Adjustment process for coaxiality of pipe clamp

A technology of coaxiality and pipe clamping, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of long operation time and insufficient flexibility of operation mode, so as to improve operation efficiency, flexible operation mode and reduce cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

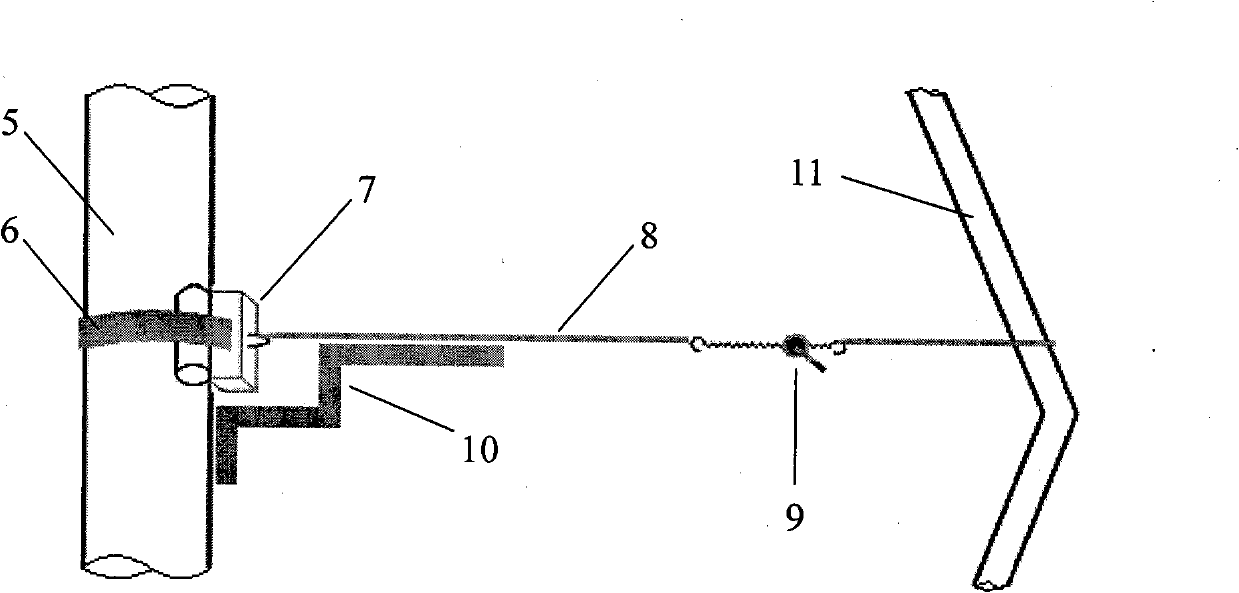

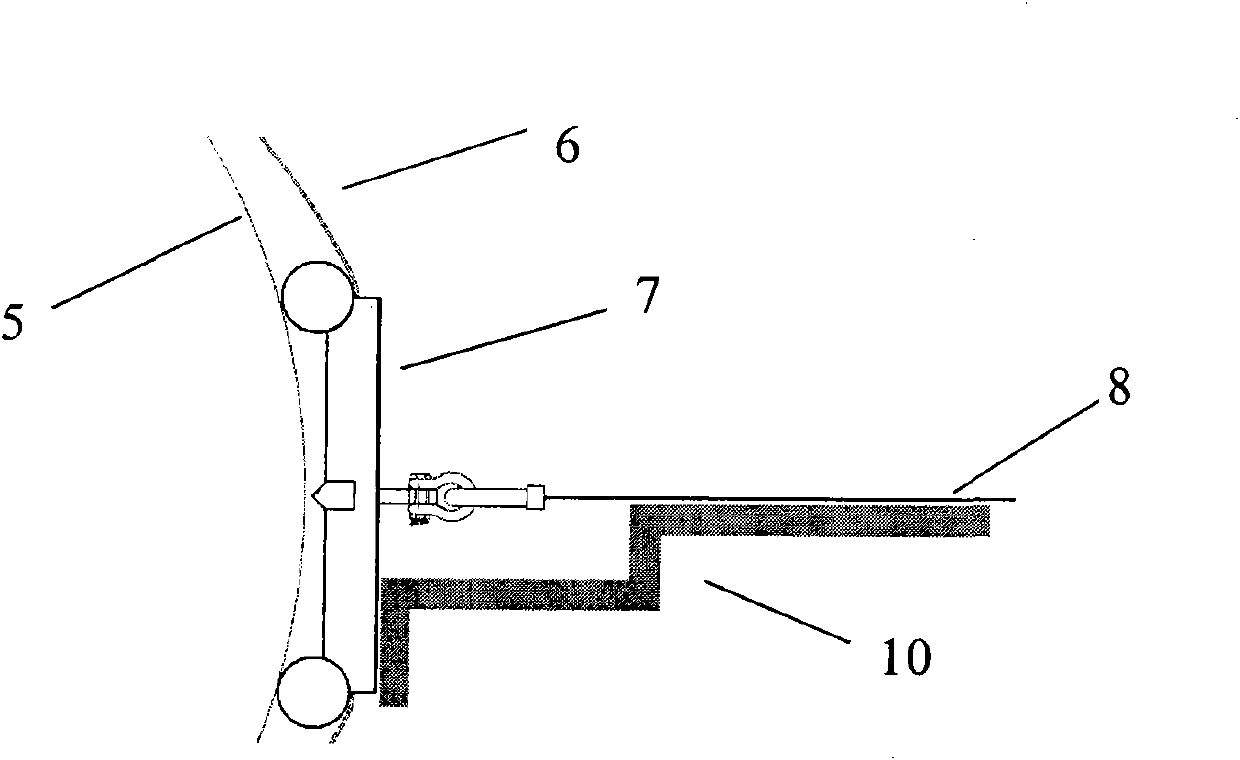

[0047] In order to simplify the adjustment process of the coaxiality of the tube clamp, the adjustment tools such as the reference rope 8, the reference rope positioning bracket 7, the scale 10 for calibrating the clamp position, and the calibration crutch 15 are respectively prefabricated for standby.

[0048] The present invention comprises the following steps:

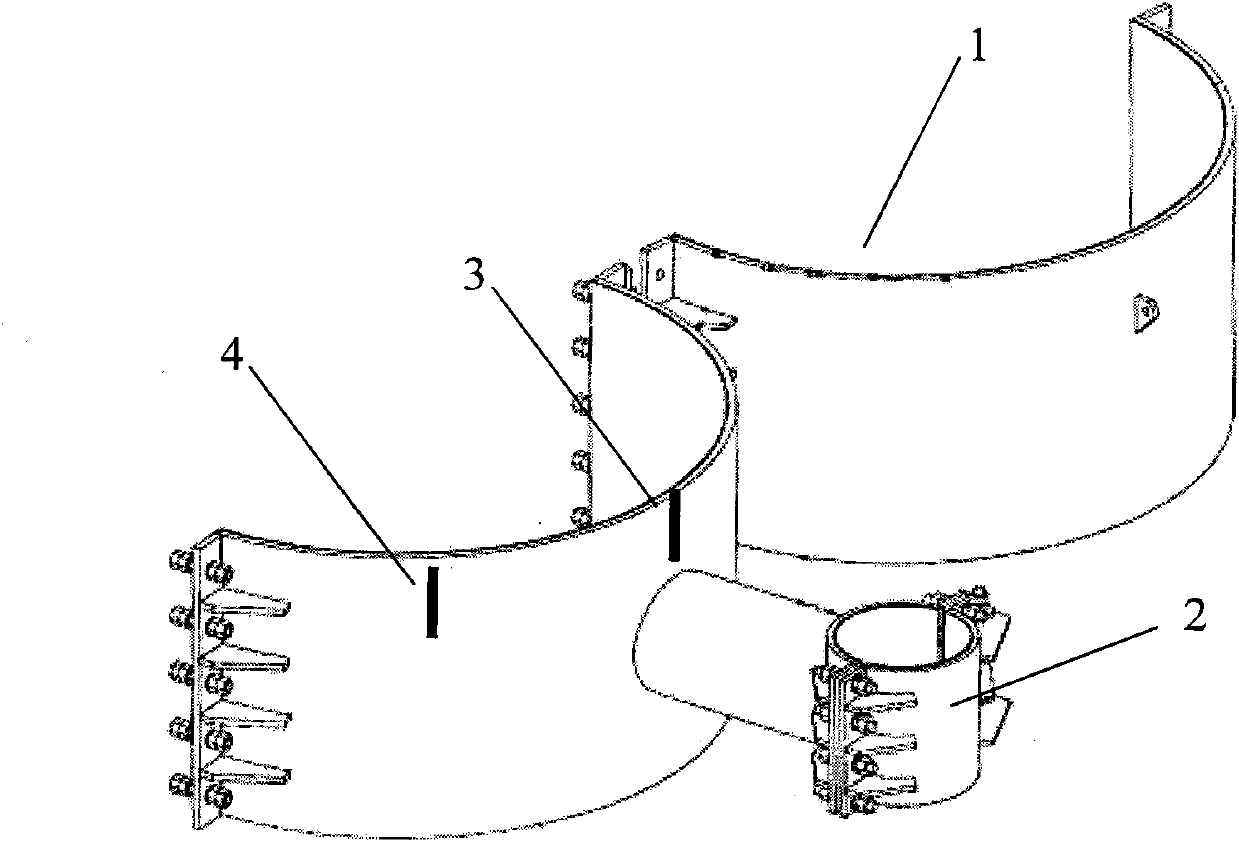

[0049] (1) Install and fix the large tube clamp 1 in the tube clamp on the jacket leg 5;

[0050] (2) Use measuring tools to assist in adjusting the azimuth of the pipe clamp to reach the design azimuth angle of 12;

[0051] (3) According to the same operation mode, install all the pipe clips on the jacket leg 5 and adjust the azimuth of the pipe clips to reach the design azimuth angle of 12, so that the central axes of the small and medium pipe clips 2 of all the pipe clips are on the same axis, that is : Make all pipe clips reach the coaxiality.

[0052] The specific operation steps are as follows:

[0053] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com