A kind of aircraft double-layer air-liquid skin heat exchange method

A technology of heat exchanger and fuselage skin, which is applied in the field of improvement of aircraft air-liquid heat exchange mode, can solve the problem of heat exchange capacity, poor cooling effect, large volume of air-liquid heat exchanger, and large fuel compensation of aircraft Loss and other problems, to meet the requirements of stealth performance, large heat exchange, and improve the effect of flight time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail through specific embodiments below.

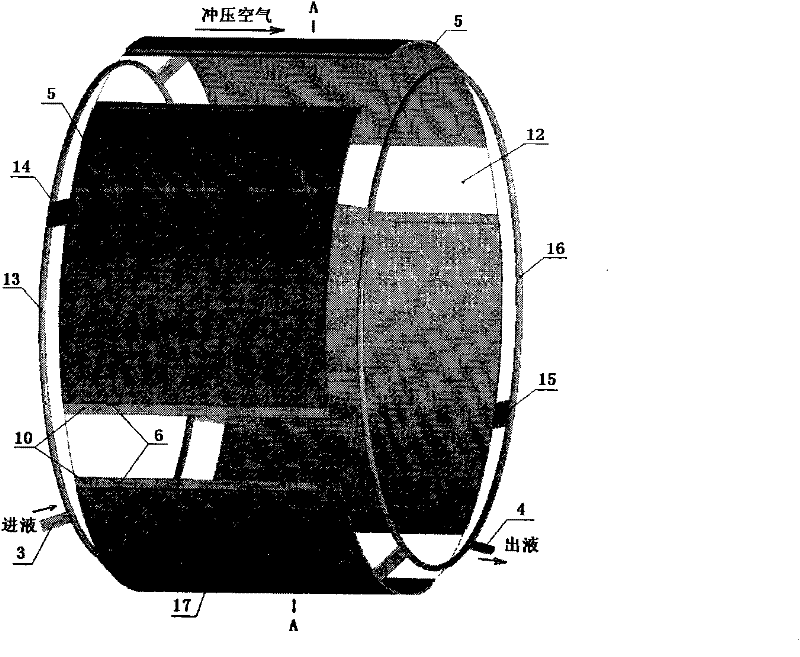

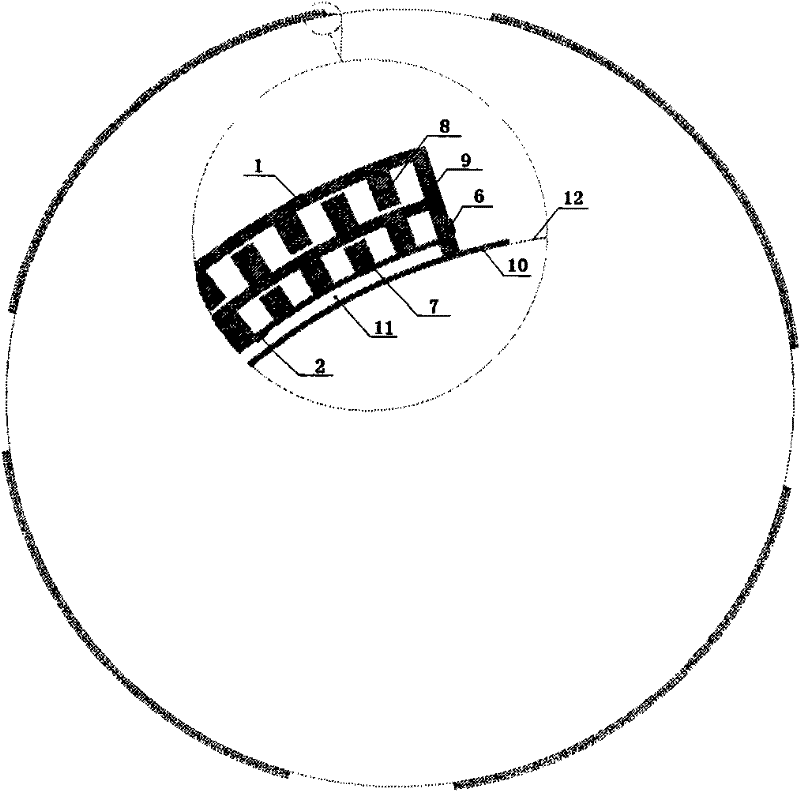

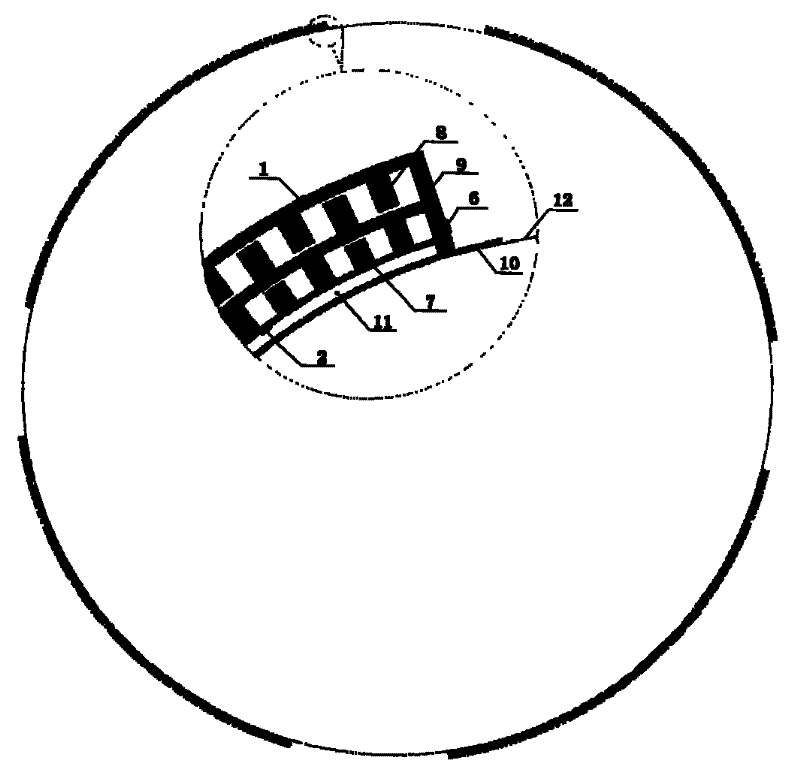

[0037] The invention adopts the boundary layer heat dissipation technology integrated with the aircraft skin, and designs a double-layer air-liquid skin heat exchanger installed on the outer surface of the aircraft skin. The inside of the skin heat exchanger is a thermal fluid (65 coolant), the outer surface of the heat exchanger uses the relative velocity between the aircraft and the ambient air to cool the outer heat fluid; in addition, the inner surface of the heat exchanger and the outer surface of the aircraft skin form a gap of 5-10 mm, and the aircraft and the air are used again. The relative velocity of the ambient air cools the inner thermal fluid.

[0038] Workflow: The hot fluid (No. 65 coolant) coming out of the electronic equipment enters the "liquid inlet distribution main pipe [13]" through the "liquid inlet [3]", and then enters the independent fluid inlet pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap