Tire bead coils

A technology of bead rings and disks, which is applied to tires, manufacturing rings from wires, and other household appliances. It can solve the problems of low work efficiency and high scrap rate, and achieve the goals of reducing scrap rate, improving work efficiency, and eliminating misoperation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

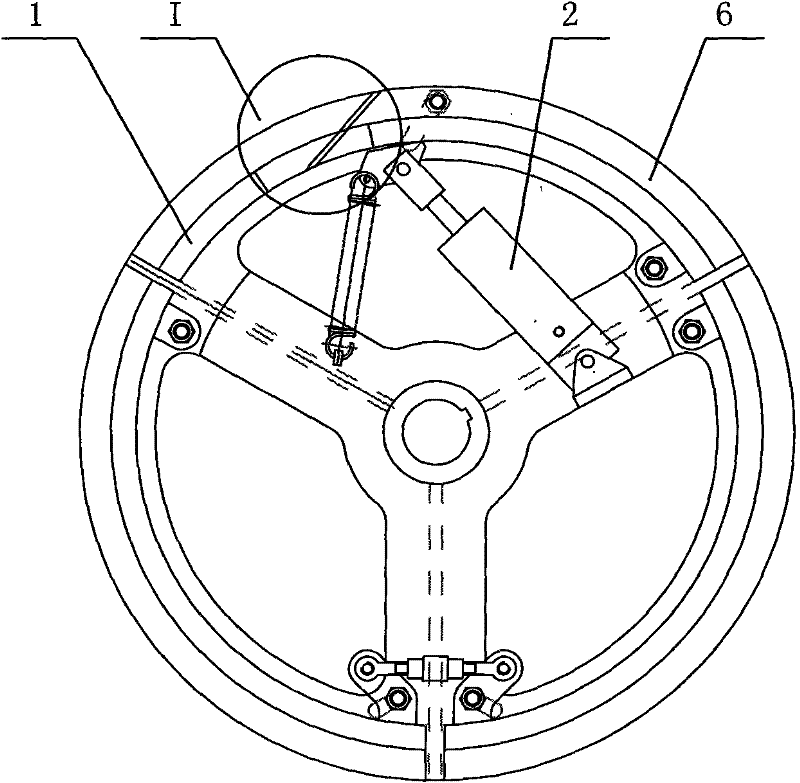

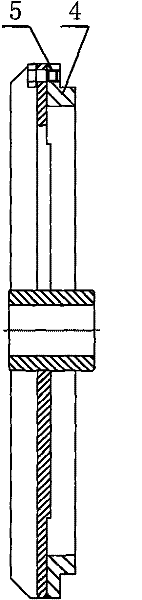

[0019] Such as figure 1 , 2 , 5 and 6, the present invention includes a fixed leaf 1 rolled into a disk and a movable leaf 6 rolled into a disk, and the fixed leaf 1 rolled into a disk and the movable leaf 6 rolled into a disk have a stepped cross section, wherein the lower end of the step is a winding disk 4. The upper end of the step is a flange 5, and the meshing opening 3 between the fixed vane 1 and the movable leaf 6 is a staggered joint, and the staggered joint refers to the staggered joint at the 3rd joint. The meshing surface of the blue disk 5 is different from the meshing surface of the winding disk 4 (that is, they are not on the same plane). The staggered distance L of the engaging openings 3 is 25-35 mm. Say 25, 27, 28, 30, 32, 34 or 35mm.

[0020] The working process of the present invention is as follows: start the cylinder 2, and the cylinder 2 drives the movable blade 5 of the coiled disc to move, so that the meshing port 3 is opened. The meshing surface ...

Embodiment 2

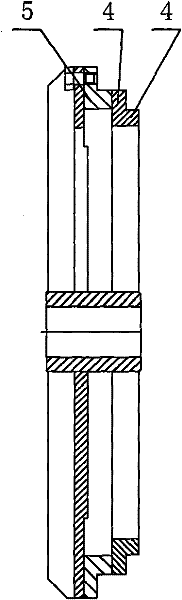

[0022] Such as Figure 7 As shown, there are two winding disks 4, and the meshing surfaces of two adjacent winding disks 4 are different from each other. In this embodiment, different winding disks 4 have different diameters, and travellers with different diameters can be wound, which is convenient and convenient to use. When winding, the lowermost winding disk 4 can be positioned by means of the side of the upper winding disk 4, and since the engaging surfaces of two adjacent winding disks 4 are not on the same plane, misoperation will not occur. Or three or four of the winding discs 4 . The staggered distance L between two adjacent surfaces at the meshing opening 3 is 25-35 mm. Say 25, 27, 28, 30, 32, 34 or 35mm.

[0023] In the above-mentioned embodiments, the engaging surface 3 is a zigzag engaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com