A dual-shaft smoke exhaust fire check valve

A check valve, double shaft technology, applied in the direction of control valve, safety valve, balance valve, etc., can solve the problems of complex processing, no reset function, difficult to find the position of the rotating shaft, etc., to achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

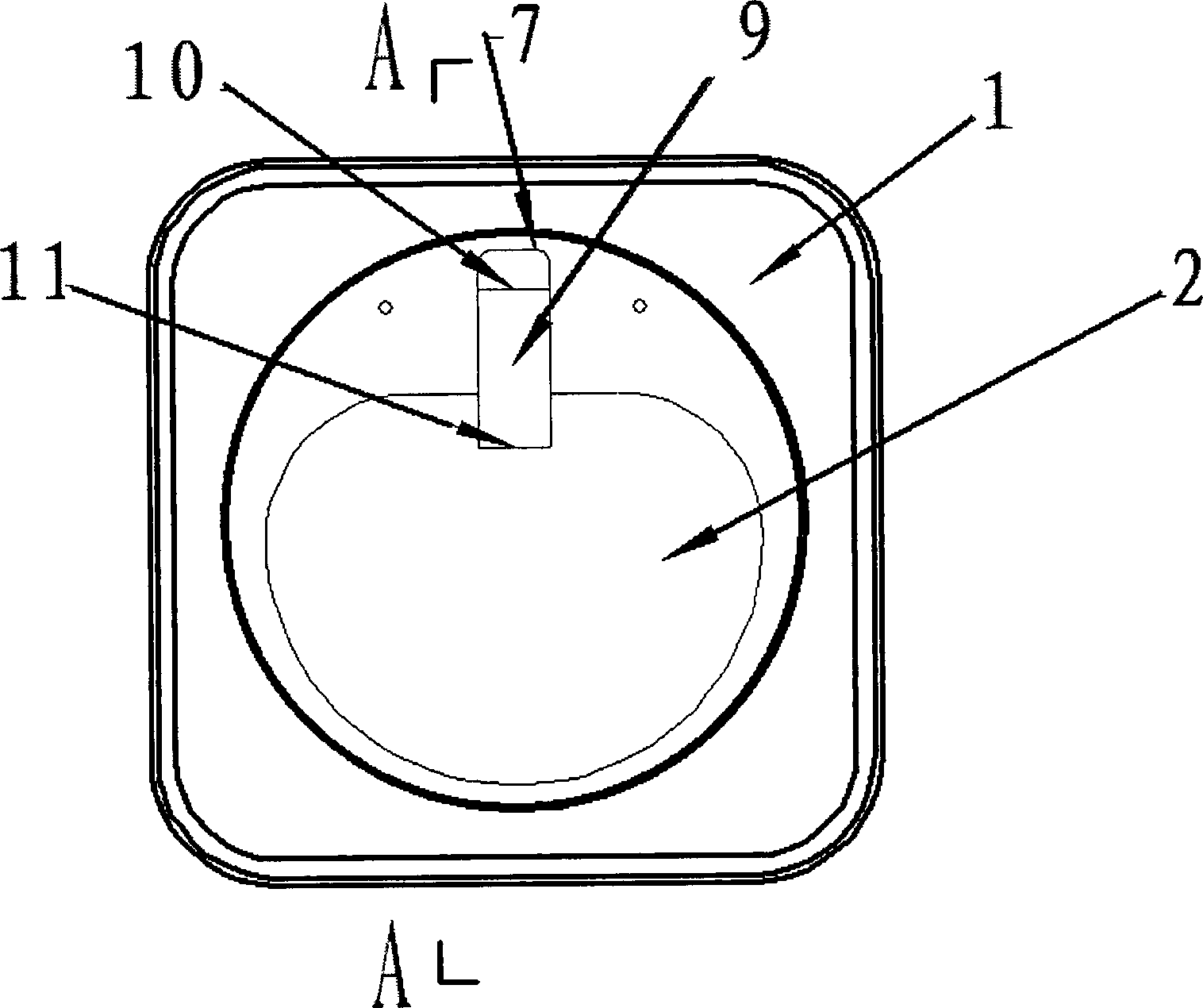

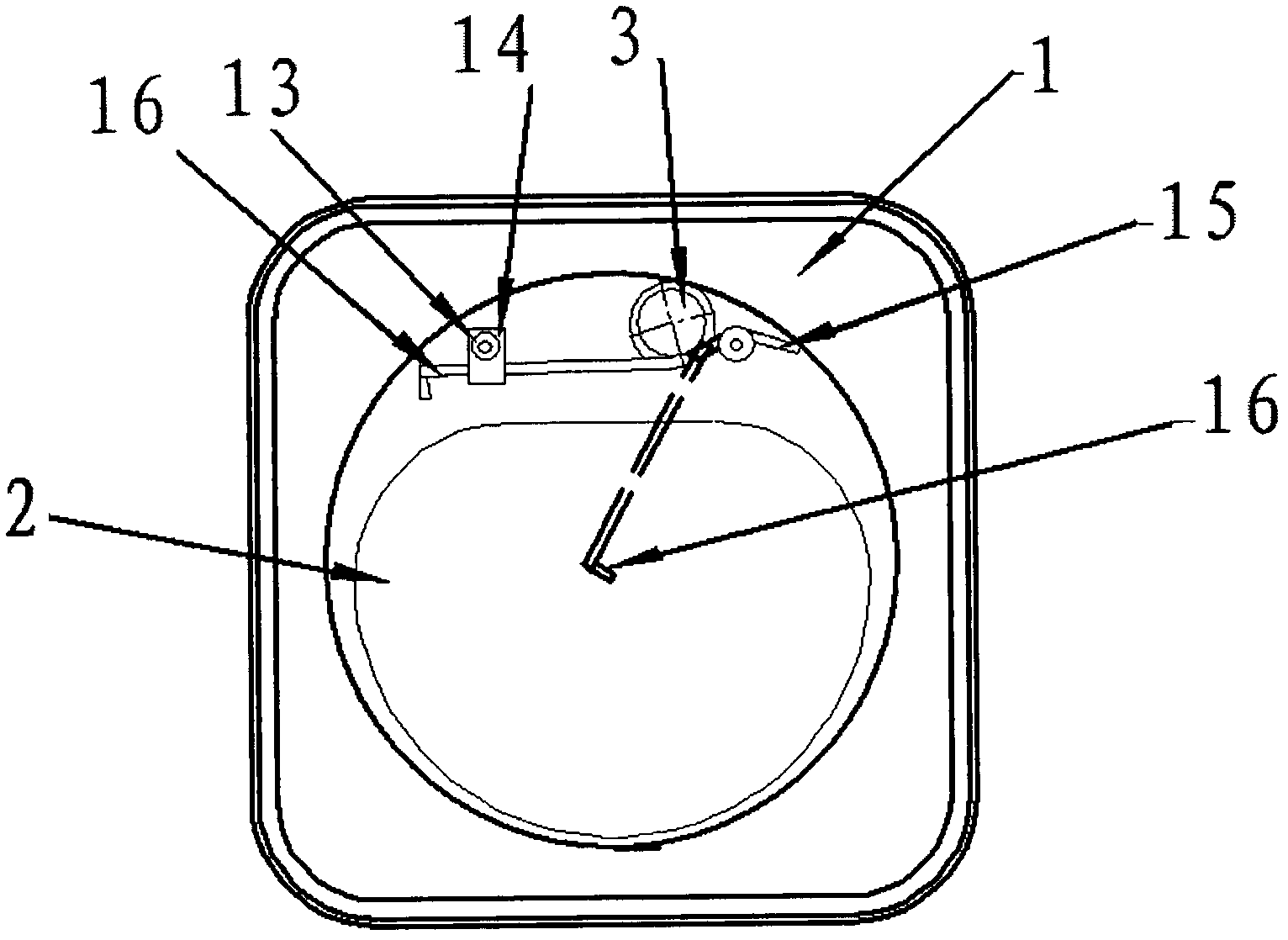

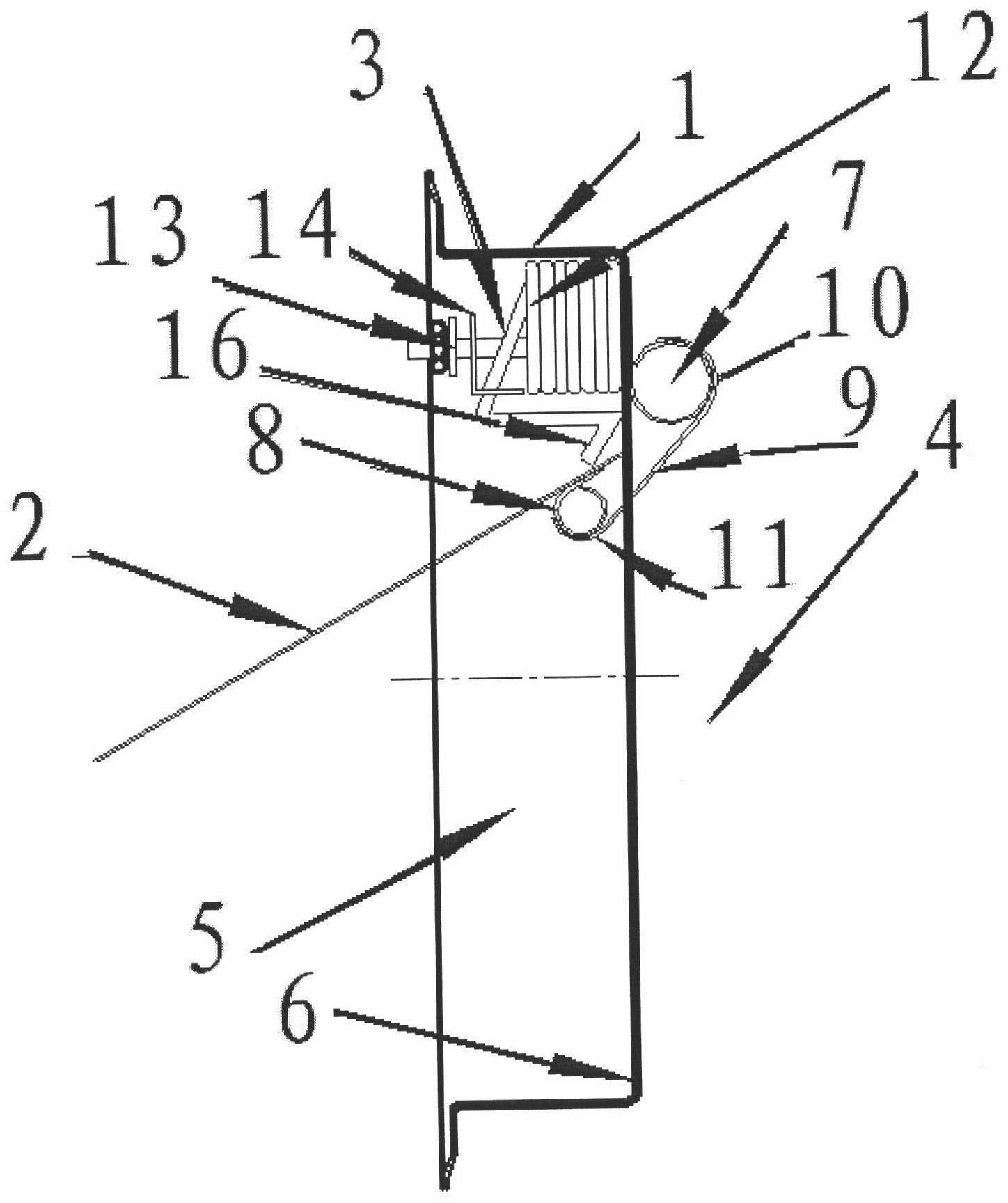

[0010] The technical solution of the present invention is an axial smoke exhaust and fire prevention check valve, which includes a valve body 1 , a valve plate 2 and an actuator 3 . The valve body 1 has a smoke inlet 4 and a smoke outlet 5, and a sealing ring 6 is arranged between the smoke inlet 4 and the smoke outlet 5, and the sealing ring 6 is perpendicular to the horizontal plane. Both the valve plate 2 and the actuator 3 are located on the side of the valve body sealing ring 6 at the smoke outlet 5 . The valve plate 1 is provided with two rotating shafts, an upper rotating shaft 7 and a lower rotating shaft 8 , and the upper rotating shaft 7 and the lower rotating shaft 8 are hingedly connected by a C-shaped connecting piece 9 . The upper rotating shaft 7 is located on the upper side of the valve plate 2 and is biased towards the side of the smoke inlet 4. It is rolled into a "6" shape and fixed on the valve body 1 with screws or spot welding. The axis of the upper rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com