Slewing bearing ball belt-type locating retainer

A technology of slewing bearing and cage, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of limited use range of slewing bearings, increased circumferential gap between balls, and noise caused by collision of isolation blocks, and achieves expanded use. The effect of improving performance such as field, starting torque and noise, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

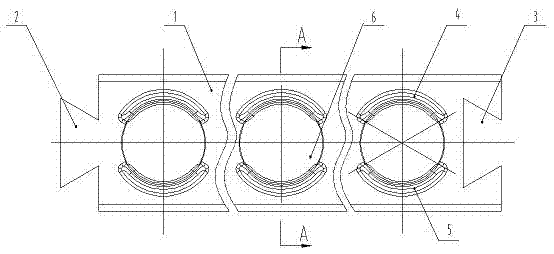

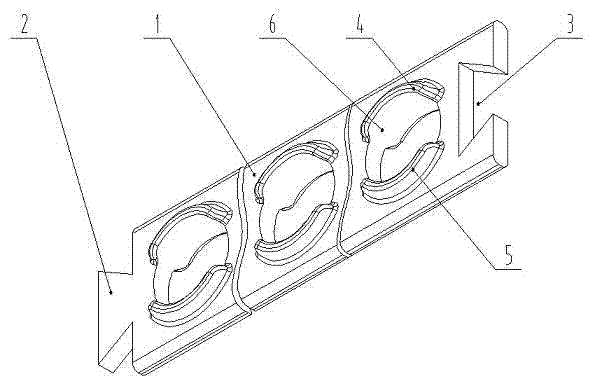

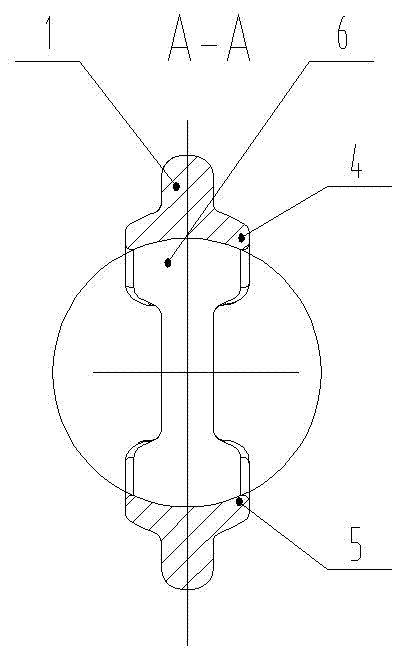

[0012] From Figure 1-Figure 3 It can be seen from the figure: a slewing bearing ball belt type positioning cage, which is characterized in that the slewing bearing ball belt positioning cage is mainly composed of a belt body 1, a ball seat hole 6, an upper arc-shaped boss 4 and a lower arc Shaped boss 5, the belt 1 is a long belt with a flat rectangular cross section, the upper and lower sides of the belt 1 are circular arc transitions, and the left end of the belt 1 is provided with a dovetail joint 2, and on the left end of the belt 1 The right end of the belt body 1 is correspondingly provided with a dovetail groove 3, and the dovetail joint 2 and the dovetail groove 3 are correspondingly embedded to form a complete circle, which is used as a cage body for each ball, and the length of the belt body 1 can be adjusted according to the slewing support roller. The circumference of the center of the track is intercepted, and the versatility is strong. The upper and lower parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com