Resin powder bonding agent

A resin powder and binder technology, applied in the direction of adhesive, monocarboxylate copolymer adhesive, adhesive type, etc., can solve the problem of difficult production control, high material cost of special monomers, high molecular weight polyester The problem of high production cost, to achieve the effect of ensuring spreadability and adhesion, low cost and easy synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

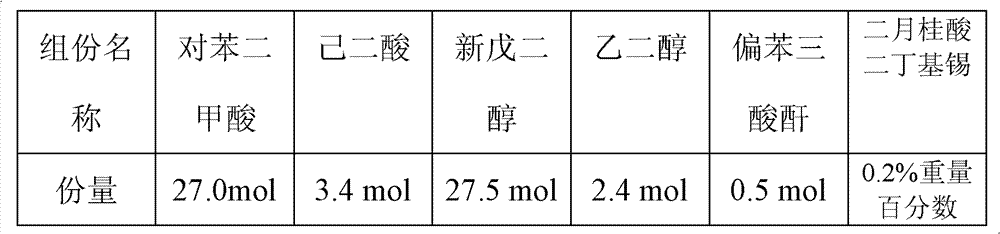

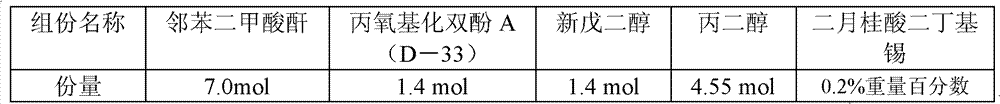

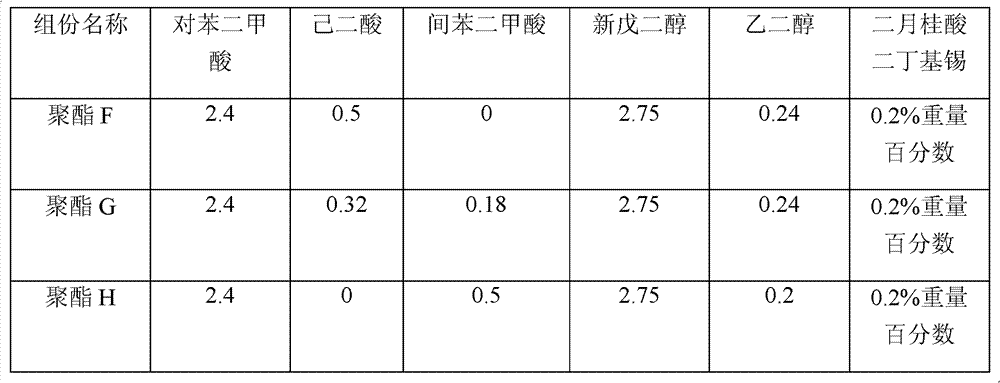

[0033] The synthesis of polyester is a very mature technology, and the polyester resin with the required softening point can be obtained by adjusting the amount of different alcohols, acids or anhydride monomers. The synthetic formula of polyester A and polyester B is as follows:

[0034]

[0035] The synthesis process of polyester A is: add the above raw materials into the reaction kettle at one time, pass nitrogen, stir, slowly raise the temperature to 140°C for 3 hours, continue to raise the temperature to 240°C, and react until the acid value is 35 and the hydroxyl value is 5. When the temperature is about to cool down, the material is discharged. Its softening point is 105°C and its molecular weight is 2800.

[0036] The synthesis process of polyester B is: add the above raw materials into the reaction kettle at one time, pass nitrogen, stir, slowly raise the temperature to 140°C for 3 hours, continue to heat up to 240°C, and react until the acid value is 50 and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com