Polishing device

A polishing device and polishing sheet technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as large plant area and achieve the effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

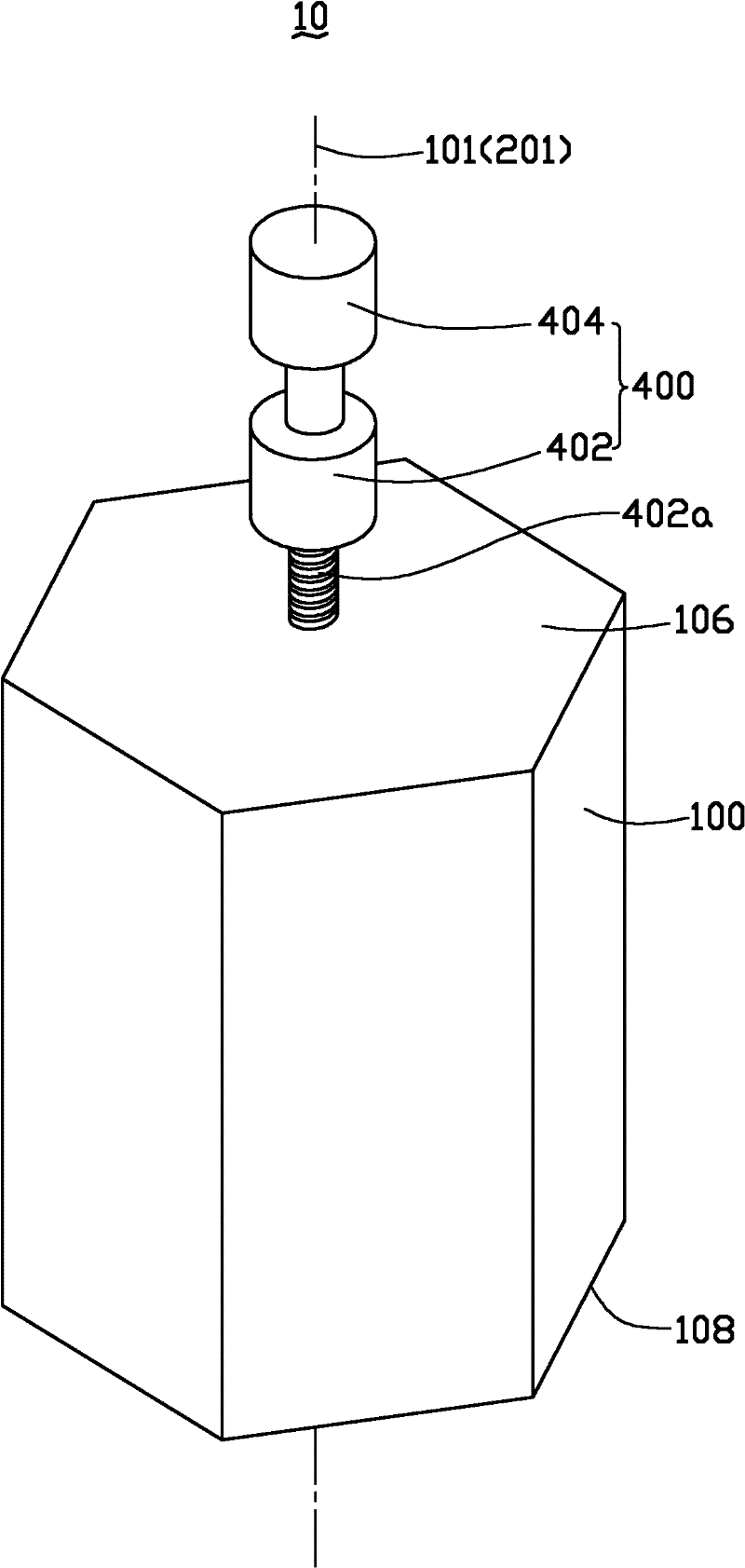

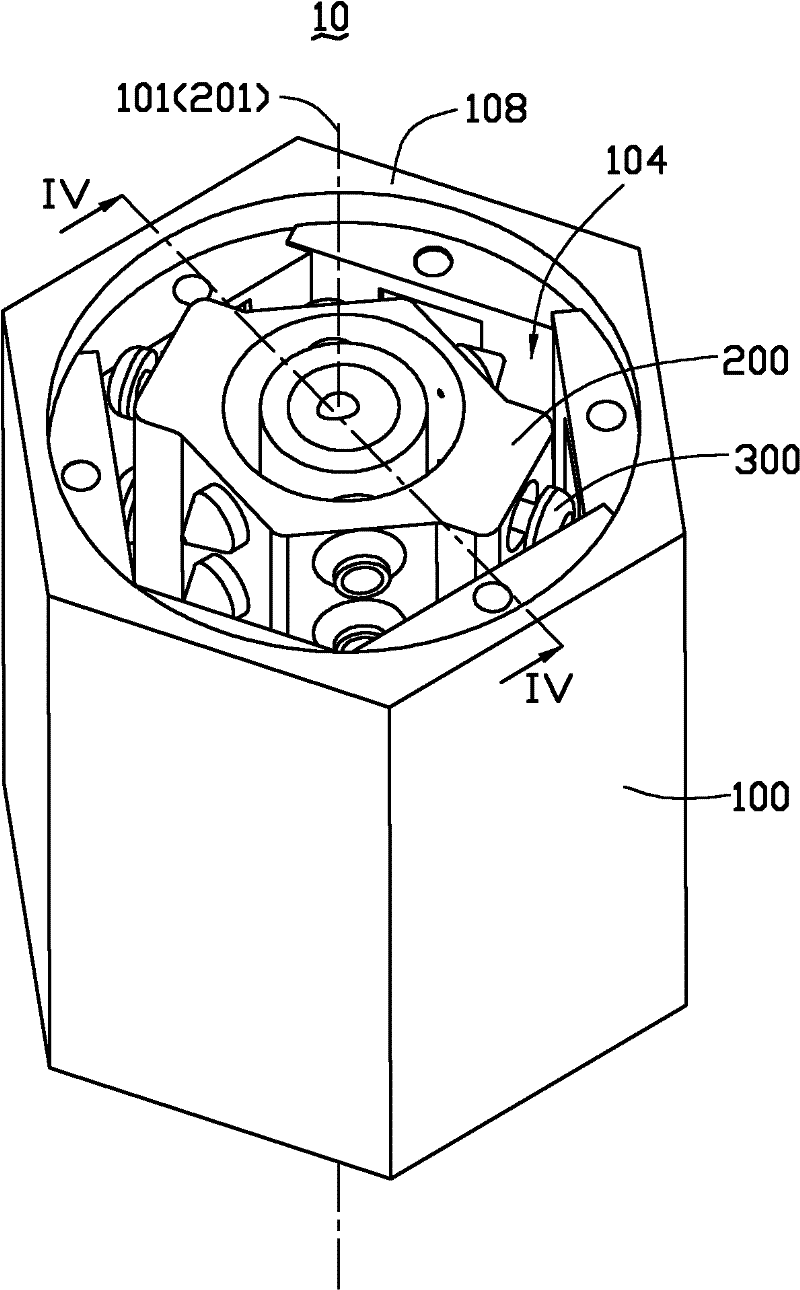

[0050] see figure 1 and figure 2 , The polishing device 10 according to the preferred embodiment of the present invention includes an outer cylinder 100 , an inner cylinder 200 , a plurality of polishing mechanisms 300 and an actuator 400 .

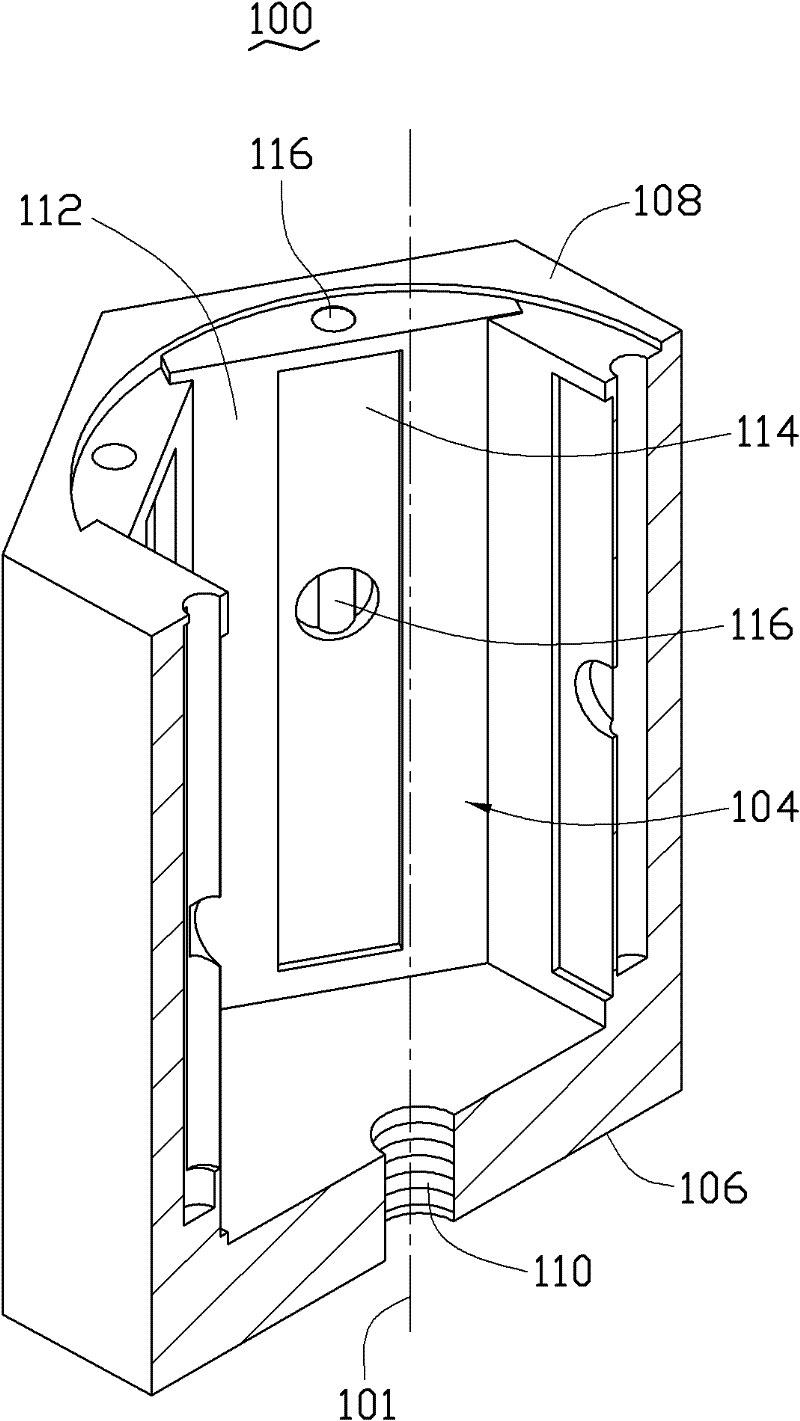

[0051] Please refer to figure 1 , the outer cylinder 100 includes a top plate 106 and a bottom plate 108 facing away from each other. Please refer to image 3 , the center of the top plate 106 is provided with a screw hole 110 penetrating through the top plate 106 . The screw hole 110 is located on the central axis 101 of the outer cylinder 100 . The outer cylinder 100 defines a cavity 104 formed in the outer cylinder 100 from the bottom plate 108 toward the top plate 106 . The cavity 104 is in the shape of a regular hexagonal column formed by connecting six inner surfaces 112 sequentially. Each inner surface 112 is provided with a fixing groove 114 for fixing the workpiece to be polished. Each fixing slot 114 defines an air suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com