Simple maintenance forklift

A simple maintenance and forklift technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient repair work, unsatisfactory installation quality, uneven force, etc., and achieve the effect of simplified lifting structure, good versatility, and guaranteed strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

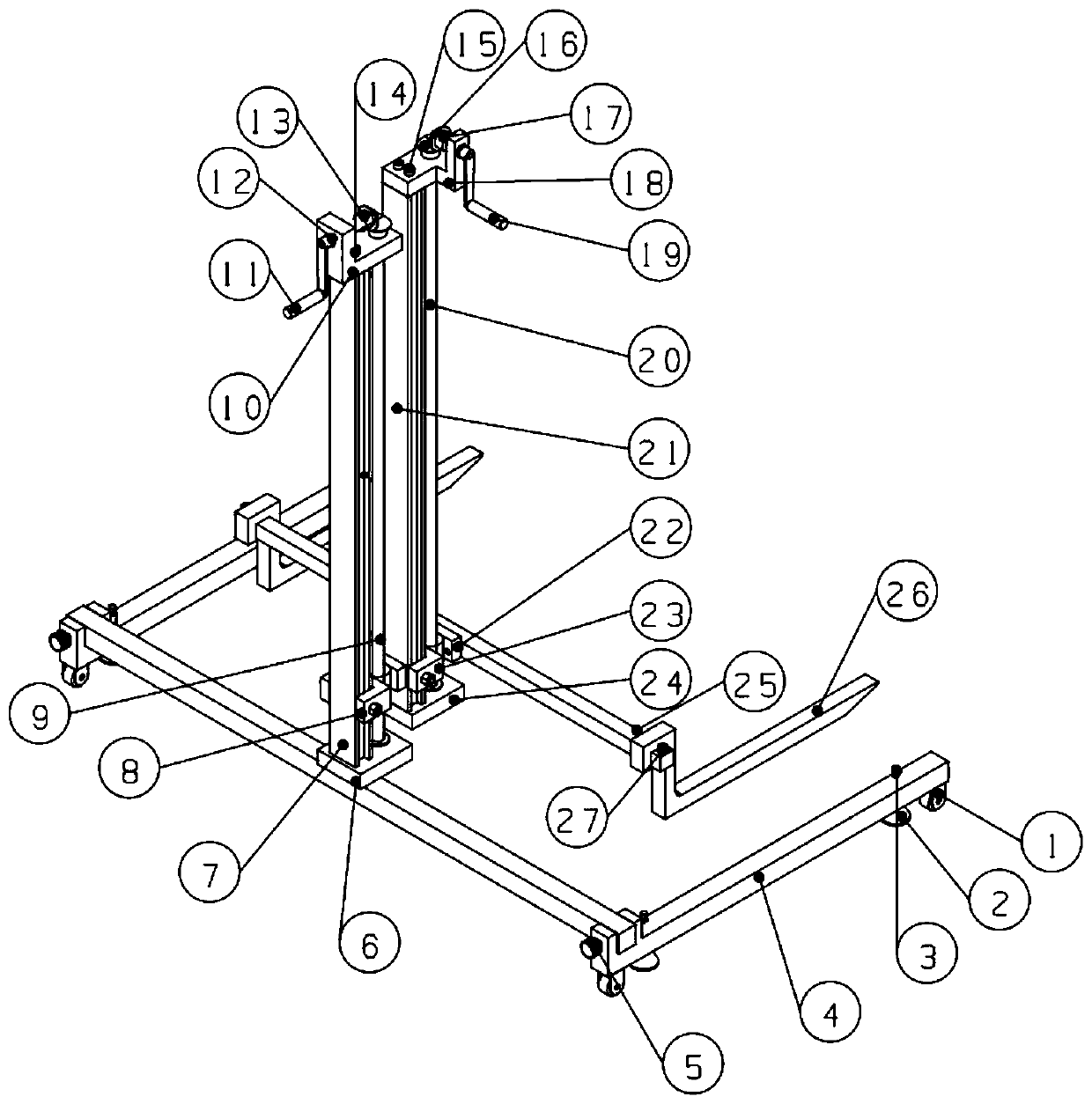

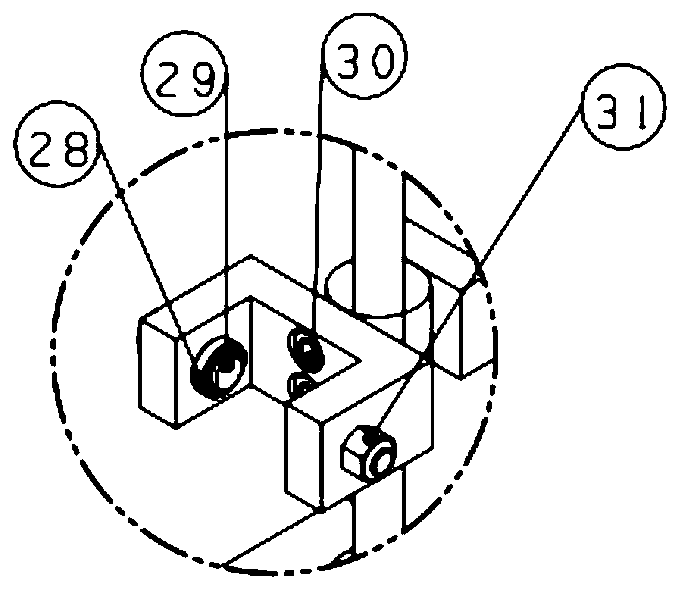

[0036] see Figure 1~3 , In an embodiment of the present invention, a simple maintenance forklift includes a support assembly that is supported on the ground, a lifting assembly for raising the height, and an installation assembly for placing to be lifted.

[0037] The support assembly includes at least two lower forks 4 arranged in parallel and a connecting strut connecting the ends of the at least two lower forks 4 with a rectangular cross-section. Rectangular groove, this kind of mortise joint is convenient for later disassembly, and can be disassembled into individual parts when carrying, and the assembly is also fast. The lower fork 4 is provided with a lower fork adjustment for limiting the position of the connecting strut The fixing screw 5, when in use, slides on the lower fork 4 through the connecting strut, thereby adjusting the distance between the two lower forks 4.

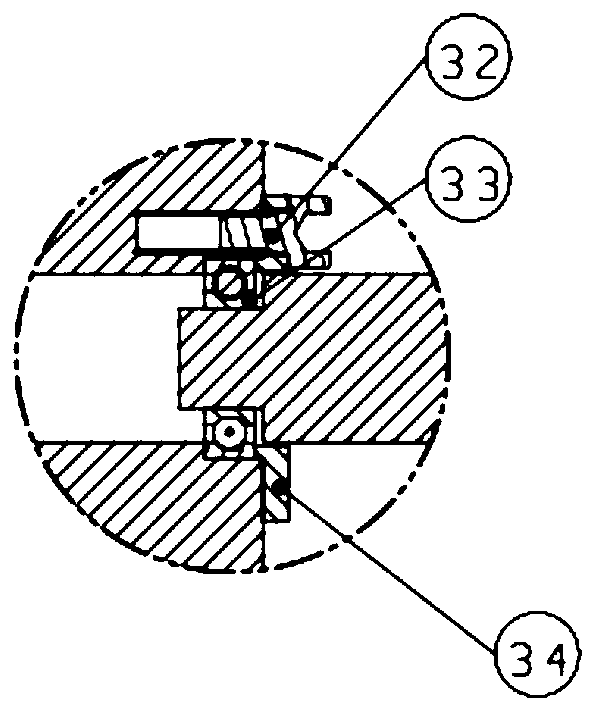

[0038] The lifting assembly includes a first lifting mechanism installed on the support assembly ...

Embodiment 2

[0048] The difference from Embodiment 1 is that in order to make the second lifting mechanism lift more smoothly, the outer side of the inner lifting guide rail 21 is connected to a guide rod arranged in parallel with the outer screw rod 9, and the upper and lower end surfaces of the outer bevel gear seat 10 run through There is a guide hole in sliding contact with the guide rod, and through the auxiliary guidance of the guide rod and the guide hole, the second lifting mechanism can be lifted and lowered more smoothly.

Embodiment 3

[0050] The difference from Embodiment 2 is that in order to realize the fine adjustment of the inclination angle of the whole device to match the installation of the parts to be installed, the two ends of the lower fork 4 are also provided with a fulcrum adjustment mechanism for adjusting the height of the fulcrum, and the fulcrum adjustment The mechanism includes a support foot adjustment screw 3 that runs through the upper and lower end faces of the lower fork 4 and an adjustable support foot 2 that is arranged at the lower end of the support foot adjustment screw 3 for supporting the ground. Later, by rotating the support foot adjustment screw 3, the adjustable support foot 2 support height, and then adjust the support inclination angle of the entire support assembly, in order to further facilitate the adjustment of the adjustable support foot 2, the support foot adjustment screw 3 can be replaced by a jack, so that even after supporting the heavy object to be installed, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com