an engine connecting rod

A technology of engine connecting rod and connecting rod body, which is applied to connecting rods, mechanical equipment, shafts and bearings, etc. It can solve the problems of weak fixing, easy wear and deviation, and achieve the effect of rich structural changes and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

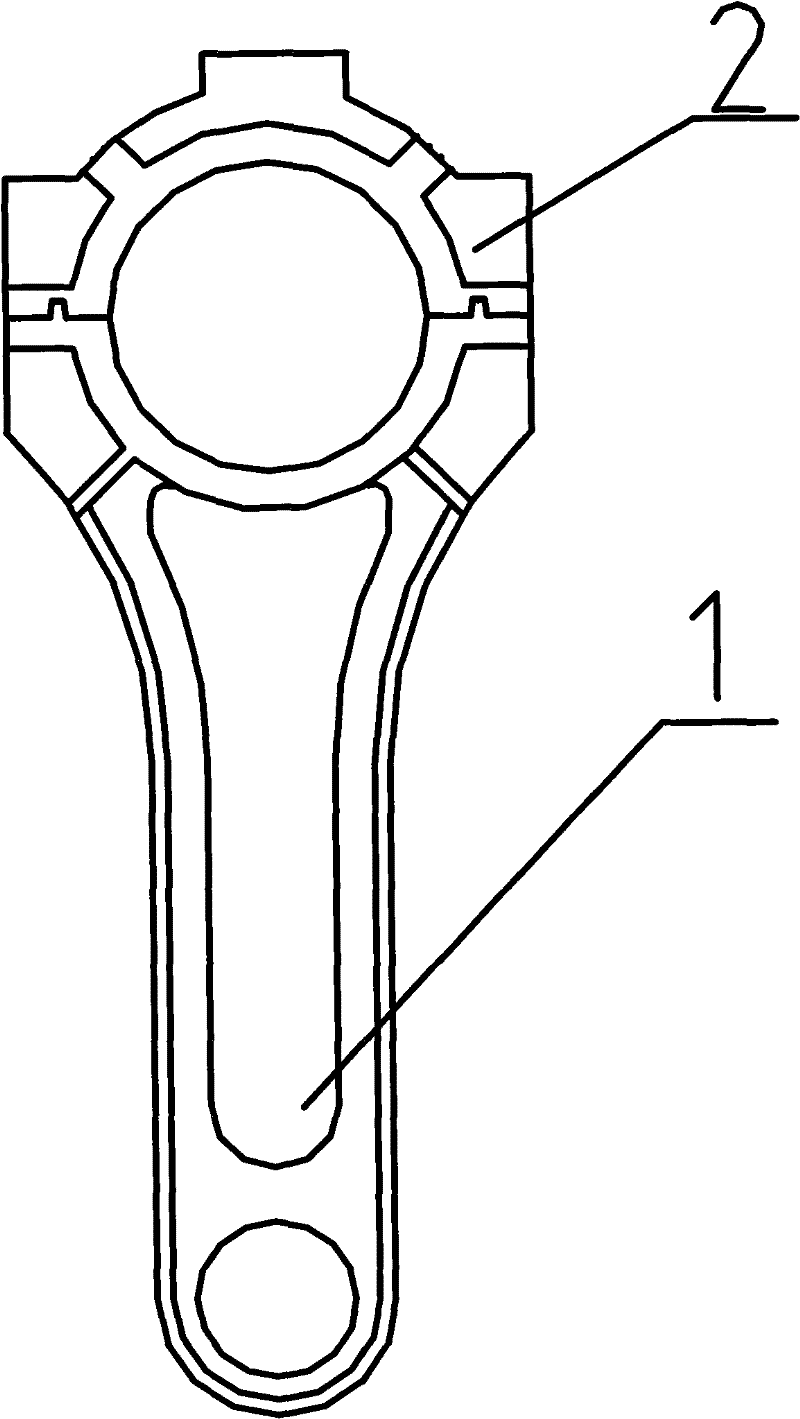

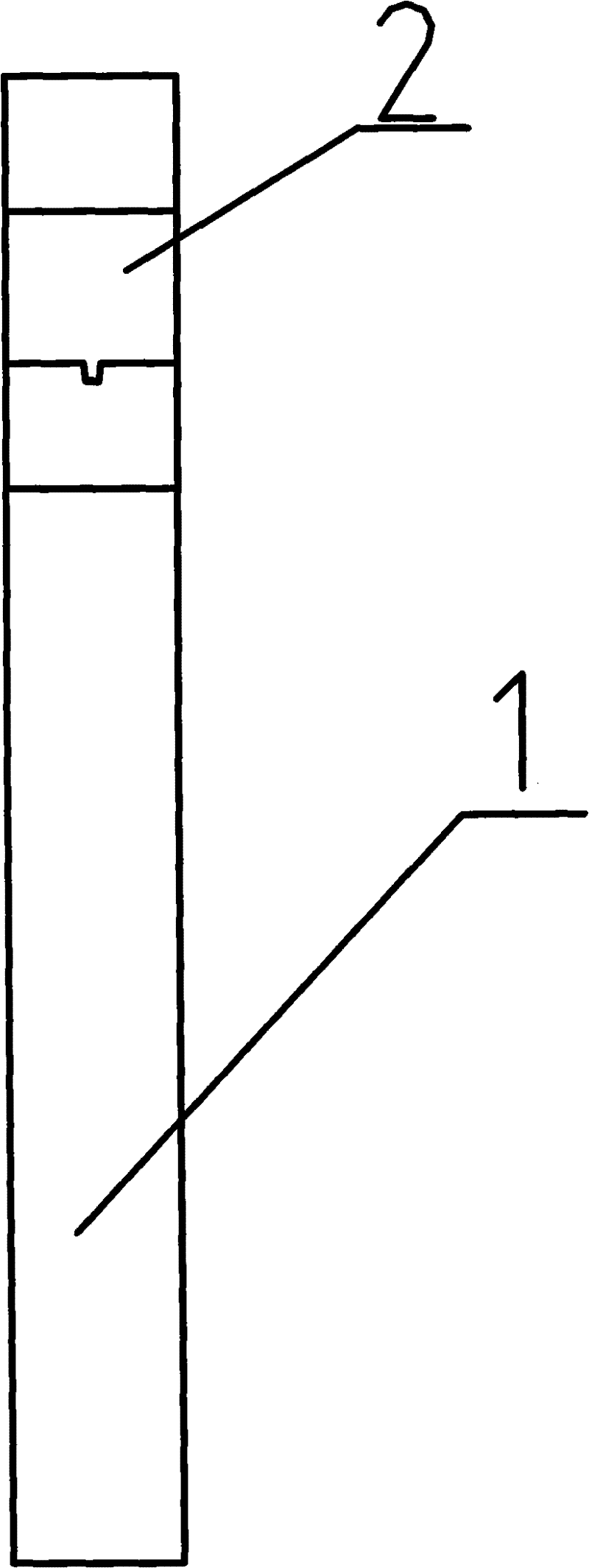

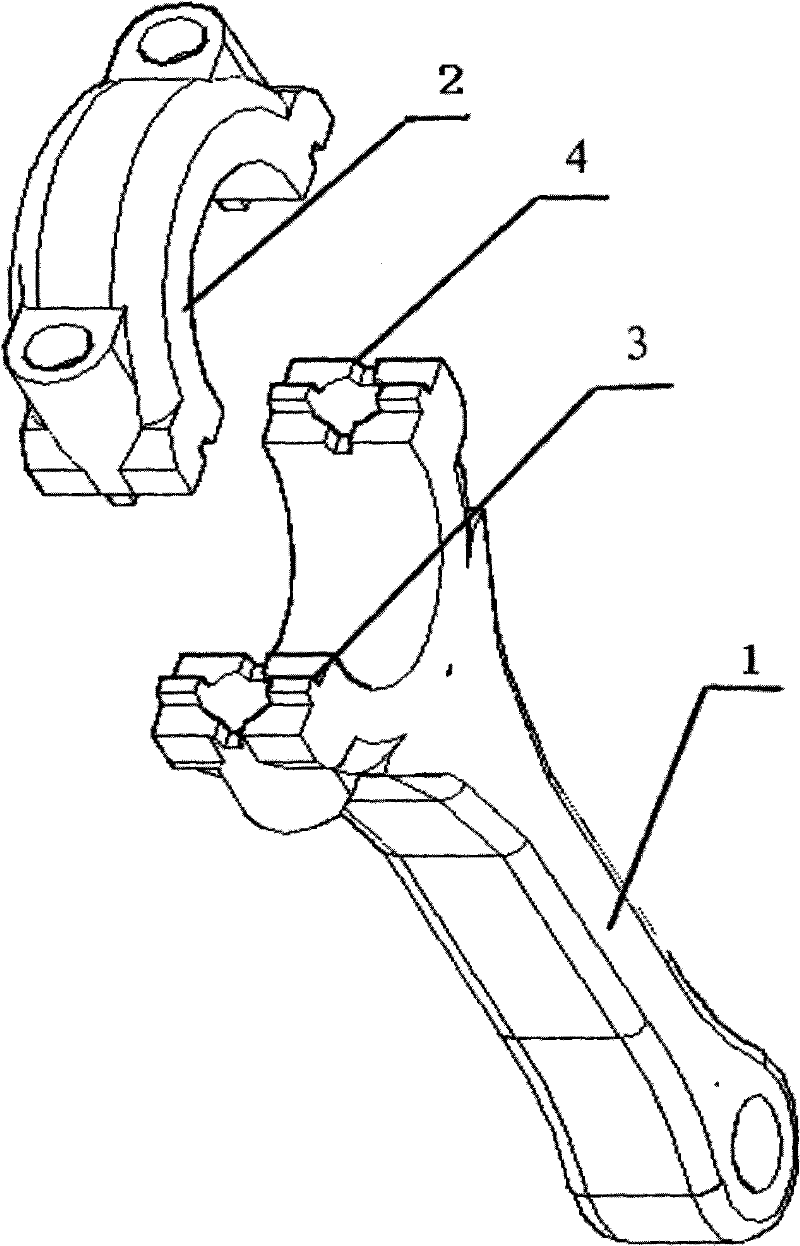

[0020] combine figure 1 , figure 2 , image 3 and Figure 4 , an engine connecting rod, comprising a connecting rod body 1 and a connecting rod cover 2, bolts are used between the connecting rod body 1 and the connecting rod cover 2, and the mating surface of the connecting rod body 1 and the connecting rod cover 2 is set There are intersecting and corresponding convex teeth 3 and grooves 4, and the connecting rod body 1 and the connecting rod cover 2 are connected by crossing and corresponding convex teeth 3 and grooves 4; the convex teeth 3 and grooves 4 form a cross shape; the connecting rod body 1 and the connecting rod cover 2 are meshed and connected by cross-shaped convex teeth 3 and grooves 4, and then fixed by bolts, so that all directions between the mating surfaces can be Fixed by intersecting convex teeth 3 and grooves 4, there will be no sliding of the connecting rod body 1 and the connecting rod cover 2 in the plane direction of the mating surface, avoiding t...

Embodiment approach 2

[0022] combine Figure 5 , the intersecting protruding teeth 3 and grooves 4 on the mating surfaces of the connecting rod body 1 and the connecting rod cover 2 can be multiple; Figure 5 There are multiple convex teeth 3 and grooves 4 shown, and the connecting rod body 1 and the connecting rod cover 2 are meshed and connected by multiple convex teeth 3 and grooves 4, and then fixed by bolts so that the mating surface is in the plane direction All directions above can also be fixed by the protruding teeth 3 and grooves 4, so that the sliding of the connecting rod body 1 and the connecting rod cover 2 in the plane direction of the mating surface will not occur, and the contact between the connecting rod body 1 and the connecting rod cover 2 will not be avoided. The relative motion ensures the motion accuracy with the crankshaft, and further improves the reliability, durability and safety of the engine connecting rod; the meshing connection of multiple convex teeth 3 and grooves ...

Embodiment approach 3

[0024] combine Figure 6 , the protruding teeth 3 and grooves 4 on the connecting rod body 1 and the connecting rod cover 2 are mutually intersecting, Figure 6 What is shown is that the protruding teeth 3 and the grooves 4 are intersected with each other; the connecting rod body 1 and the connecting rod cover 2 are meshed and connected by the protruding teeth 3 and the grooves 4 intersecting each other, and then fixed by bolts so that they fit together All directions between the surfaces can be fixed by intersecting protruding teeth 3 and grooves 4, so that there will be no sliding of the connecting rod body 1 and the connecting rod cover 2 in the plane direction of the mating surface, and avoiding the connection between the connecting rod body 1 and the connecting rod cover 2. The relative movement of the connecting rod cover 2 ensures the movement accuracy with the crankshaft, and further improves the reliability, durability and safety of the engine connecting rod; the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com