Motor liquid cooling structure

A liquid-cooled structure and motor shaft technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of slow heat dissipation, difficult heat, motor aging, etc., to achieve rapid heat dissipation and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

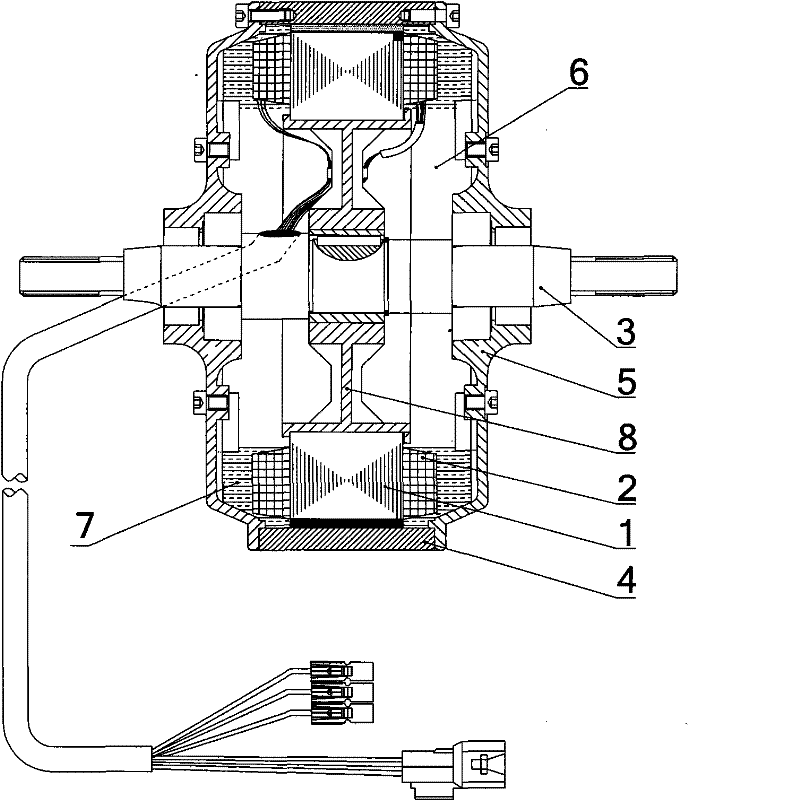

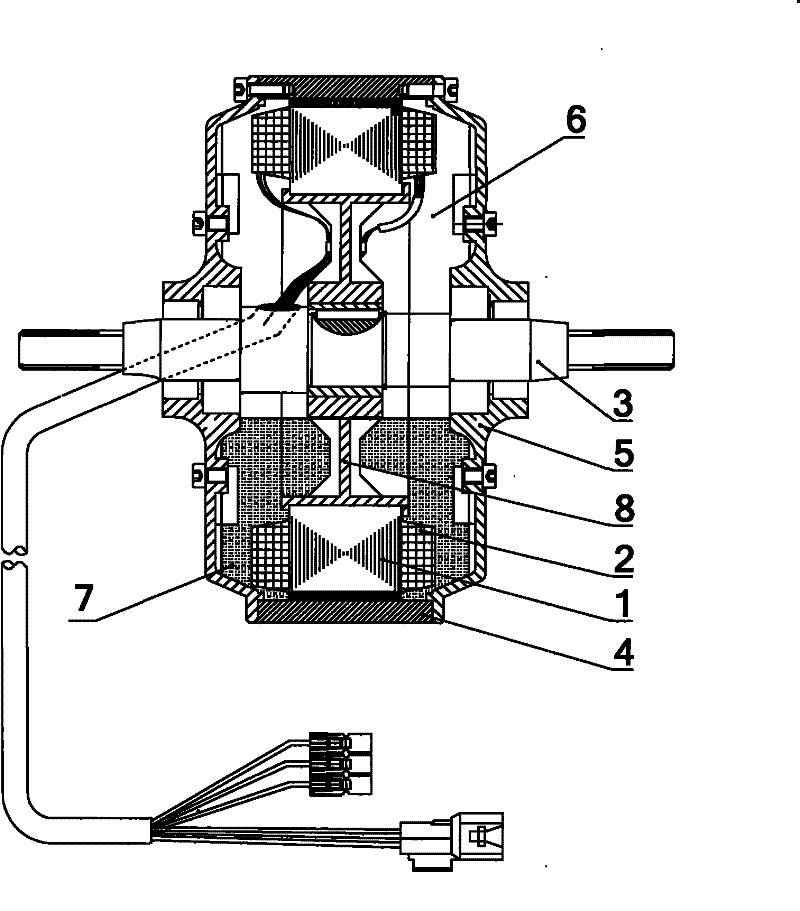

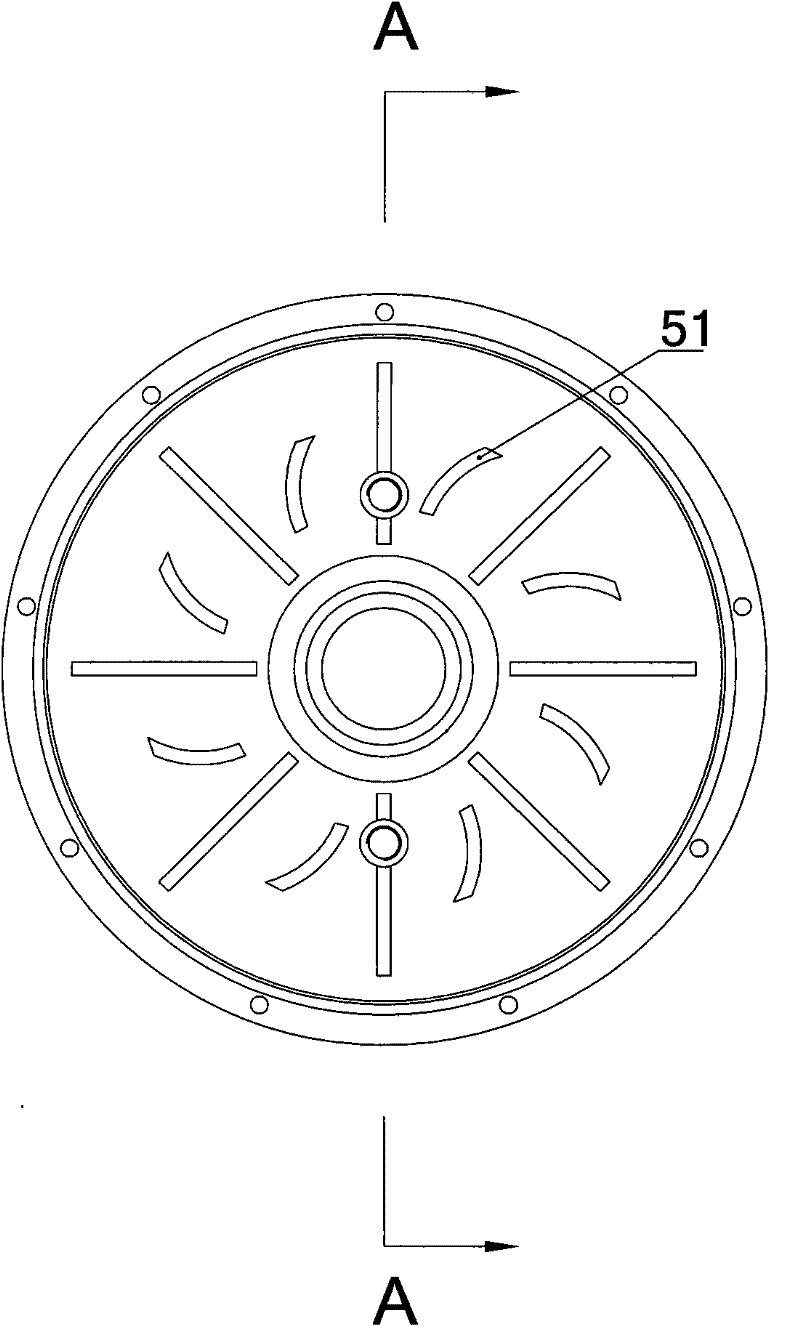

[0018] Embodiment: a motor liquid cooling structure, the outer side of the stator core 1 of the motor is wound with a winding 2, the stator core 1 wound with the winding 2 is fixed on the motor shaft 3 through a bracket 8, and the motor casing 4 is axially two The end seal is fixed with an end cover 5, and the integral dynamic seal formed by the end cover 5 and the casing 4 is sleeved on the outside of the stator core 1 wrapped with the winding 2. The casing 4, the end cover 5, the motor shaft 3 and the A sealed annular space 6 is formed between the stator cores 1 wrapped with windings 2, and a cooling liquid 7 is provided. The cooling liquid 7 is contained in the annular space 6. Under the combined action of the rotation of the cover 5, the agitation of the ribs 51 inside the end cover and the centrifugal force, the cooling liquid 7 moves in the sealed annular space. When the cooling liquid 7 flows through the winding 2 and the surface of the stator core 1, the winding 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com