A squeegee for screen printing of solar cells

A solar cell and screen printing technology, which is applied in the field of solar photovoltaics, can solve problems such as affecting the quality of solar cell screen printing, reducing the quality of cell printing, and cell debris, so as to save the amount of paste, improve quality and effect, the effect of not easy to print fragments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

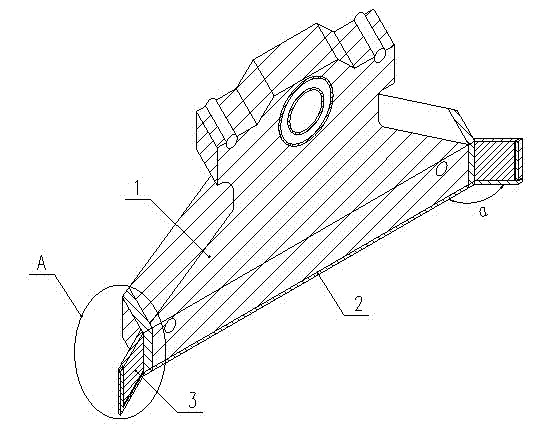

[0015] The scraper used for screen printing of solar cells according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

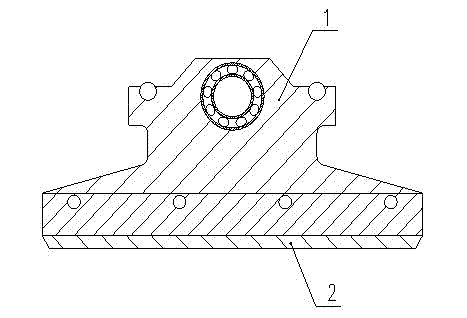

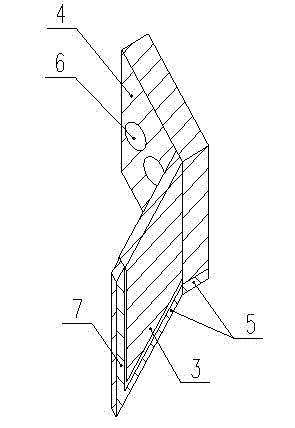

[0016] see figure 2 , image 3 As shown, a scraper used for screen printing of a solar battery sheet according to the present invention is provided with a scraper 2 at the lower end of the cutter body 1, and auxiliary scrapers 3 are respectively arranged on both sides of the cutter body 1, and the auxiliary scraper The plate 3 is made of stainless steel, the angle α between the auxiliary scraper 3 and the front of the cutter body 1 is between 110° and 130°, the lower end of the auxiliary scraper 3 is provided with an auxiliary scraper 5, and the auxiliary scraper 5 The lower plane is equal to the lower plane of the scraper 2 , and a side scraper 7 is also arranged on the outer side of the auxiliary scraper 3 . In the present invention, an installation structure of the auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com