Steam power engine

A technology of prime mover and steam, which is applied to steam engine devices, engine components, machines/engines, etc., to achieve the effect of suppressing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

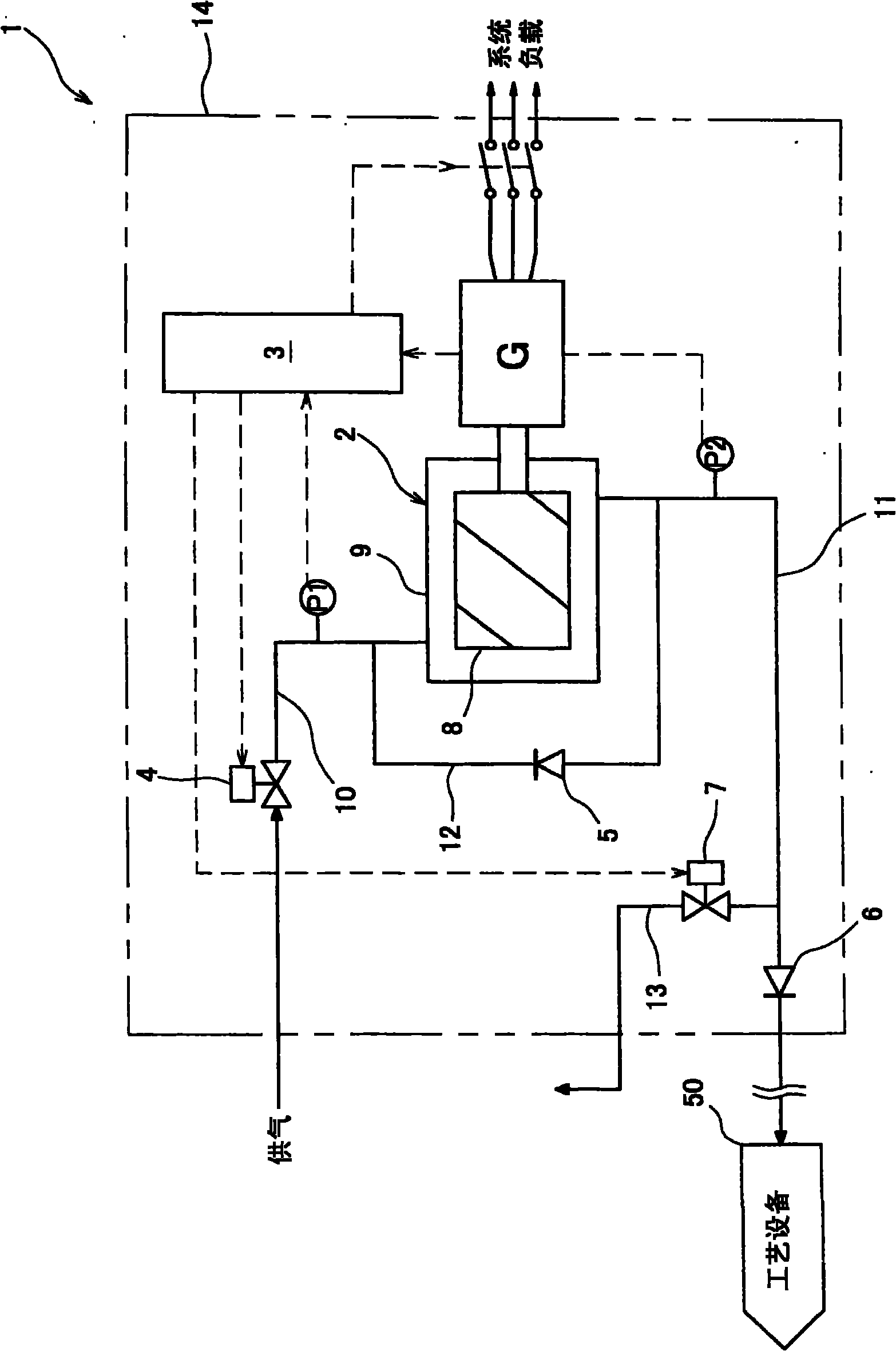

[0040] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In the following description, the steam prime mover of the present invention is exemplified as a steam prime mover for driving a generator, but the steam prime mover of the present invention can also be used as a prime mover for driving equipment other than a generator such as a compressor. motivation.

[0041] (Structure of a steam generator equipped with a steam prime mover)

[0042] Such as figure 1 As shown, the steam generator 1 mainly includes a positive displacement steam turbine 2 and a generator G connected to the positive displacement steam turbine 2 . The positive displacement steam turbine 2 and the generator G are accommodated in the unit cover 14 together with other auxiliary equipment (the control panel 3 and the like, details will be described later). Among the plurality of devices constituting the steam generator 1 , a group of devices other th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com