Square steel tube lifting outside scaffold

A technology of external scaffolding and square steel pipe is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc. It can solve the problems of cumbersome scaffolding installation process, large transportation workload of consumables, and large construction site environmental pollution, and achieve fire protection. The safety effect is obvious, the innovation and development are promoted, and the frame body is upgraded quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

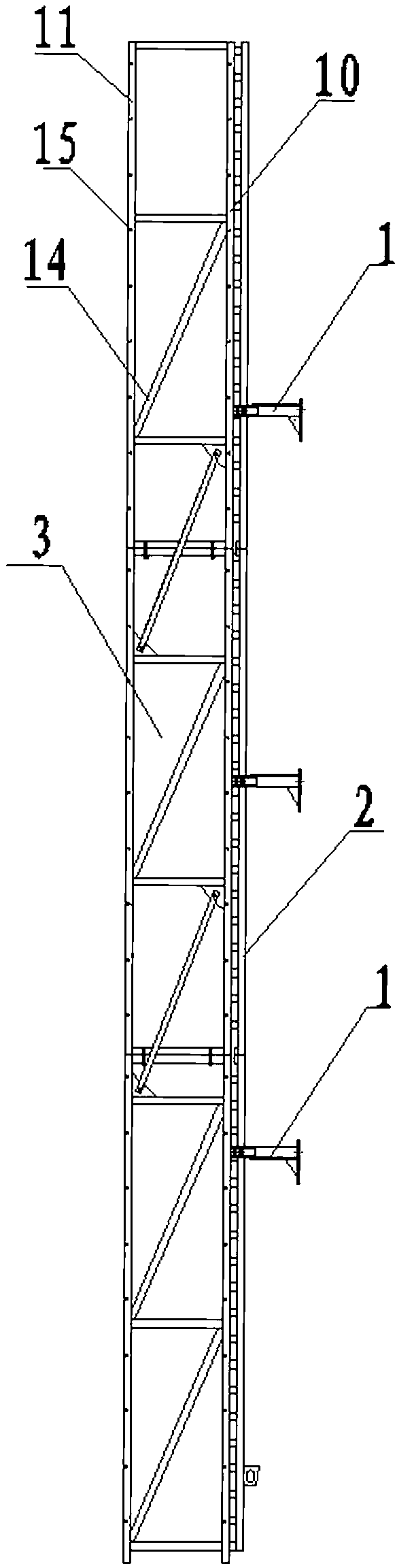

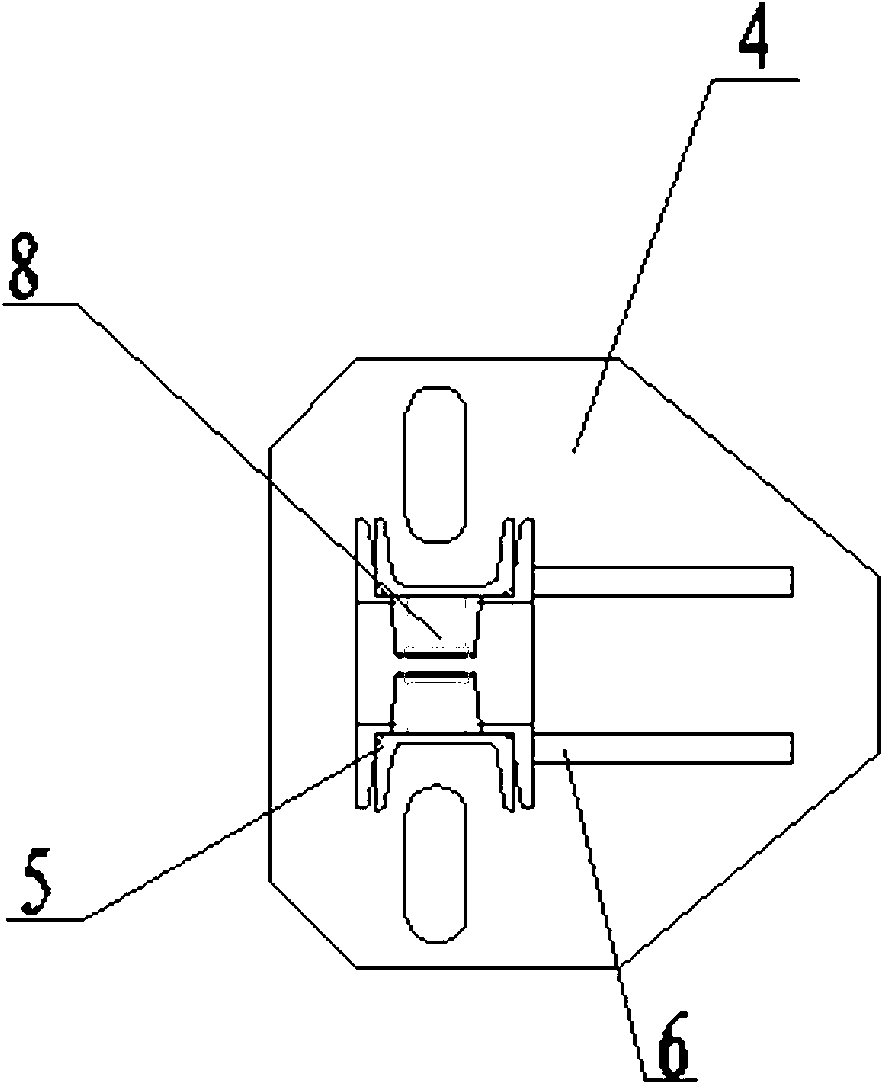

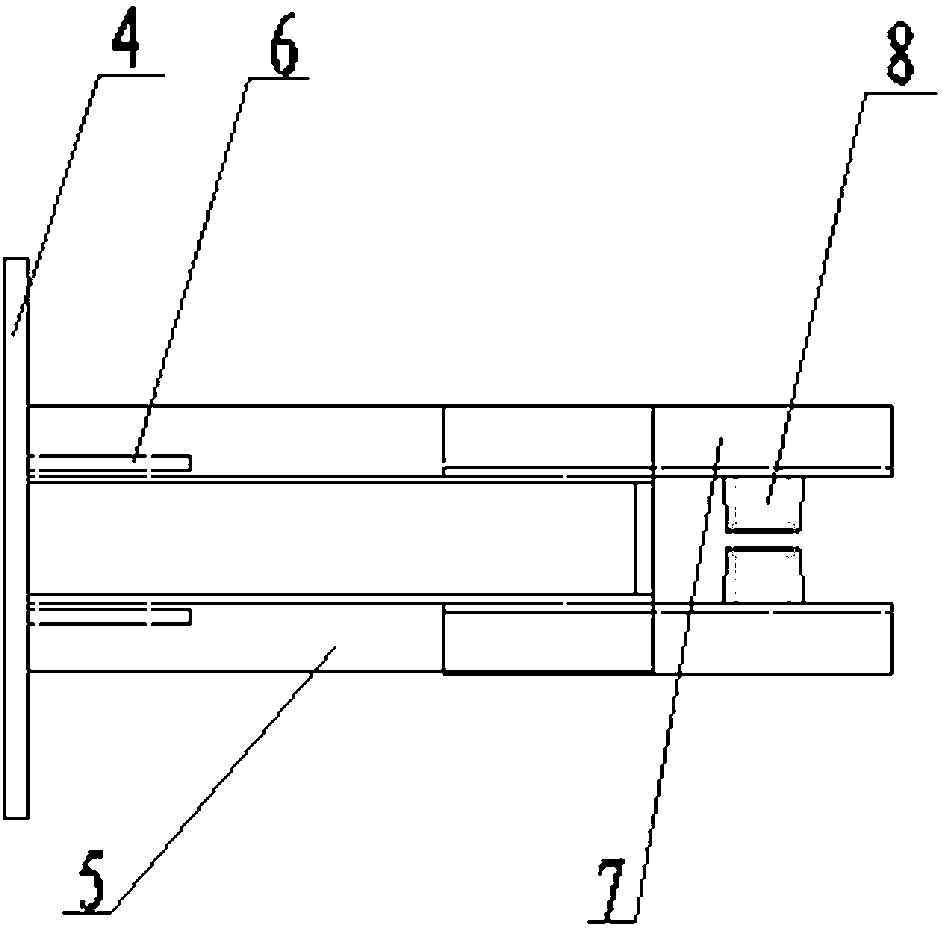

[0021] like Figure 1-9 As shown, the square steel pipe lift-type external scaffold of the present invention is composed of a lifting beam 1, a vertical main frame 2, a horizontal support frame, a frame body 3 and an anti-falling device, and the lifting beam 1 is composed of a hanging plate 4 and a channel steel 5 The hanging plate 4 is fixedly connected with the outer wall through at least two wall-through bolts, the channel steel 5 is connected with the hanging plate 4, and the root is fixedly connected with a reinforced triangular plate 6; the middle part of the lifting beam 1 is provided with an anti-falling device, and a control panel is installed below it. An electric hoist with a lifting frame; the end of the lifting beam 1 is welded with a channel steel baffle 7, and the baffle 7 is connected with a guide wheel 8, and the guide wheel 8 is located in the groove of the channel steel guide rail 9 of the vertical main frame 2. The sliding contact connection of the guide ra...

Embodiment 2

[0023] The square steel pipe lifting type external scaffolding of the present invention is used for the decoration of the face wall and external wall of the existing building. The scaffolding is a plane structure, and the height is three floors high of the building floor height, which is about 12.6 meters.

Embodiment 3

[0025] The square steel pipe lifting type external scaffolding of the present invention is used for building new buildings, and the scaffolding is a square structure, and the height is 5 floors high of the building floor height, which is about 16.2 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com