Y-shaped ventilation method

An air inlet, one way technology, applied in the ventilation of mines/tunnels, earth-moving drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

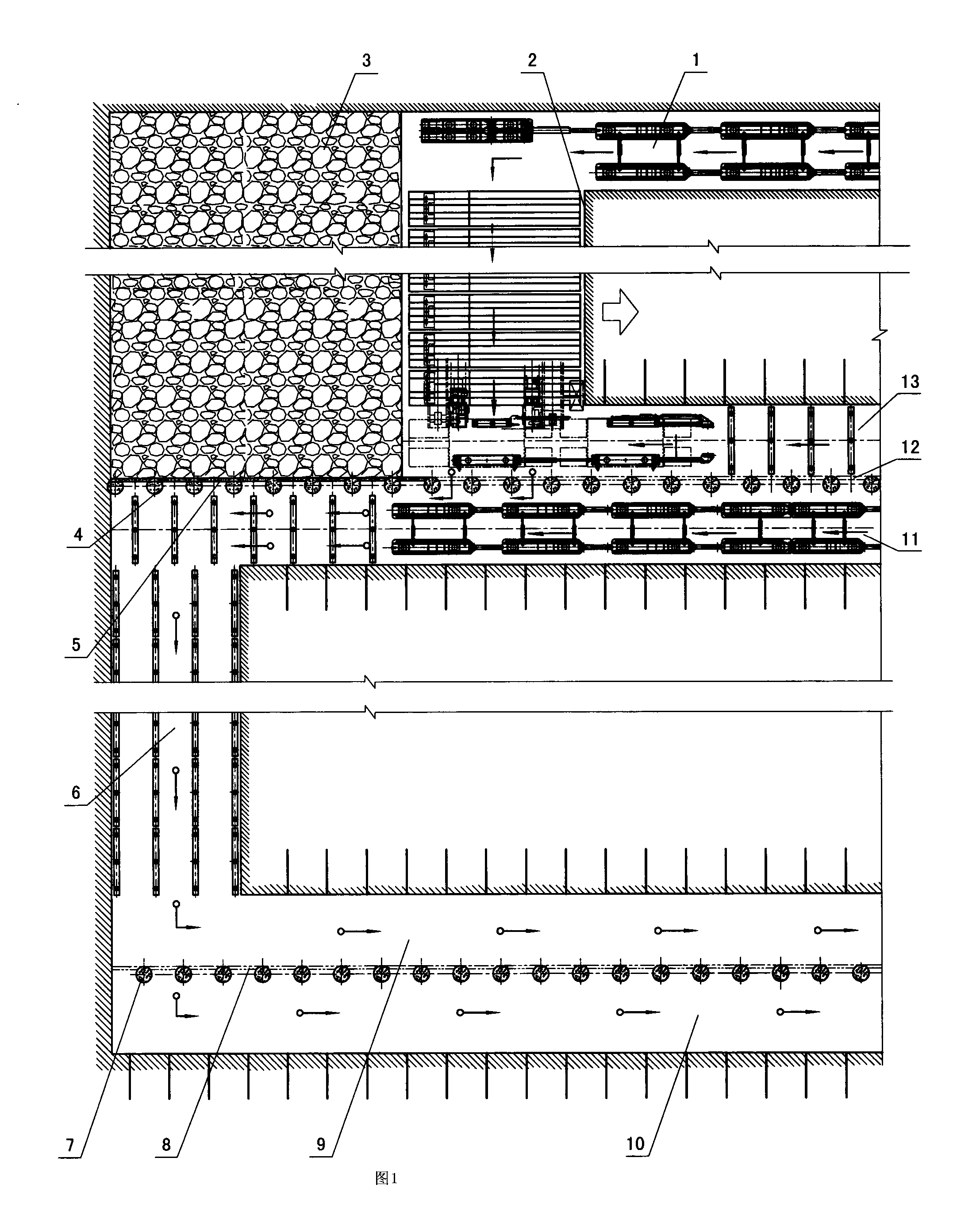

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] Shown in the accompanying drawings is the ventilation route of a "Y" type ventilation method of the present invention and the arrangement of concrete pier columns and partition walls in the roadway of the new method of retaining roadways along the gob in the mining face.

[0024] In the upper half of the figure, there are mining face 2 in this section and its track trough 1, transport trough 13, goaf entry 11, goaf 3, and the area between transport trough 13 and goaf entry 11 Concrete pier column 4, partition wall 5 and 12 in the lane of this section. Among them, the partition wall 12 is the part of the partition wall to be built; the gob-side entry 11 in this section is also the track trough of the mining face in the next section. In the lower half of the figure, there are cut-outs 6, transport chute 9, and gob-side entry 11 in the mining face of the next secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com