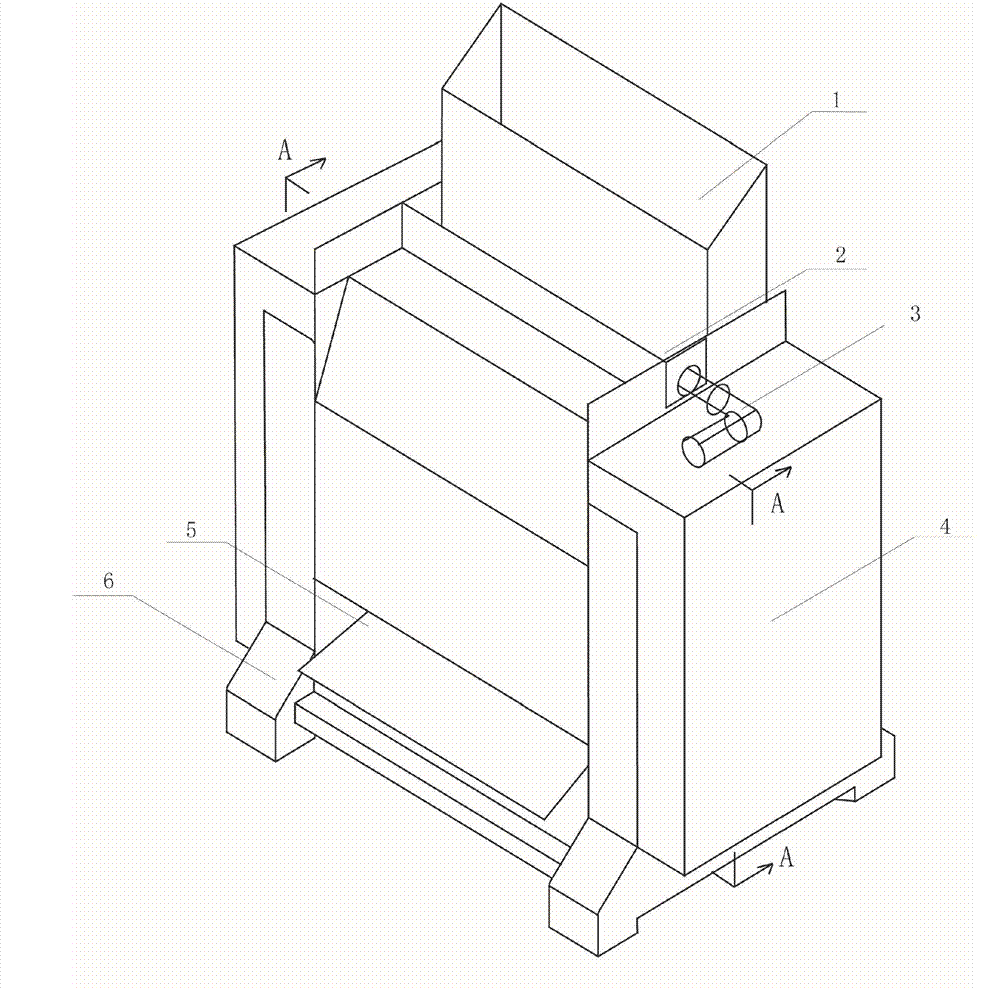

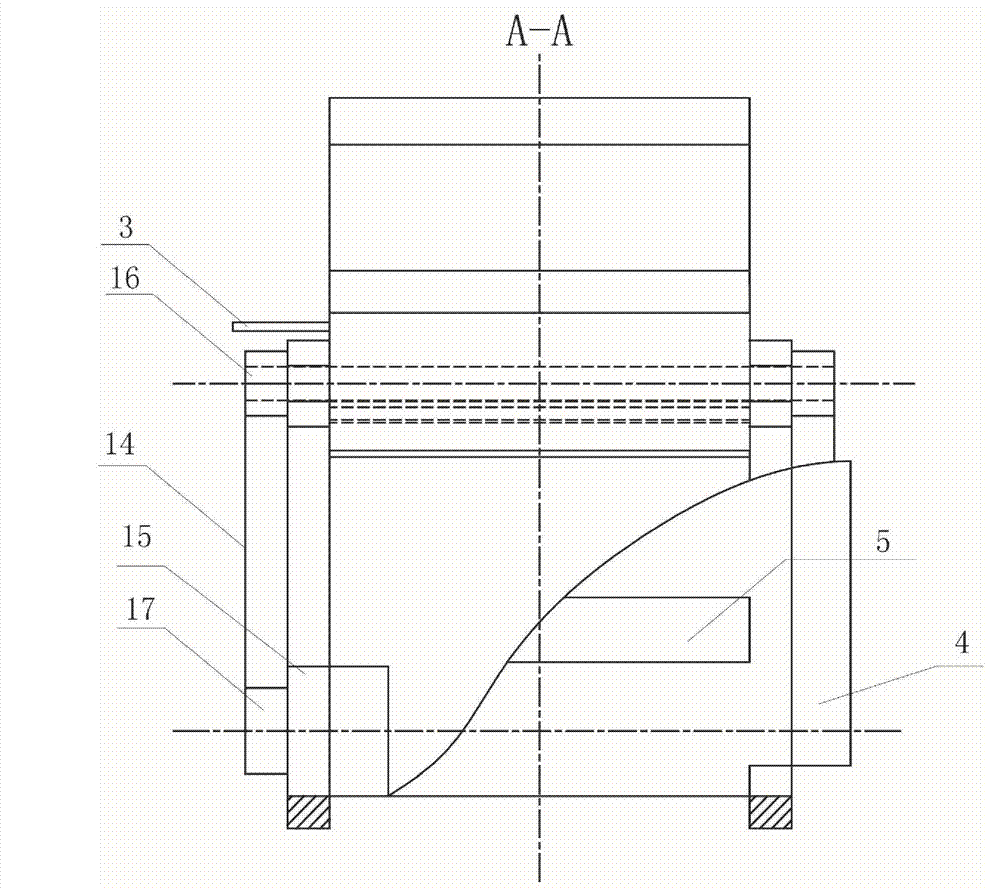

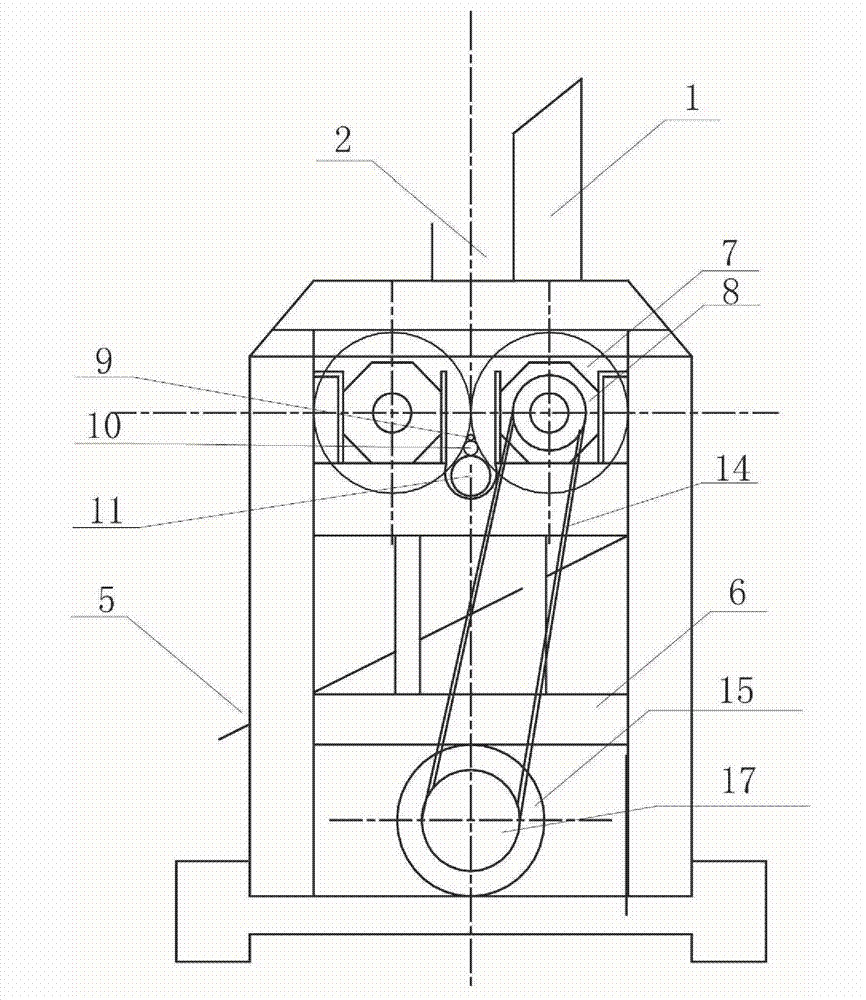

[0017] Such as Figure 1-3 As shown, the pressure roller 7 is installed in the housing 4 of the roller press, and the housing 4 is installed on the frame 6. The upper part of the housing 4 is provided with a charging port 1 and a feeding port 2, which are arranged above the pressure roller 7 , and is provided with a water injection port 3 leading to the feed port 2, and the front part of the housing 4 is a discharge port 5. The pressure roller 7 is fixed on the bearing housing 8, the fine grinding shaft 11 is tangent to the pressure roller 7 and the coarse grinding shaft 10, and the coarse grinding shaft 10 is tangent to the crushing screw shaft 9; the movement direction of the pressure roller 7 can be the same direction or Rotate in opposite directions. Bearing seat is fixed on the frame 6, and the rotating shaft of pressure roller 7 is equipped with pulley 16, and pulley 16 is connected with the pulley 17 of motor 15 by belt 14, and motor is arranged on the bottom of frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com