Device and method for automatically controlling temperature of aluminium piston casting die in on-line manner

An automatic control device and casting mold technology, which is applied in the direction of using electric methods for temperature control, etc., can solve the problems of low casting rejection rate and many influencing factors of aluminum piston castings, and achieve high casting production efficiency and low casting rejection rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below through specific examples. It should be noted that the following descriptions are only for explaining the present invention, and do not limit its content.

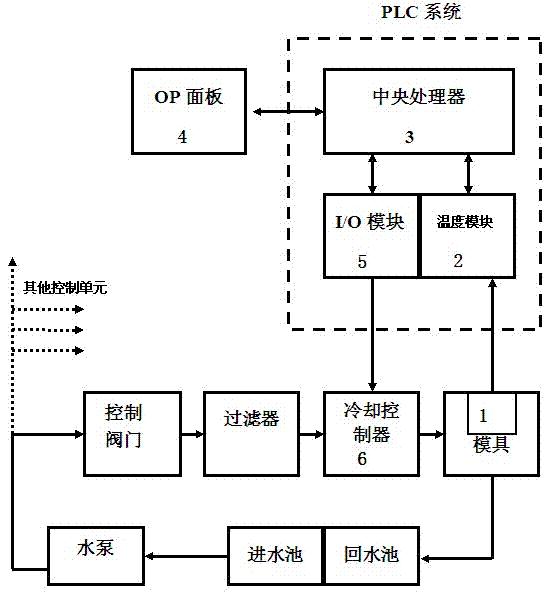

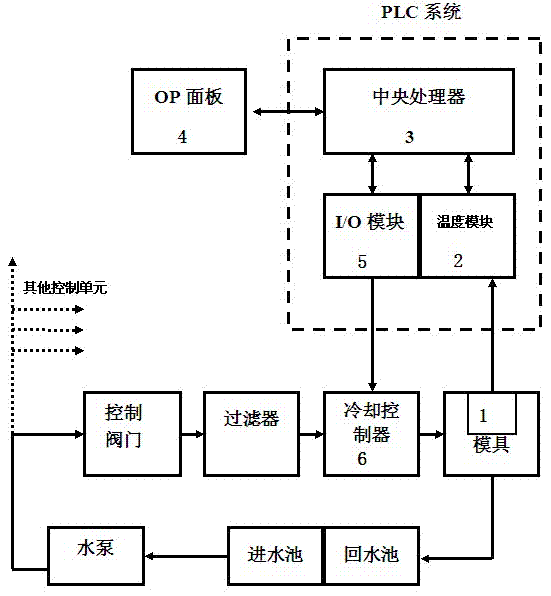

[0020] figure 1 Shown is the control schematic diagram of the online automatic temperature control device for the aluminum piston casting mold. The temperature sensor 1 arranged in the casting mold of the aluminum piston is connected to each other, and the I / O module 5 is connected to the cooling controller 6 installed on the cooling water inlet pipeline before the casting mold of the aluminum piston. figure 1 The central processing unit 3, the temperature module 2 and the I / O module 5 are included in the dotted line, and they together form a PLC system.

[0021] The model of central processing unit 3 is C200HE CPU; the model of OP panel 4 is MPT002; the temperature module 2 adopts TS01 temperature module.

[0022] The cooling controller 6 adopts the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com