Polyurethane molding closing perfusion foaming mold base

A foaming mold and polyurethane technology, which is applied in the field of polyurethane molding foaming equipment, can solve the problems of troublesome manual operation of observation samples of maintenance machines, reduction of human operation space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]

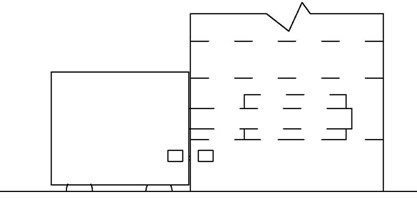

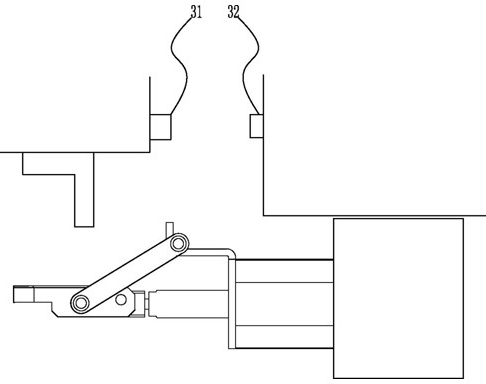

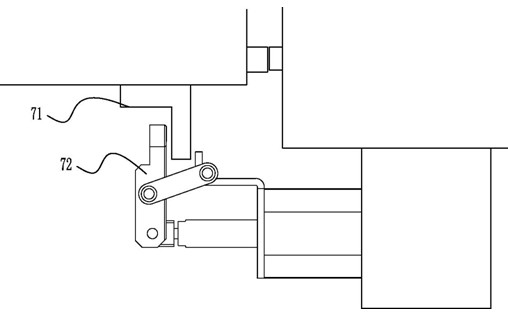

[0028] like figure 1 , 2 As shown, a polyurethane molding closed-mold perfusion foaming mold base is characterized in that: it includes the first split body 2 of the mold base and the second split body of the mold base, and the first split body 2 of the mold base includes Lower mold base, upper mold base, clamping mechanism, master cylinder and patrix 39, patrix 39 are fixedly connected on the upper mold base, lower mold base is positioned at upper mold 39 just below, set between lower mold base and upper mold 39 There is a height space corresponding to the lower mold 5;

[0029] The second split body of the formwork includes a ground walking trolley 6 and a lower mold 5. The front end of the ground walking trolley 6 is provided with left and right clamps 4, and the lower mold 5 is arranged between the left and right clamps 4. The lower mold 5 The edge is consistent with the height position of the upper edge 38 of the lower mold base;

[0030] The first split body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com