Glucose sensor electrode and manufacturing method thereof

A glucose sensor and electrode technology, applied in the field of biosensors, can solve the problems of patient pain, non-continuous detection, limited number of measurements, etc., and achieve the effect of high catalytic response current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An electrolyte solution with a concentration of 2.5 mg / ml was prepared, and the electrolyte solution was composed of chloroplatinic acid, lead acetate, and hydrochloric acid. The concentration of hydrochloric acid in the electrolyte is fixed at 0.5mol / L, and the molar ratio of the solid matter in the electrolyte is chloroplatinic acid:lead acetate=1:1. At room temperature, take the processed stainless steel acupuncture needle electrode, control the deposition current to 5mA, and the deposition time to 10 minutes. In the electrolyte of the above configuration, constant current ultrasonic vibration 200w co-deposition. The prepared electrode was rinsed with twice distilled water, dried at room temperature, and stored in a refrigerator at 4°C until use.

Embodiment 2

[0025] An electrolyte solution with a concentration of 1 mg / ml was prepared, and the electrolyte solution was composed of chloroplatinic acid, lead acetate, and hydrochloric acid. The concentration of hydrochloric acid in the electrolyte is fixed at 0.5mol / L. The molar ratio of solid matter in the electrolyte is chloroplatinic acid:lead acetate=1:1. At room temperature, take the processed stainless steel acupuncture needle electrode, control the deposition current to 40mA, and the deposition time to 20 minutes. In the electrolyte of the above configuration, constant current ultrasonic vibration 100w co-deposition. The prepared electrode was rinsed with twice distilled water, dried at room temperature, and stored in a refrigerator at 4°C until use.

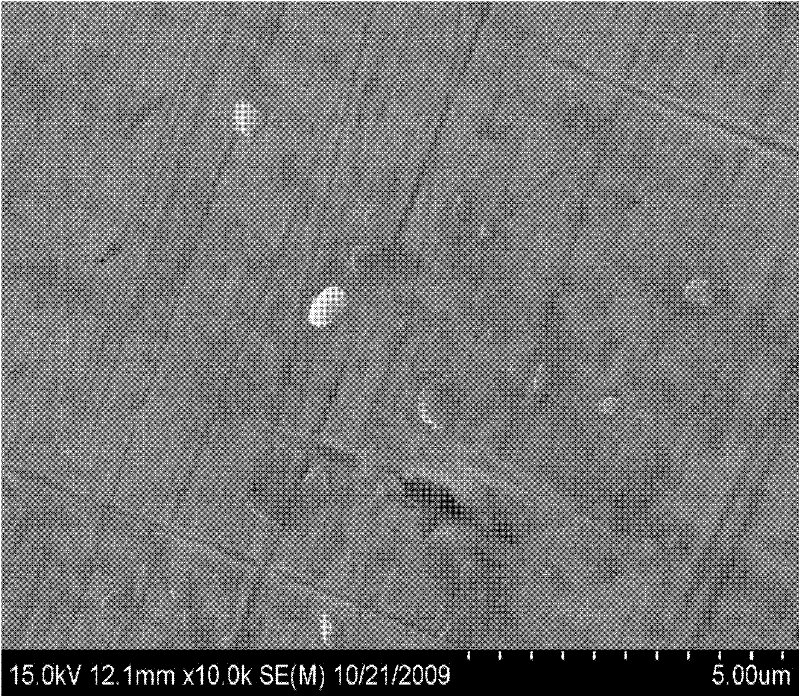

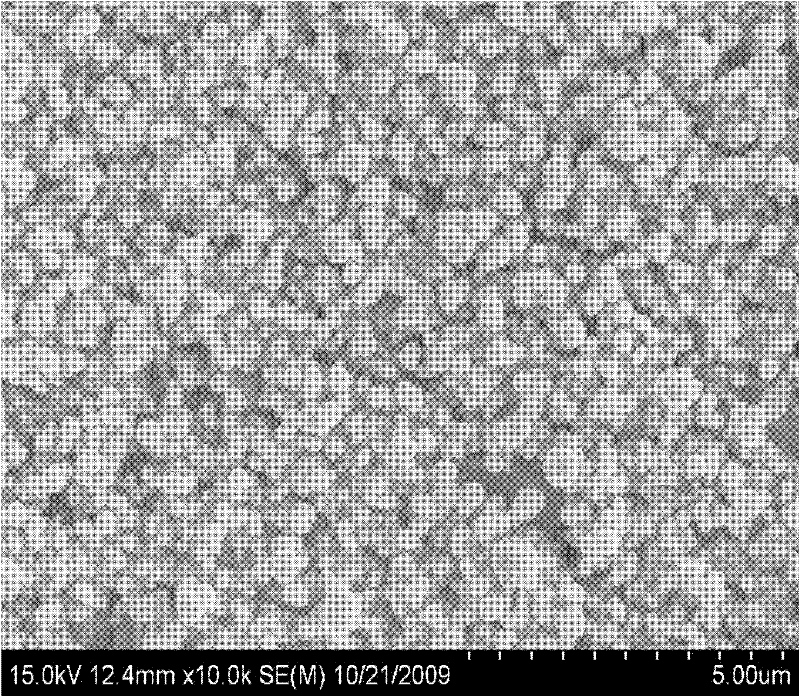

[0026] Select the prepared electrode sample to analyze its surface morphology on the XL-30 scanning electron microscope, such as figure 2 Shown is a 10,000X scanning electron microscope picture of the electrode surface modified ...

Embodiment 3

[0028] An electrolyte solution with a concentration of 5 mg / ml was prepared, and the electrolyte solution was composed of chloroplatinic acid, lead acetate, and hydrochloric acid. The concentration of hydrochloric acid in the electrolyte is fixed at 0.5mol / L. The molar ratio of solid matter in the electrolyte is chloroplatinic acid:lead acetate=1:1. At room temperature, take the processed stainless steel acupuncture needle electrode, control the deposition current to 20mA, and the deposition time to 40 minutes. In the electrolyte of the above configuration, constant current ultrasonic vibration 100w co-deposition. The prepared electrode was rinsed with twice distilled water, dried at room temperature, and stored in a refrigerator at 4°C until use.

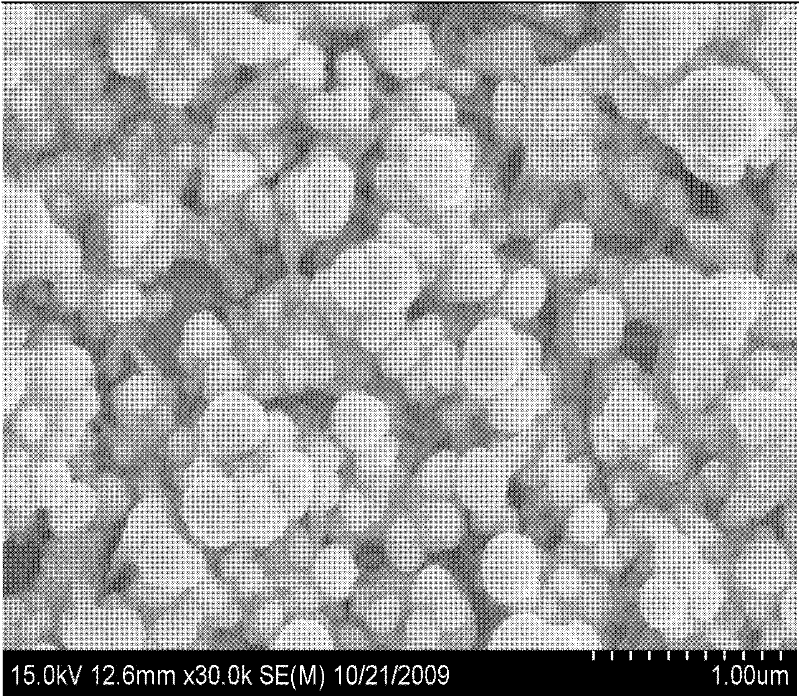

[0029] Select the prepared electrode sample to analyze its surface morphology on the XL-30 scanning electron microscope, such as image 3 Shown is a 30000 times scanning electron microscope picture of the surface of the electrode...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap