Consumable-free self-connection construction method for light steel keels

A construction method and light steel keel technology, applied in the field of building decoration and decoration, can solve the problems of low construction efficiency, poor construction site environment, large consumption of auxiliary materials, etc., and achieve high construction efficiency and no construction noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

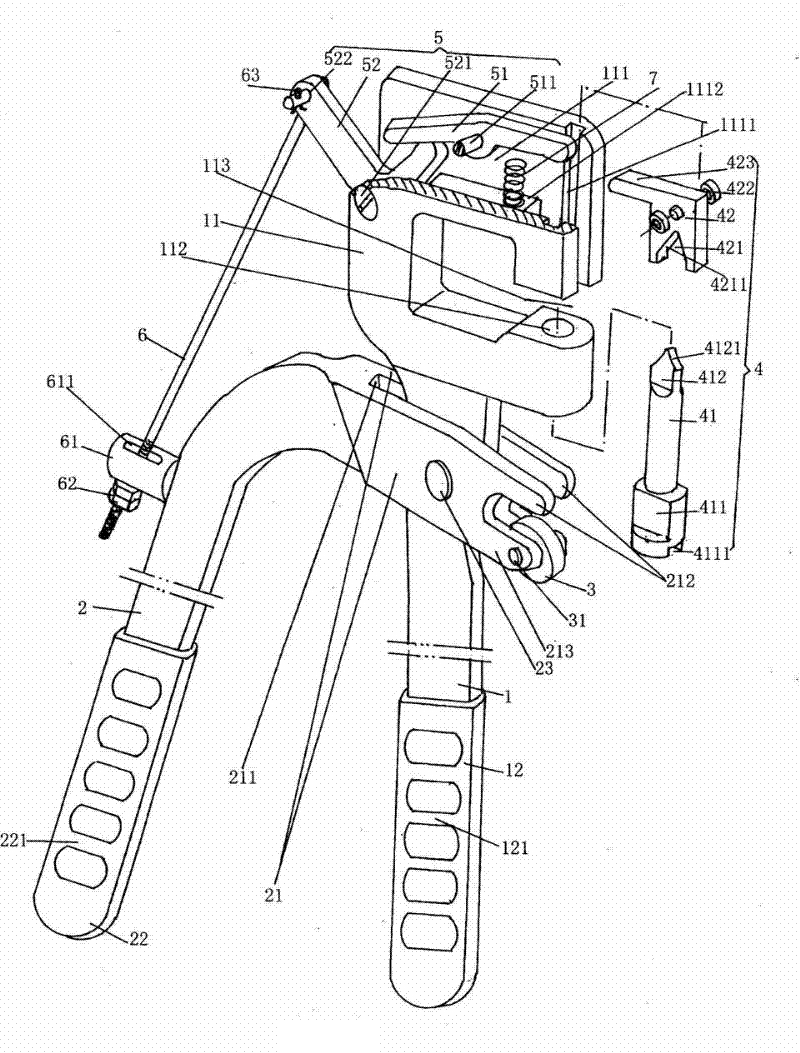

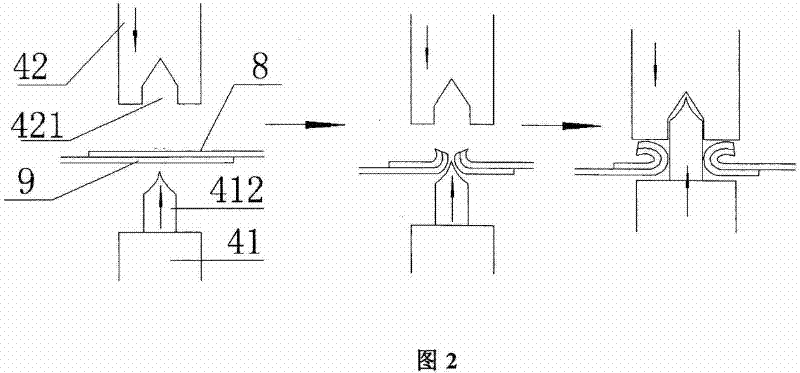

[0034] Please see figure 1 with figure 2 .

[0035] A) Equipped with a handheld riveting pliers, the specific structure of the handheld riveting pliers figure 1 Reveal, see figure 1 , A first handle 1 is given. Considering the comfort when gripping in use, a non-metallic first sheath 12 is added to the lower part of the first handle 1, which is preferably not limited to The material of the first sheath 12 is plastic or nylon or rubber. In this embodiment, plastic is selected, and a first non-slip flange 121 is also formed on the surface of the first sheath 12; the upper part of the first handle 1 is formed as a clamp The pliers head 11 is provided with a pliers head slot 111, which can also be called a pliers head cavity; the middle part of the first handle 1 is hinged with the second handle 2 which will be described in detail below Connected. At present figure 1 The position state shown is an example (the same below). A guide pulley groove 1111 is provided on a pair of gr...

Embodiment 2

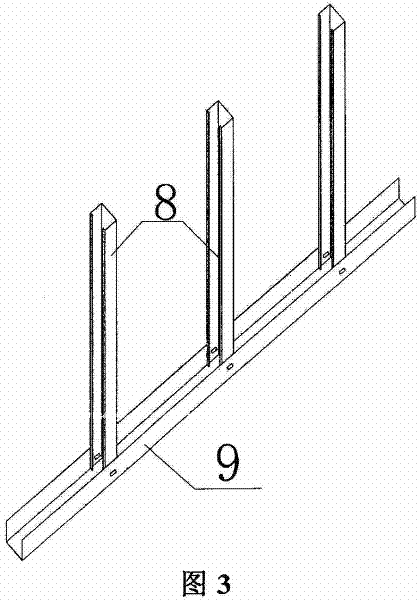

[0043] Please see image 3 .

[0044] In step B), the vertical keel is used as the first keel 8 and the ground keel is used as the second keel 9, and the end of the first keel 8 is overlapped with the second keel 9. The rest are the same as the description of Embodiment 1.

Embodiment 3

[0046] Please see Figure 4 .

[0047] In step B), the two vertical keels that need to be connected are used as the first keel 8, the connecting keel for connecting the two vertical keels is used as the second keel 9, and one end (upper end) of the second keel 9 is connected to The upper first keel 8 of the two first keels 8 overlaps, and the other end (lower end) of the second keel 9 is overlapped with the lower first keel 8 of the two first keels 8. The rest are the same as the description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com