Fuel feed system oil sprayer and oil spray nozzle thereof

A technology of fuel supply system and fuel injector, which is applied in the direction of charging system, fuel injection device, machine/engine, etc. It can solve the problems of difficult processing, high cost, complex structure of fuel injector head, etc., and achieve simplified processing , improve the accuracy of parts, and simplify the electronic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

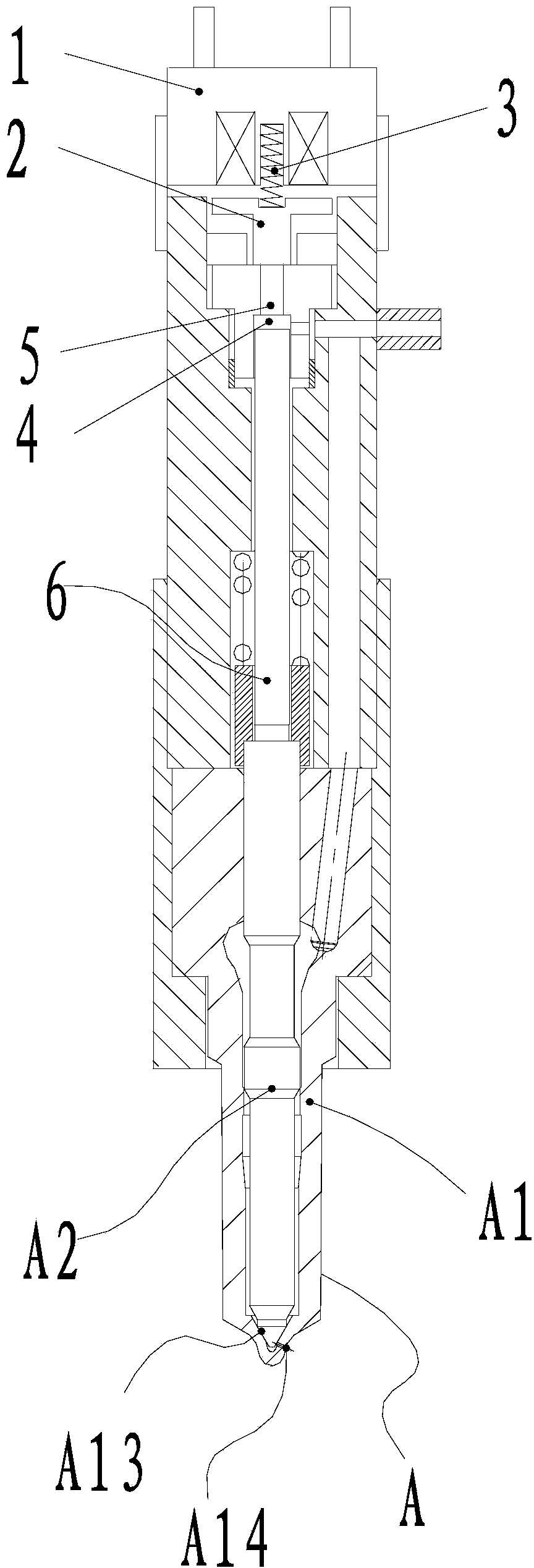

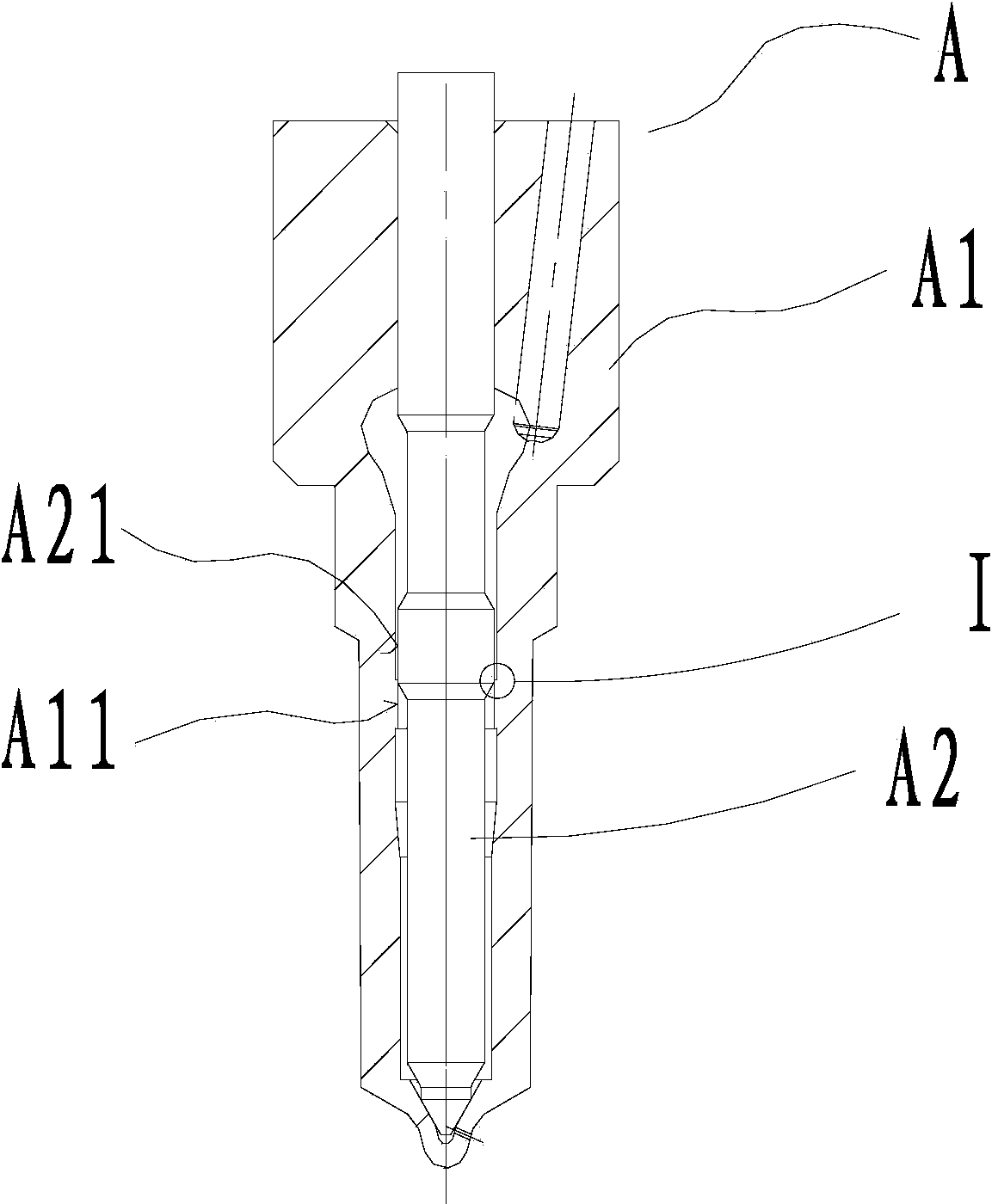

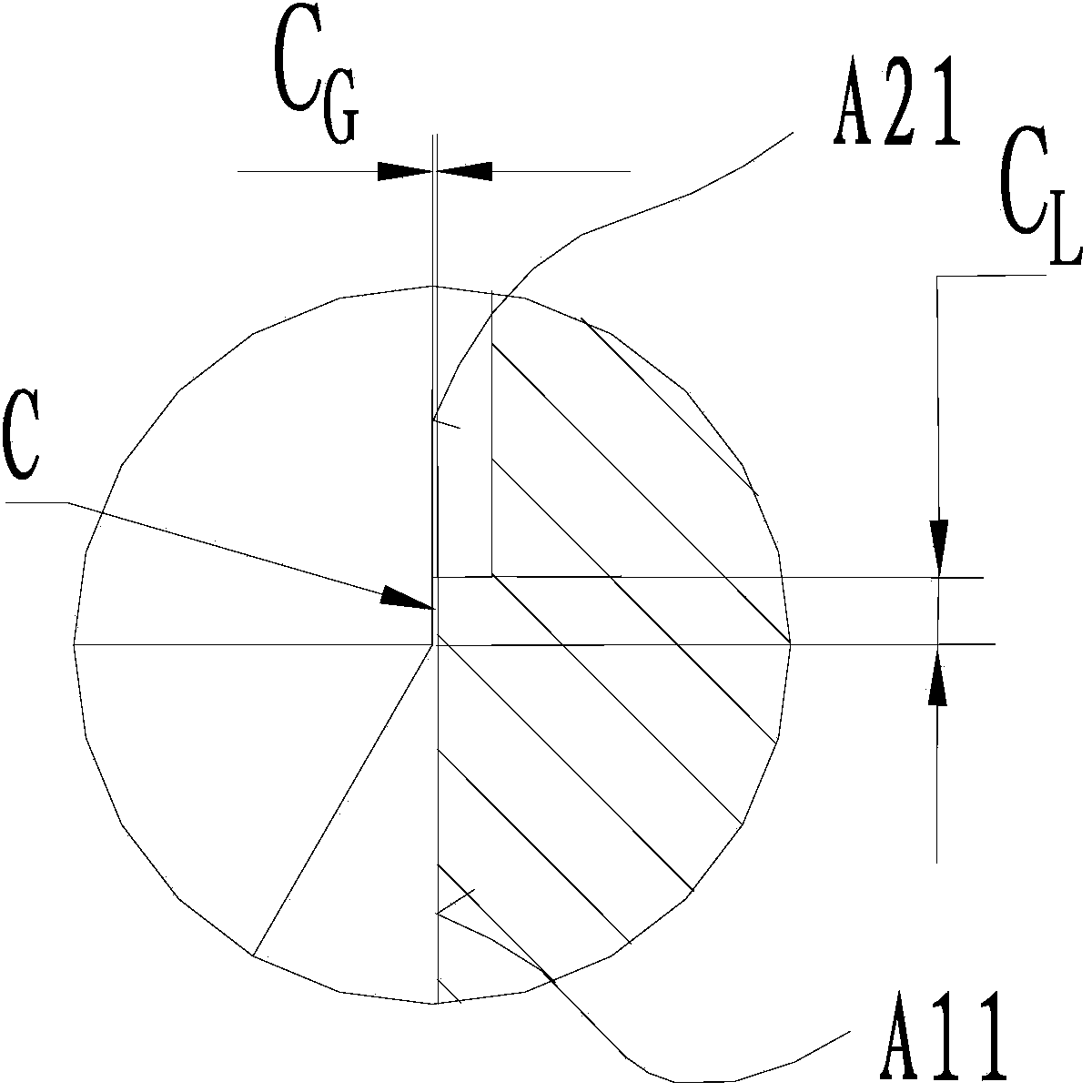

[0037] Such as Figure 2-5 As shown, the fuel injector A includes a needle valve body A1 and a needle valve A2, which are mated with each other. A first flange A11 is formed on the inner wall of the needle valve body A1, and the first flange A11 encloses an orifice, and the diameter of the orifice is consistent with the diameter of the coupling seal (coupling guide hole). A second flange A21 is configured on the outer wall of the needle valve A2; when the needle valve A2 is closed, a throttle ring C is formed between the vertical inner wall of the first flange A11 and the vertical outer wall of the second flange A21; When the needle valve A2 is fully opened, there is no matching section between the vertical inner wall of the first flange A11 and the vertical outer wall of the second flange A21 (that is, the throttle ring C disappears and does not work).

[0038] The throttling gap width of the throttle ring C between the first flange A11 and the second flange A21 is C G , wh...

Embodiment 2

[0041] The difference from Embodiment 1 is that the position of the throttle hole is different from the diameter of the throttle hole. Such as Figure 6-7 As shown, a first flange A11 is constructed on the inner wall near the head of the needle valve body A1, and the first flange A11 encloses an orifice; when the needle valve A2 is closed, the vertical inner wall of the first flange A11 Cooperate with the cylindrical outer wall of the needle valve A2 to form a throttle ring C; when the needle valve A2 is fully opened, there is no matching section between the vertical inner wall of the first flange A11 and the cylindrical outer wall of the needle valve A2 (that is, the throttle ring C disappears, does not work).

[0042]The advantage of the above structure is that the structure of the needle valve is not changed, and a throttle hole is constructed on the needle valve body. The diameter of the orifice is determined according to the diameter of the outer circle of the needle va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com