Material testing system and method

A material testing and material testing machine technology, applied in the direction of analyzing materials, using stable bending force to test material strength, measuring devices, etc., can solve the problems that cannot meet the accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

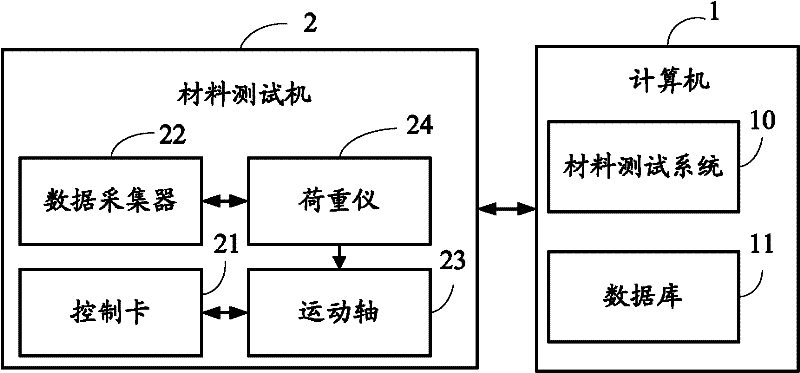

[0014] Such as figure 1 Shown is a schematic diagram of the operating environment of a preferred embodiment of the material testing system of the present invention. The material testing system 10 runs on a computer 1 connected to a material testing machine 2 . The material testing machine 2 includes a control card 21 , a data collector 22 , a motion axis 23 and a load meter 24 . The control card 21 controls the movement of the movement shaft 23, and the load meter 24 is installed on the movement shaft 23, that is, the load meter 24 and the movement shaft 23 move together. The data collector 22 is connected to the load meter 24 for collecting the data measured by the load meter 24 . In this embodiment, the measured data includes: the load value and the displacement value of the load cell 24 and so on. The data collector 22 is also used to send the collected data to the computer 1, the computer 1 includes a database 11, the database 11 is used to store the data sent by the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com