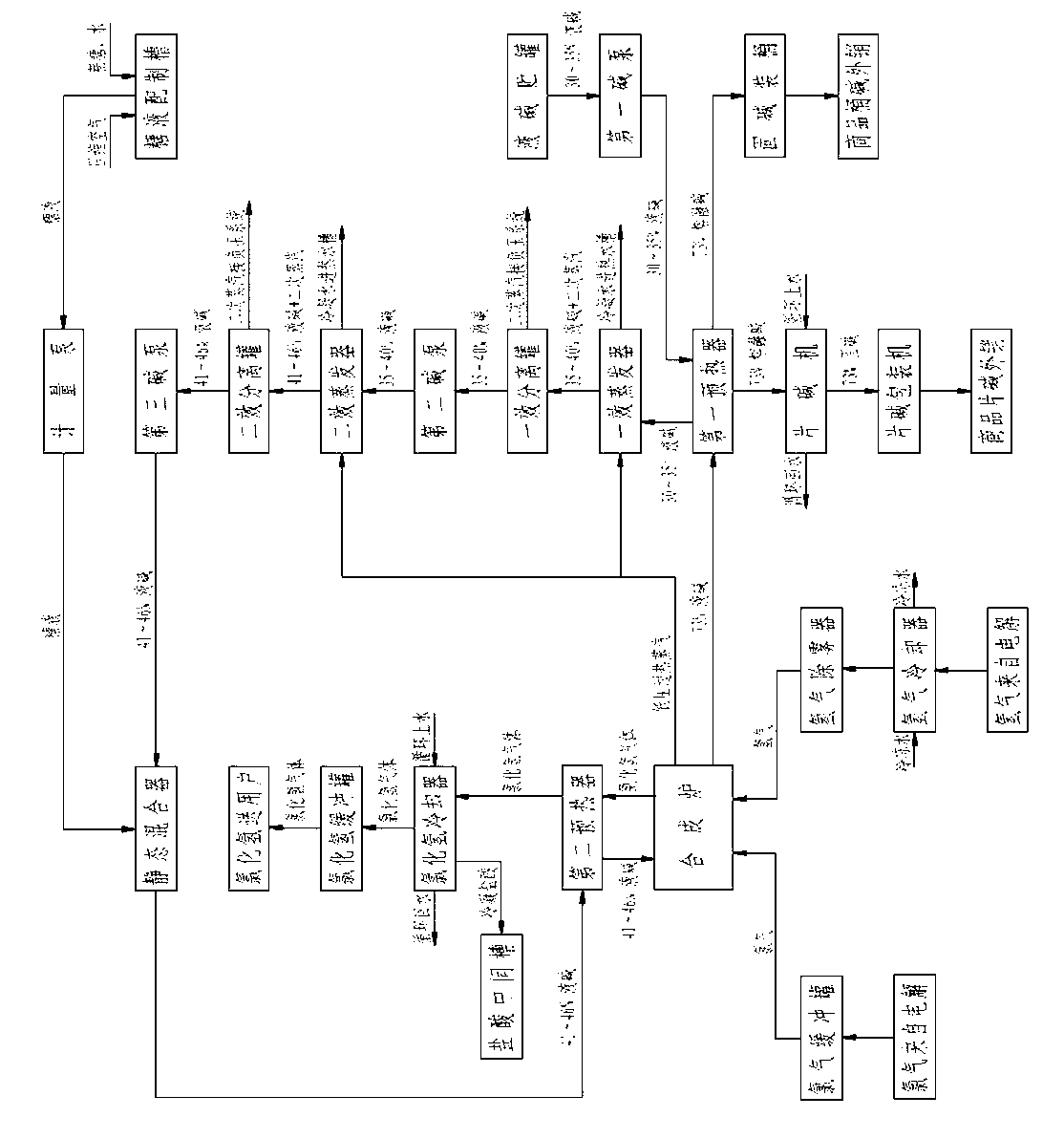

Method and device for performing alkali concentration by utilizing synthesis waste heat of hydrogen chloride

A hydrogen chloride, hydrogen chloride gas technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of complex equipment structure and large number of single equipment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

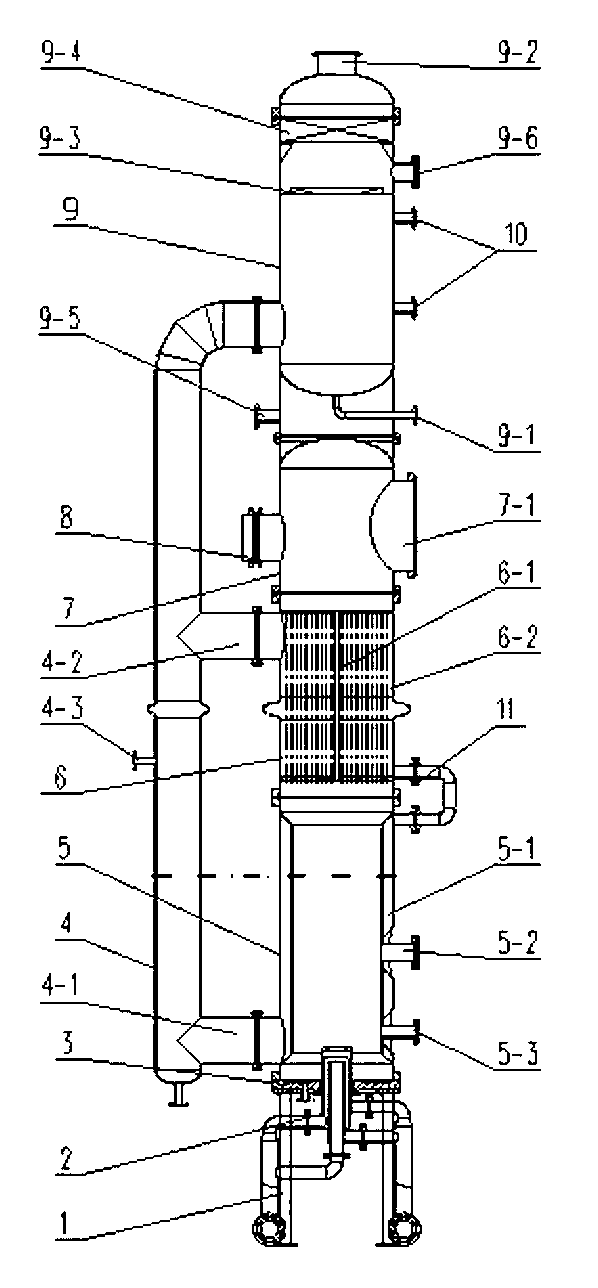

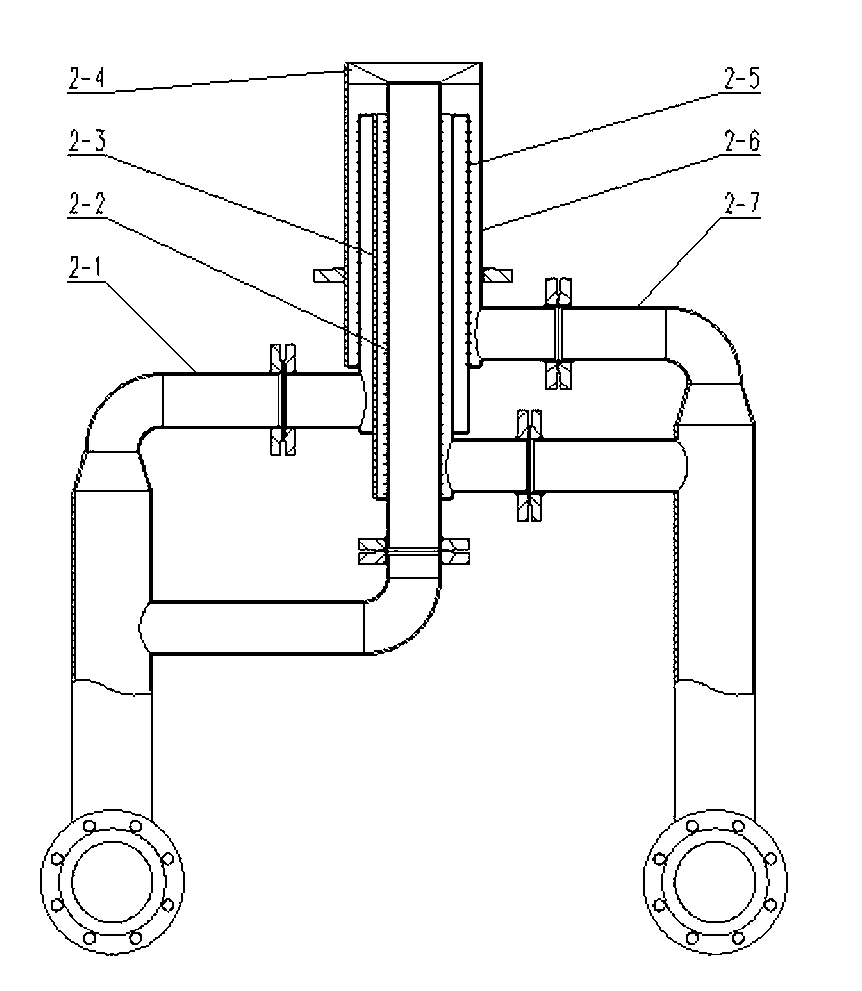

[0018] The invention provides a method for alkali concentration using the waste heat of hydrogen chloride synthesis, comprising the following steps: preheating the liquid alkali with the first concentration in the first preheater, and then performing first-effect evaporation and second-effect evaporation to obtain the second concentration of liquid caustic soda; the second concentration of liquid caustic soda is preheated in the second preheater, and then heat exchanged with the hydrogen chloride gas synthesized by the combustion reaction to obtain the third concentration of liquid caustic soda and low-pressure superheated steam; wherein, the first preheating The heat source of the second preheater is the third concentration liquid caustic soda, the heat source of the second preheater is the hydrogen chloride gas after heat exchange, and the heat sources of the first effect evaporation and the second effect evaporation are low-pressure superheated steam.

[0019] The technologi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com