An electrochemical method for preparing tungsten trioxide nanosheets

A tungsten trioxide, electrochemical technology, applied in the direction of nanotechnology, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of low utilization rate of metal anode, single structure, no economic benefits, etc., and achieve low requirements for reaction equipment , cost-effective, and structured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

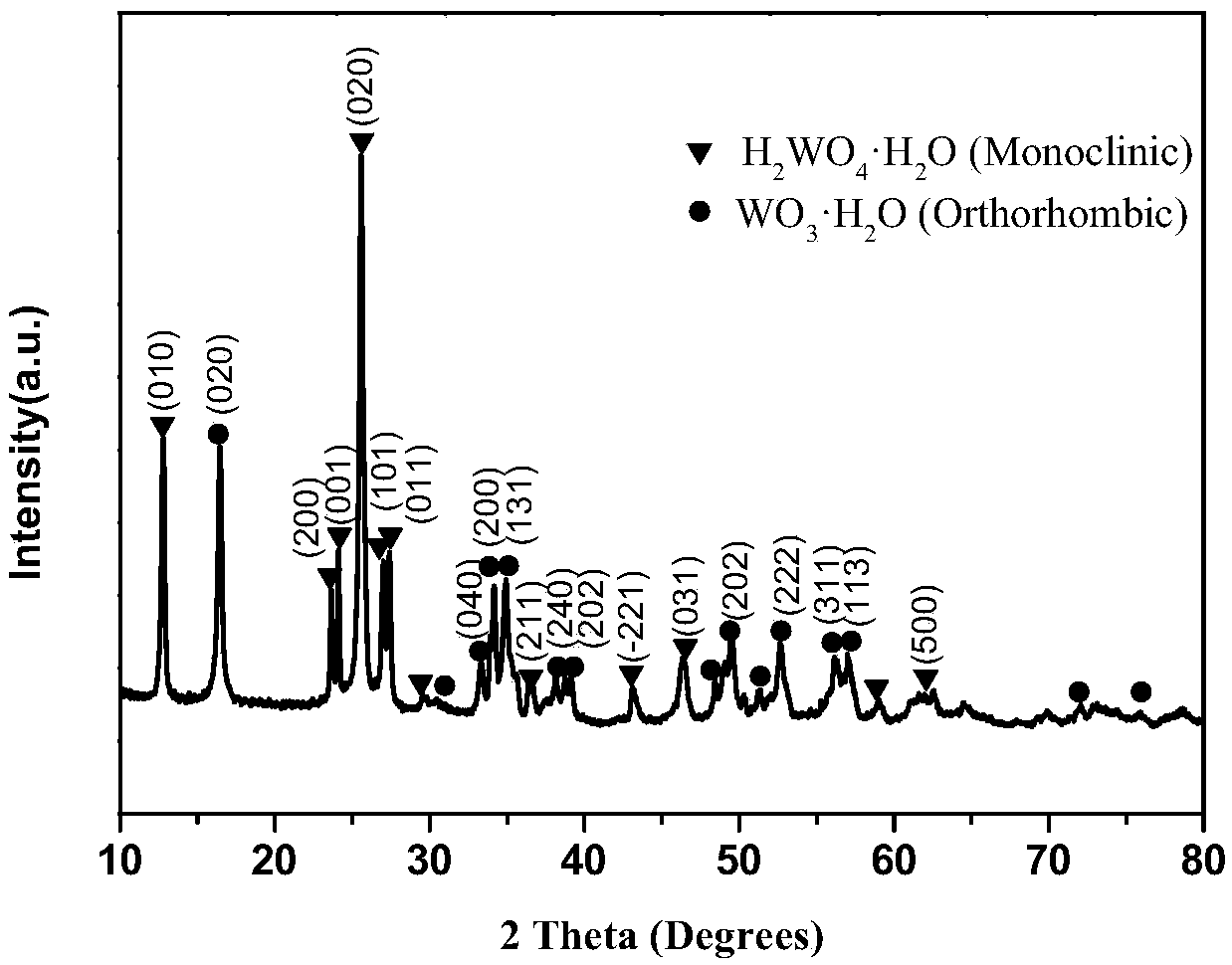

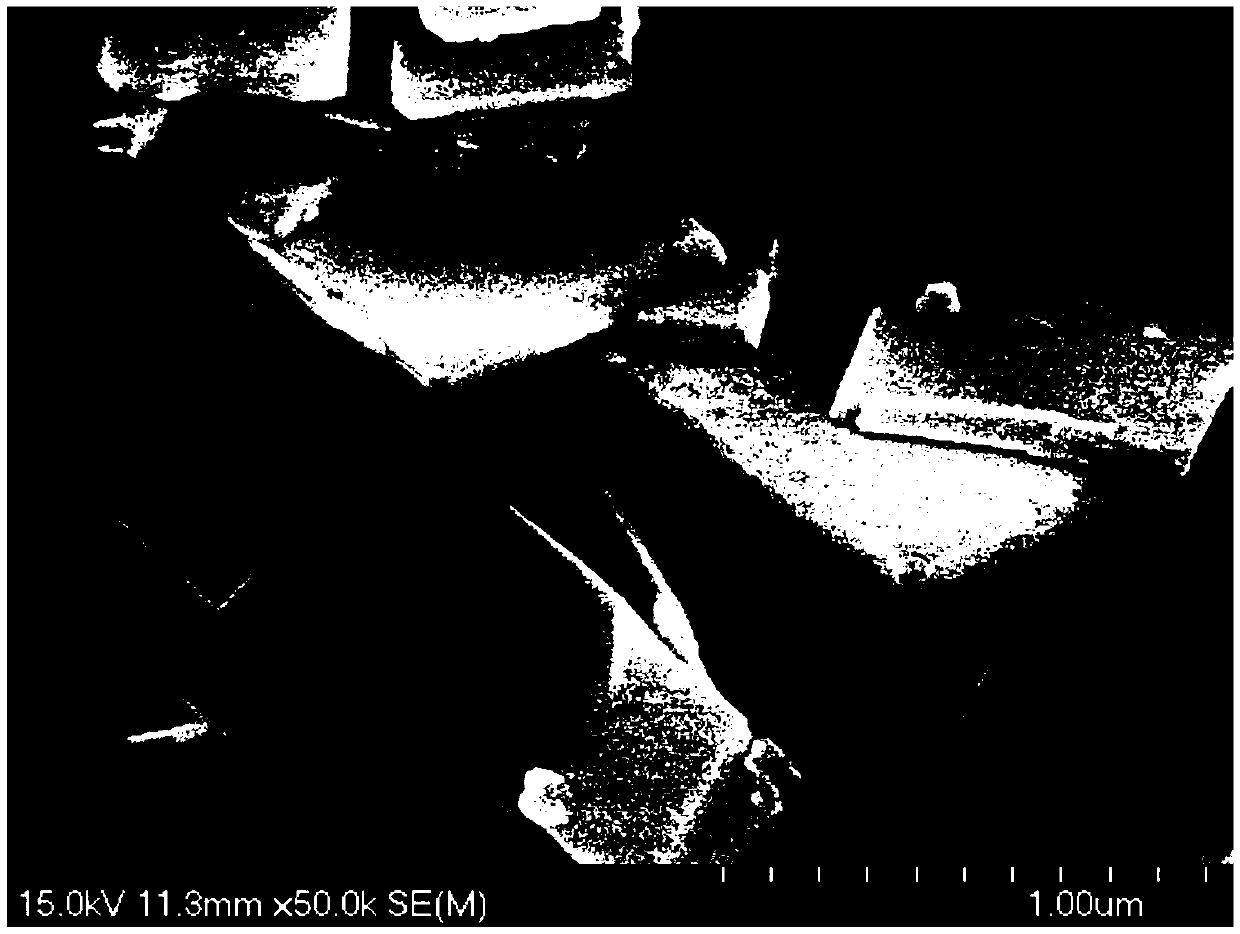

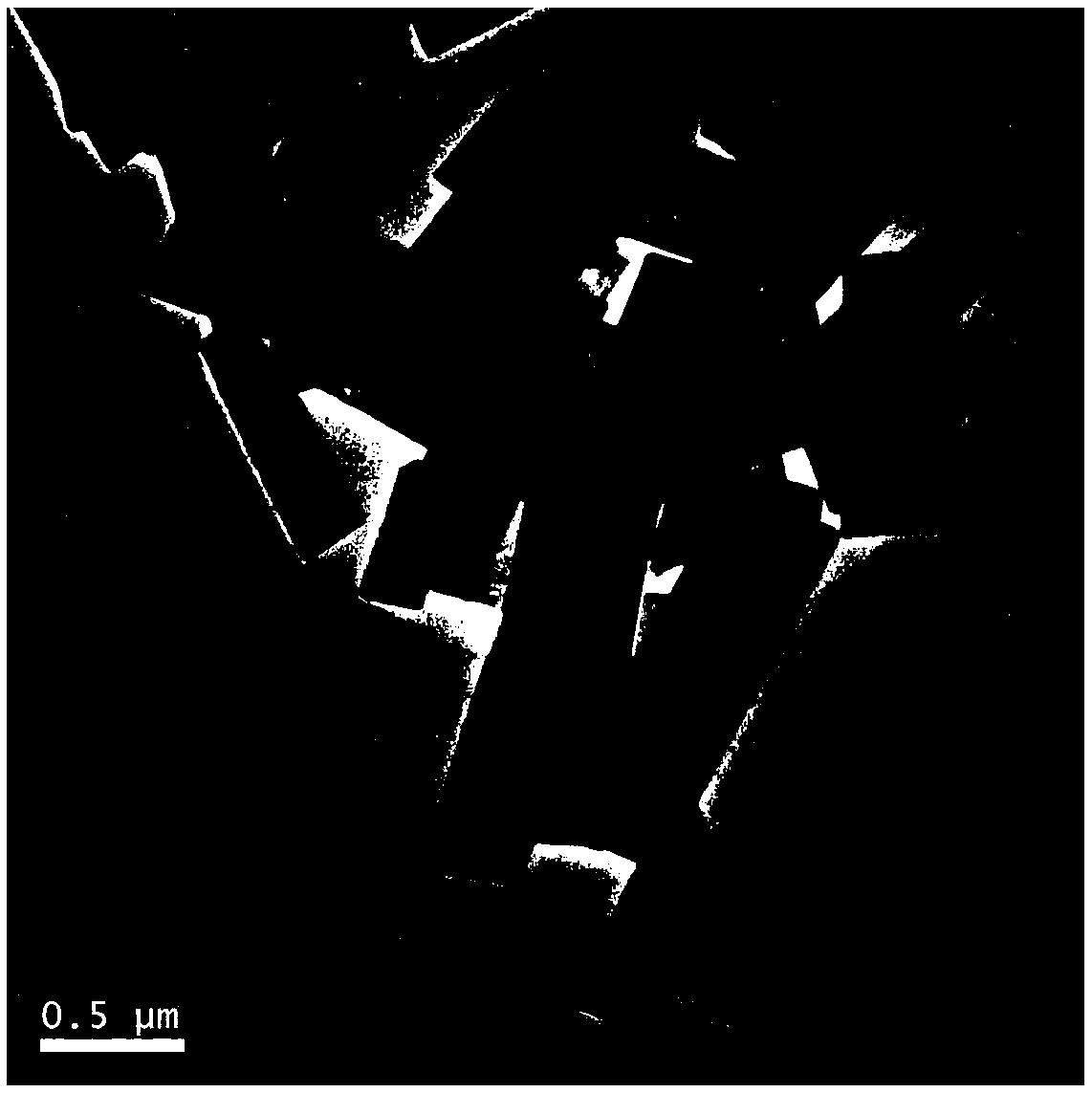

[0024] Cut the tungsten sheet with a thickness of 0.085mm into 1×1cm 2 The specifications were ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, rinsed with deionized water and dried to obtain a metal tungsten electrode after degreasing; the ionic liquid 1-ethyl-3 methylimidazolium tetrafluoroboron Salt ([EMim]BF 4 ) 0.6mL and 12mL of deionized water were added in 47.4mL of ethylene glycol to obtain an electrolyte solution (wherein the volume fraction of ionic liquid was 1%, and the volume fraction of deionized water was 20%). Use tungsten sheet as anode, titanium sheet (thickness 0.2mm, specification 2×2cm 2 ) as the cathode, put it into the electrolyte, keep the electrode distance at 1.5cm, control the temperature of the electrolyte at 25°C, and oxidize it at 20V until the tungsten is completely dissolved and oxidized into powder (8h); collect the solid powder, deionize Washing with water, filtering, and drying to obtain the product tungsten tr...

Embodiment 2

[0027] Cut the tungsten sheet with a thickness of 0.085mm into 1×1cm 2 The specifications were ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, rinsed with deionized water and dried to obtain a metal tungsten electrode after degreasing; the ionic liquid 1-ethyl-3 methylimidazolium tetrafluoroboron Salt ([EMim]BF 4 ) 0.6mL and 12mL of deionized water were added in 47.4mL of ethylene glycol to obtain an electrolyte solution (wherein the volume fraction of ionic liquid was 1%, and the volume fraction of deionized water was 20%). Use tungsten sheet as anode, titanium sheet (thickness 0.2mm, specification 2×2cm 2 ) as the cathode, put it into the electrolyte, keep the distance between the electrodes at 1.5cm, control the temperature of the electrolyte at 100°C, oxidize at 20V until the tungsten is completely dissolved, and oxidize into powder (2h); collect the solid powder, deionize Washing with water, filtering, and drying to obtain tungsten trioxid...

Embodiment 3

[0029] Cut the tungsten sheet with a thickness of 0.085mm into 1×1cm 2 The specifications were ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, rinsed with deionized water and dried to obtain a metal tungsten electrode after degreasing; the ionic liquid 1-ethyl-3 methylimidazolium tetrafluoroboron Salt ([EMim]BF 4 ) 0.6mL and 12mL of deionized water were added in 47.4mL of ethylene glycol to obtain an electrolyte solution (wherein the volume fraction of ionic liquid was 1%, and the volume fraction of deionized water was 20%). Use tungsten sheet as anode, titanium sheet (thickness 0.2mm, specification 2×2cm 2 ) as the cathode, put it into the electrolyte, keep the electrode distance at 1.5cm, control the temperature of the electrolyte at 0°C, and oxidize it at 20V until the tungsten is completely dissolved and oxidized into powder (24h); collect the solid powder, deionize Washing with water, filtering, and drying to obtain tungsten trioxide nanos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com