Direct-drive lifting device for three-dimensional garage

The technology of a lifting device and a three-dimensional garage is applied to the buildings, building types, buildings, etc. where cars are parked. Convenience and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

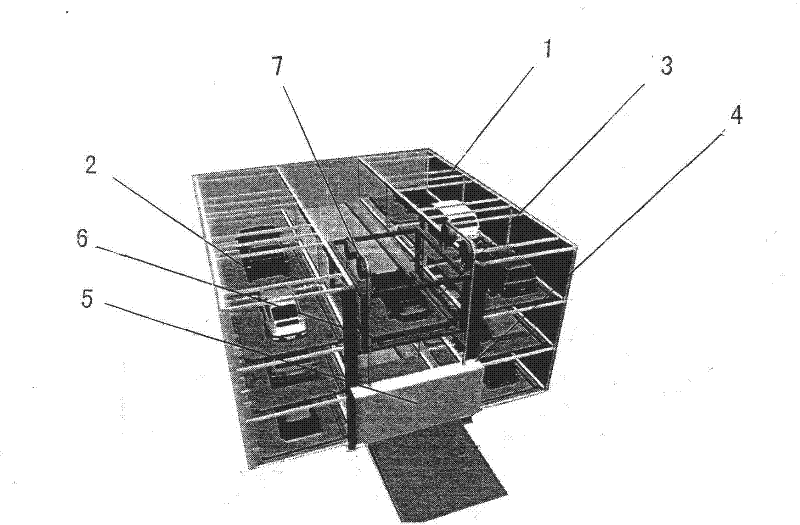

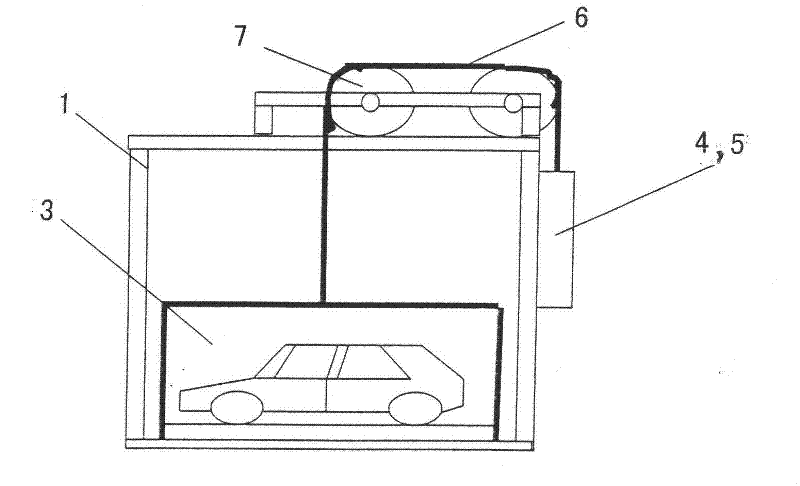

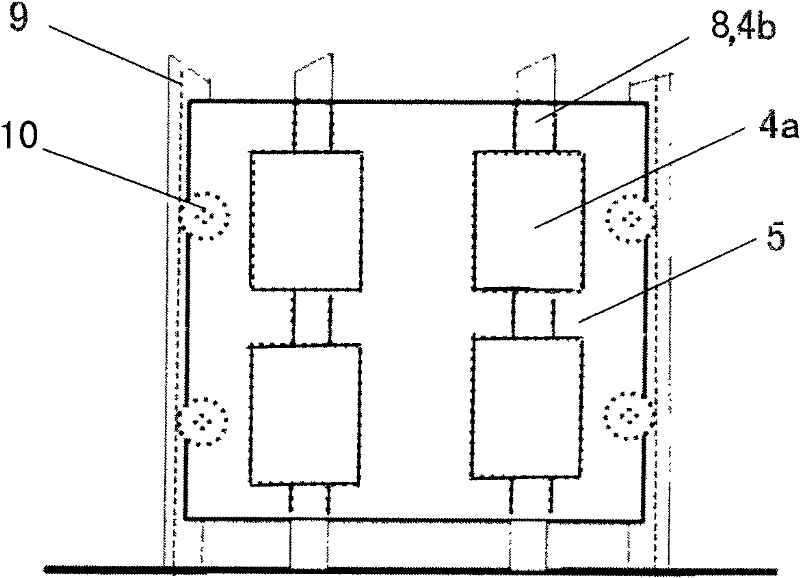

[0012] Such as Figure 1 ~ Figure 3 As shown, a direct-drive lifting device for a three-dimensional garage includes a warehouse rack 1, a parking space 2, a lifting platform 3, a direct-drive lifting linear motor 4, a counterweight 5, a counterweight belt 6, a traction wheel 7, and a warehouse rack. The vertical beam 8, the counterweight guide rail 9, and the counterweight wheel 10 are characterized in that: the direct drive lifting device is driven by a direct drive lifting linear motor 4, and the primary 4a of the direct drive lifting linear motor is installed on the lifting platform 3, and the direct drive The secondary 4b of the lifting linear motor is installed on the vertical beam 8 of the warehouse rack; the above-mentioned direct drive lifting linear motor is a flat linear motor, a cylindrical linear motor, an electric excitation induction linear motor, and a self-excited permanent magnet linear motor. One type, the number of direct-drive lifting linear motors is 1.

Embodiment 2

[0014] Such as Figure 1 ~ Figure 3 As shown, a direct-drive lifting device for a three-dimensional garage includes a warehouse rack 1, a parking space 2, a lifting platform 3, a direct-drive lifting linear motor 4, a counterweight 5, a counterweight belt 6, a traction wheel 7, and a warehouse rack. The vertical beam 8, the counterweight guide rail 9, and the counterweight wheel 10 are characterized in that: the direct-drive lifting device is driven by a direct-drive lifting linear motor 4, and the primary 4a of the direct-drive lifting linear motor is installed on the vertical beam 8 of the storage rack. The secondary 4b of the direct-drive lifting linear motor is installed on the lifting table 3; the above-mentioned direct-drive lifting linear motor is a flat linear motor, a cylindrical linear motor, an electric excitation induction linear motor, and a self-excited permanent magnet linear motor. One type, the number of direct-drive lifting linear motors is 2.

Embodiment 3

[0016] Such as Figure 1 ~ Figure 3 As shown, a direct-drive lifting device for a three-dimensional garage includes a warehouse rack 1, a parking space 2, a lifting platform 3, a direct-drive lifting linear motor 4, a counterweight 5, a counterweight belt 6, a traction wheel 7, and a warehouse rack. The vertical beam 8, the counterweight guide rail 9, and the counterweight wheel 10 are characterized in that: the direct-drive lifting device is driven by a direct-drive lifting linear motor 4, and the primary 4a of the direct-drive lifting linear motor is installed on the counterweight 5, directly The drive-type lifting linear motor secondary 4b is installed on the vertical beam 8 of the warehouse rack; the above-mentioned direct-drive lifting linear motor is a flat linear motor, a cylindrical linear motor, an electric excitation induction linear motor, and a self-excited permanent magnet linear motor One of them, the number of direct-drive lifting linear motors is 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com