Method for determining degradation and/or efficiency of laser modules and laser units

A laser and laser power technology, applied in lasers, laser devices, laser parts and other directions, can solve problems such as time-consuming, high cost, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

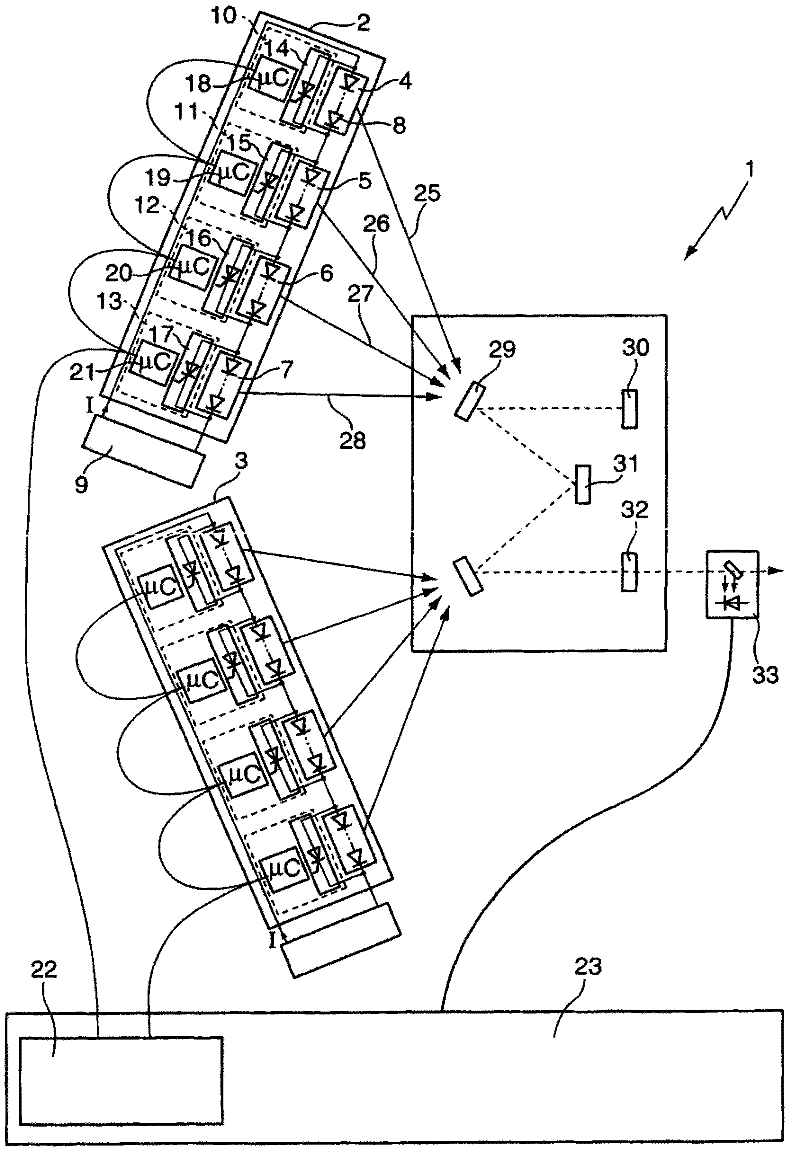

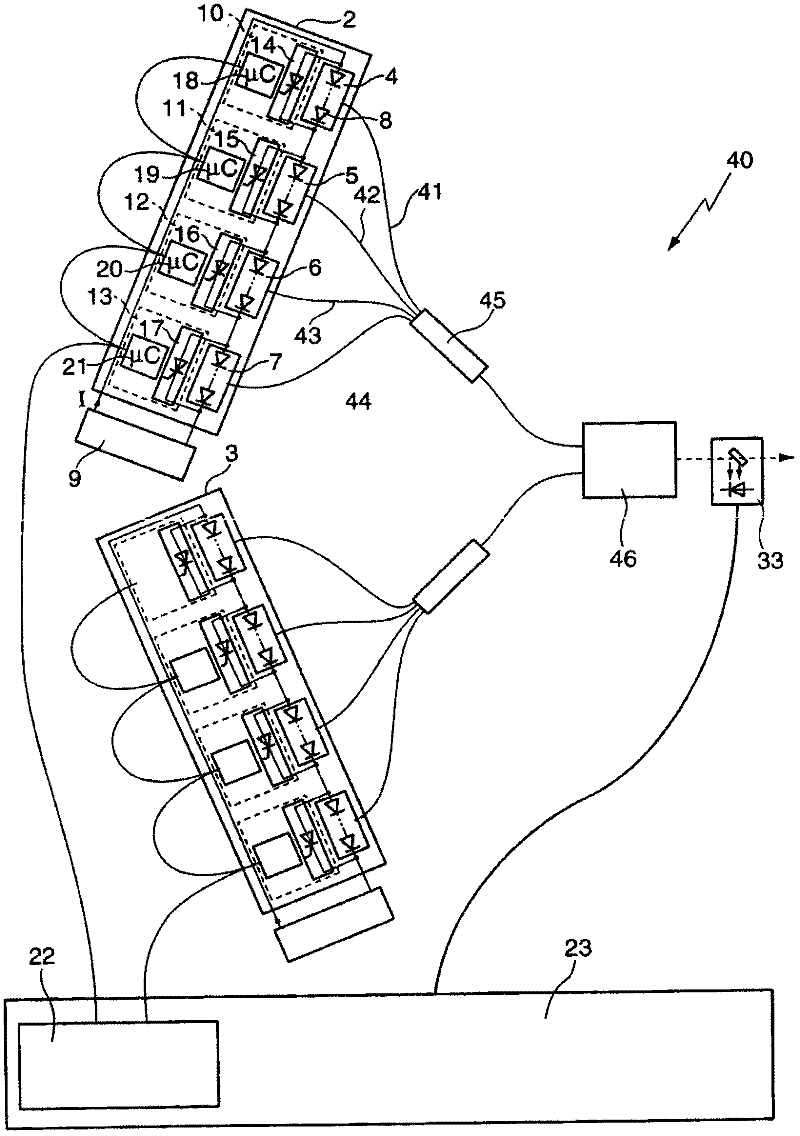

[0033] figure 1 A laser 1 is shown, wherein the laser 1 is designed as a disc laser and comprises two laser units 2 , 3 . The laser units 2 , 3 are constructed in the same manner, so that only the laser unit 2 will be described below.

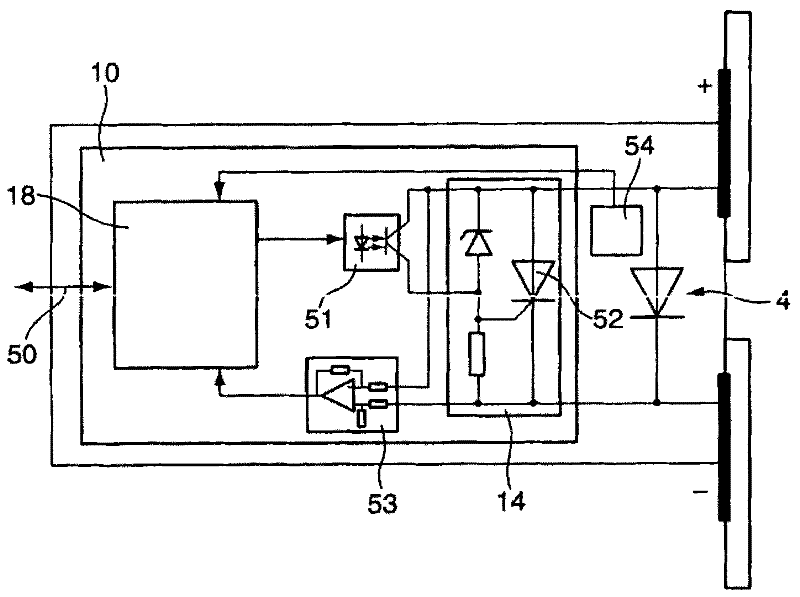

[0034] In this exemplary embodiment, the laser unit 2 has four laser modules 4 to 7 which are connected in series, each laser module 4 to 7 having one or more laser diodes 8 connected in series. The individual laser modules 4 to 7 are connected to a common power supply 9 so that the same current flows through all laser modules 4 to 7 . The voltage drop across the individual laser modules 4 to 7 can be different. A bypass structure 10 to 13 is associated with each laser module 4 to 7 , by means of which the relevant laser module 4 to 7 can be bypassed when the switching elements 14 to 17 are electrically conductively connected. Each bypass structure 10 to 13 has a microcontroller 18 to 21 . The microcontrollers 18 to 21 of the laser unit 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com