A non-woven fabric punching forming device

A molding device, non-woven technology, applied in metal processing and other directions, can solve the problems of easily scalded non-woven fabrics, poor control of product size, punching position specifications, increased production costs, etc. The effect of easy size control and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

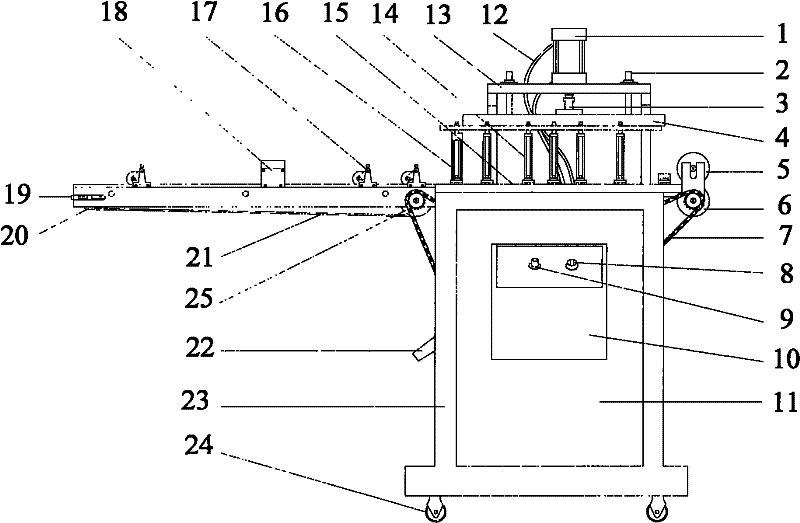

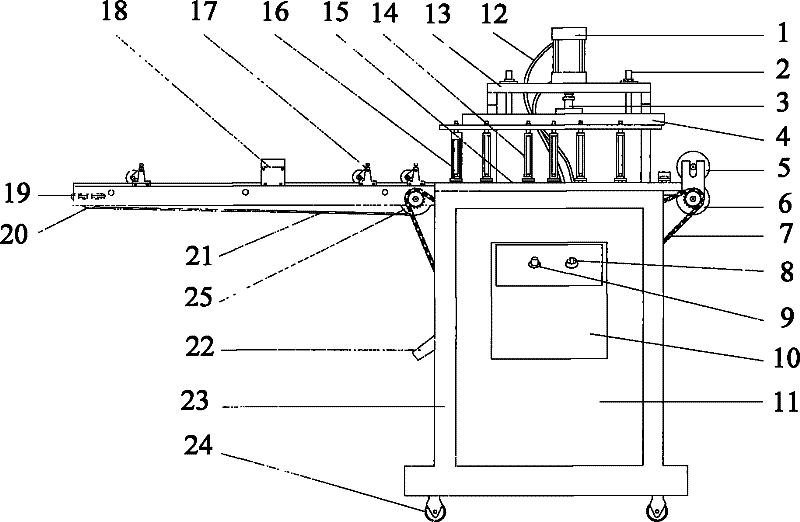

[0023] A kind of non-woven fabric punching forming device, its structure is as follows figure 1 As shown, the device includes a pneumatic stamping device, a knife die device, an electric transmission device and a motor box 23, and the pneumatic stamping device includes a cylinder block 1, a guide post 2, a cylinder connecting rod 3, a beam rod 4, an air pipe 12 and a beam frame 13 , the cylinder block 1 is arranged on the top of the beam frame 13, the cylinder block 1 is connected with the air pipe 12, the other end of the air pipe 12 is externally connected to the outdoor air compressor, the beam frame 13 is integrated with the two ends of the upper part until the column of the top platform, Be fixed on the top surface platform of motor box body 23. Die cutter device includes die die 14, scale 15 and cutter 16, die die 14 can increase or decrease the number of die dies according to product needs, and adjust the distance between die dies, the upper end is connected with beam b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com