Oil nozzle assembly of diesel engine

A technology for fuel injectors and diesel engines, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc. It can solve the problems of increased opening resistance, slow opening response, and increased high-pressure fuel loss of the needle valve of the fuel injector to achieve improved closing Response speed, response speed improvement, and the effect of optimizing structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

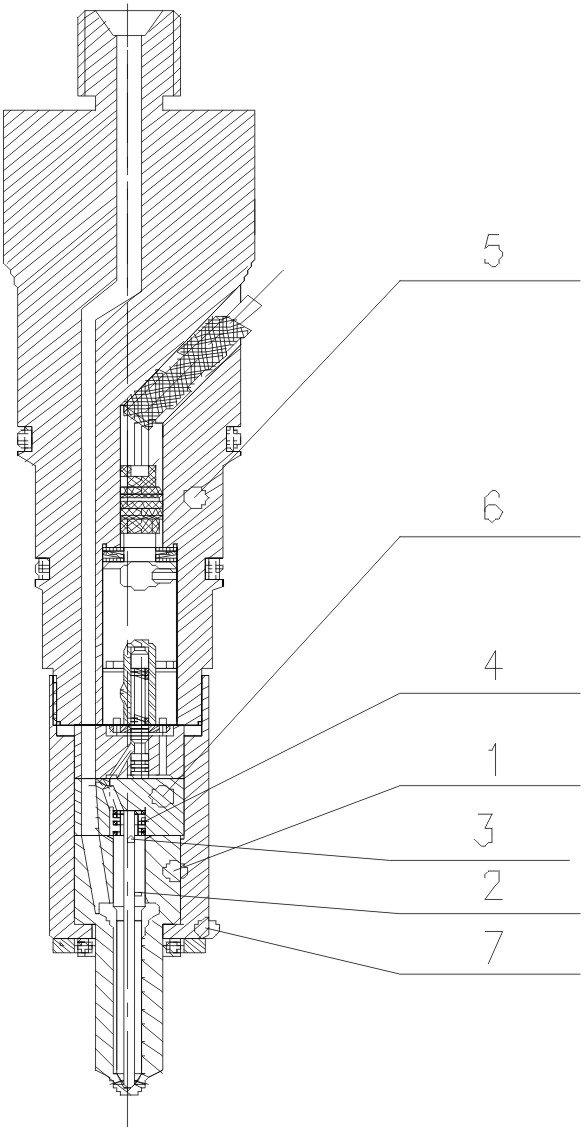

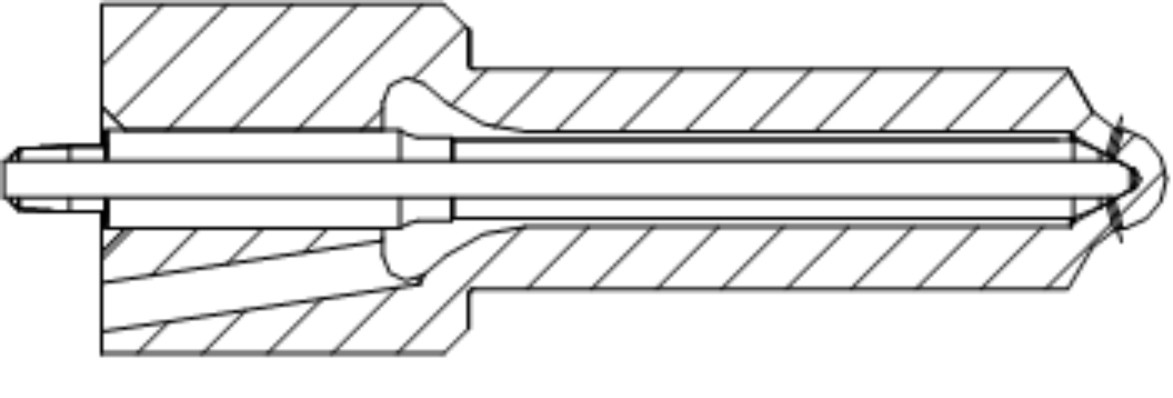

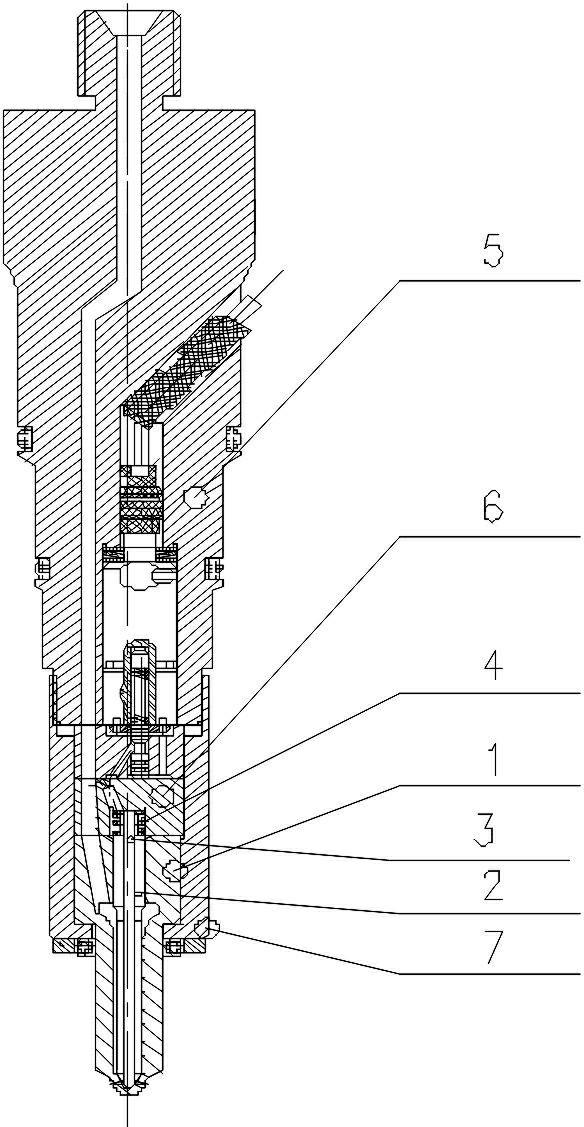

[0010] A fuel injector assembly for a diesel engine, which includes a fuel injector body 1, a fuel injector needle valve 2, a needle valve guide rod 3, a needle valve spring 4, a fuel injector body 5, a fuel injector middle piece 6 and a pressure Tightening nut 7, fuel injector body 1, fuel injector needle valve 2 and needle valve guide rod 3 form a hydraulically balanced fuel injector pair, fuel injector needle valve 2 is set in fuel injector body 3, and the injector The needle valve 2 of the fuel nozzle is provided with a needle valve guide rod 3, the hydraulically balanced fuel injector assembly is disposed under the injector intermediate body 6, and the needle valve spring 4 is disposed at the root of the needle valve 2 of the fuel injector. The intermediate body 6 of the injector and the pair of hydraulically balanced injectors are arranged under the injector body 5 through the compression nut 7 . The needle valve guide rod 3 is always pressed against the head of the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com