Rotor blade for a wind turbine

A technology of rotor blades and wind energy equipment, which is applied to wind power generation, mechanical equipment, and wind turbines in the same direction as the wind to achieve the effect of reducing the angle of attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

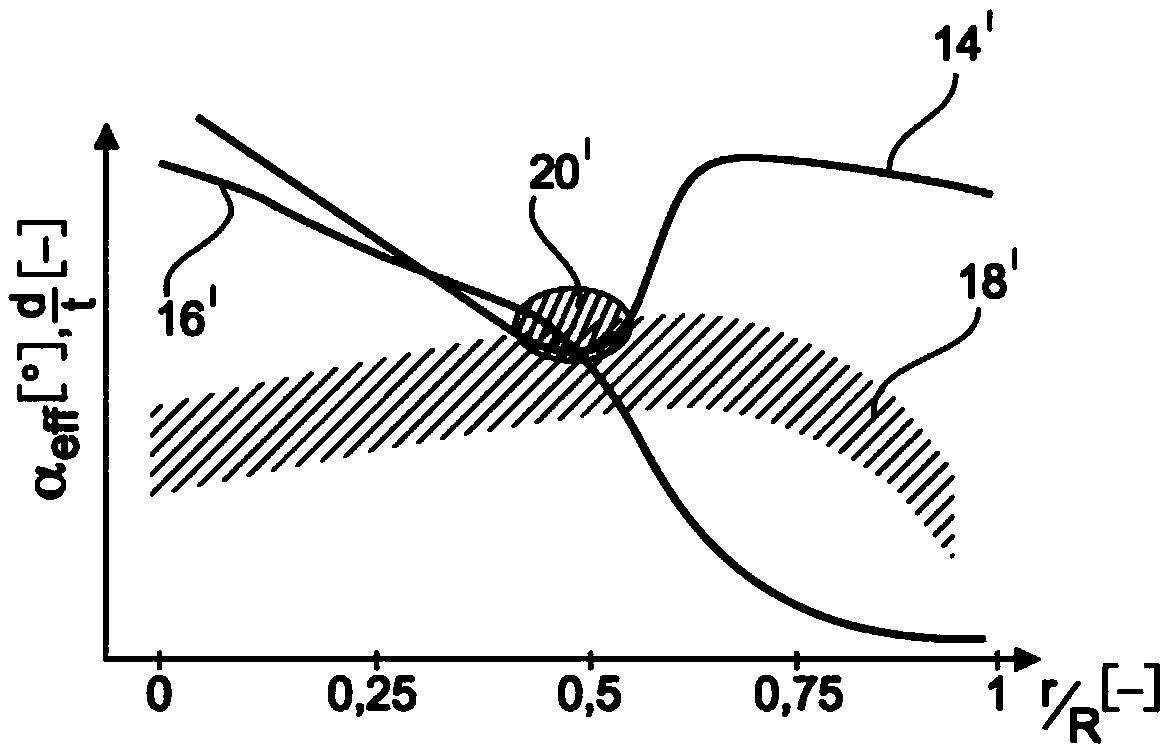

[0042] Figure 1a A diagram is shown in which the maximum permissible angle of attack 14', ie the stall angle, and the relative profile thickness 16' are schematically plotted as a function of their position r along the longitudinal axis of the blade. The position r is specified in a normalized manner by its relative radius r / R with respect to the outer radius R of the rotor, with values from 0 to 1, which thus correspond to values from 0% to 100%. Figure 1a The ratios are shown as usually exist in rotor blades according to the prior art. exist Figure 1a In the graph of , the stall angle 14' is plotted as the limiting angle 14' of a contaminated or wet rotor blade. The limit angle 14' can here be regarded as the maximum permissible effective angle of attack α of the rotor blades during operation of the wind turbine eff . additionally, in Figure 1a The graph 16' of the relative profile thickness d / t of a prior art rotor blade is shown.

[0043] The curve 14' of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com