Temperature-variation-resistant low-wear self-lubricating linear bearing

A linear bearing and low-wear technology, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of loose connection flange connection, cumbersome ball lubrication methods, and inability to achieve self-lubrication, etc., to expand the installation angle, increase the The effect of wide application range and improved operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

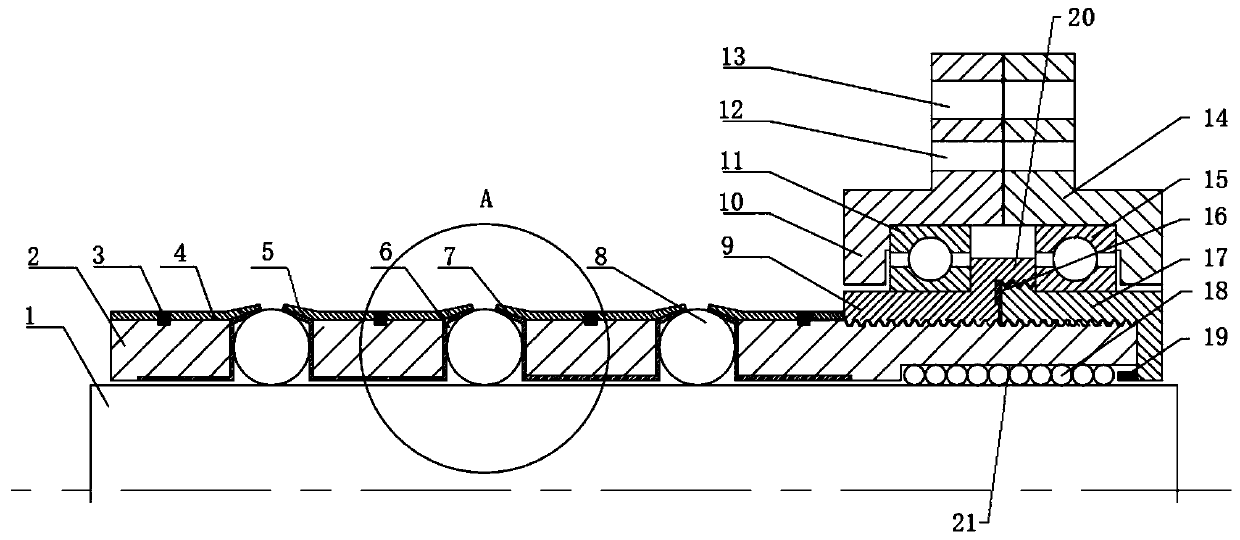

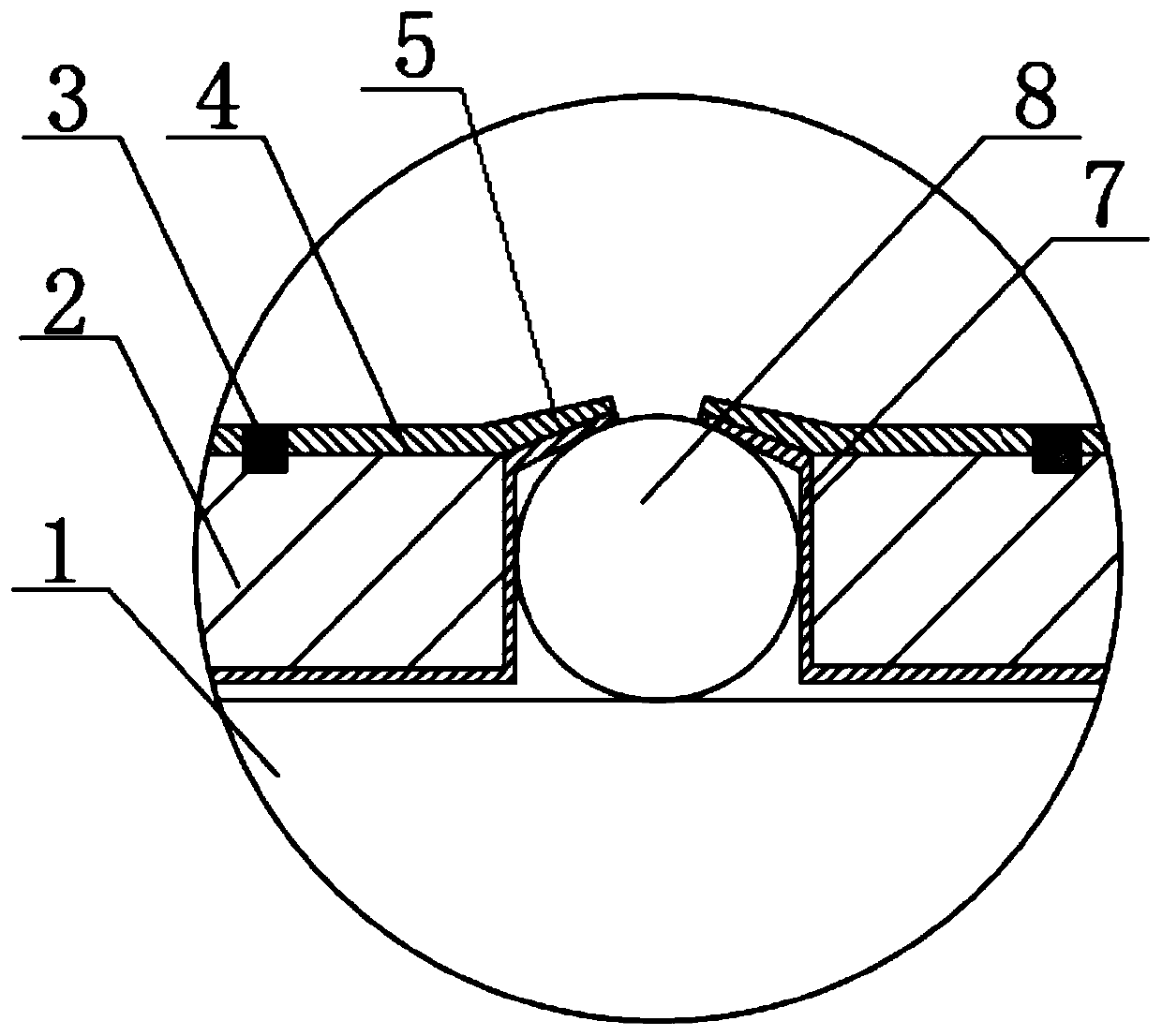

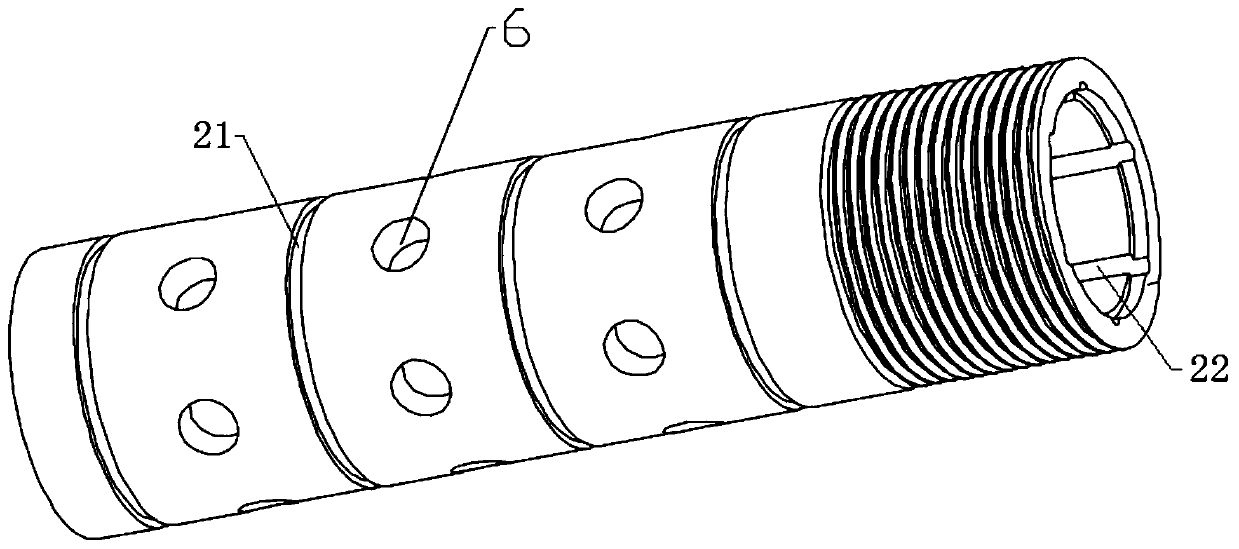

[0029] Such as Figures 1 to 4 As shown, a temperature-resistant and low-wear self-lubricating linear bearing includes a guide shaft 1, a bearing ring 2 and a ball 8. The bearing ring 2 is sleeved on the outer periphery of the guide shaft 1, and its side wall is provided with several groups along the axial direction. The round holes 6 are arranged at equal intervals, and each group of round holes 6 is evenly arranged along the circumferential direction. Preferably, six groups of three round holes 6 are arranged in the axial direction. A ball 8 is rotatably arranged in each circular hole 6 , and the surface of the ball 8 is in contact with the outer peripheral surface of the guide shaft 1 to form a rolling connection between the bearing ring 2 and the guide shaft 1 . The outer circumference of the bearing ring 2 is provided with a fixed sleeve 4, and the fixed sleeve 4 forms a number of elastic pressing pieces 5 at least at the round hole 6. In this embodiment, the fixing sleev...

Embodiment 2

[0037] The difference from Embodiment 1 is that in this embodiment, the fixed sleeve 4 is a split structure, that is, a bearing ring 2 is provided with a plurality of fixed sleeves 4, and each fixed sleeve 4 is provided with a number of elastic rings arranged in the circumferential direction. Pressing sheet 5, thereby compressing the balls-8 in a group of circular holes 6 covered by it. The space between two adjacent fixing sleeves 4 is blocked by the vibration damping ring 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com