Automatic paper feeding scanning device

A technology of automatic paper feeding device and scanning device, which is applied in the direction of image communication, electrical components, etc., can solve the problems of degumming, shortening the service life of automatic paper feeding scanning device, and the inability of the scanning module 3 to move smoothly to the bottom of the document platform 11, etc., to achieve Prevent impact, ensure service life, and ensure the effect of scanning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

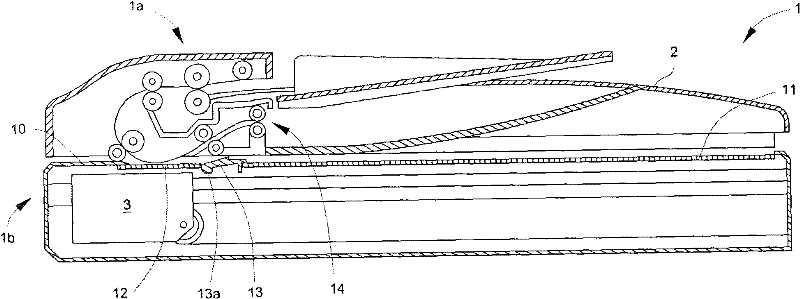

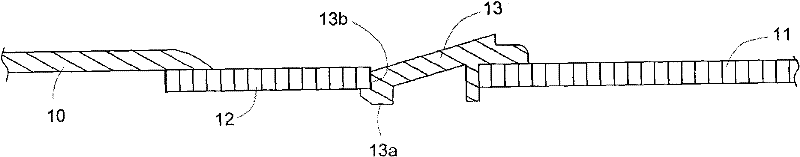

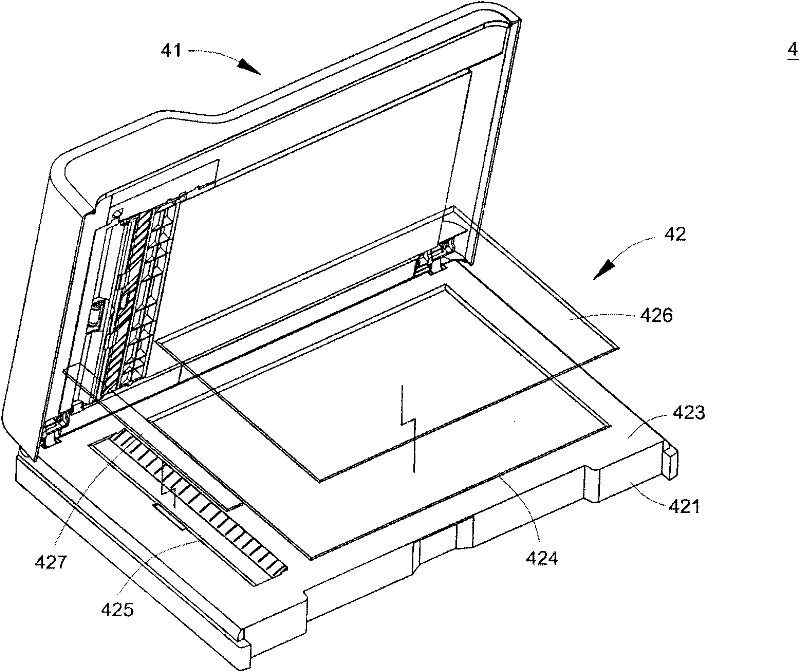

[0028] The present invention proposes an automatic paper-feed scanning device, which solves the problems caused by the prior art by changing the combination of the second light-transmitting plate and the second scanning window for paper-feed scanning. see image 3 and Figure 4 , image 3 It is a partially decomposed three-dimensional structural schematic diagram of the first preferred embodiment of the automatic paper-feeding scanning device of the present invention, Figure 4 It is a front sectional schematic diagram of the first preferred embodiment of the automatic paper feeding scanning device of the present invention. In addition, in order to clearly express the paper feeding path, Figure 4 and Figure 5 The drawing of the paper feed roller will be omitted in .

[0029] Please refer to image 3 and Figure 4 , the automatic paper feeding scanning device 4 includes an automatic paper feeding device 41 and a flatbed scanner 42 disposed below the automatic paper fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com