Automatic widening device for automatic acupuncture needle handle winding machine

A handle winding machine and acupuncture needle technology, applied in acupuncture and other directions, can solve the problems of low production efficiency and high labor intensity, and achieve the effects of reasonable structure, reliable work, and improved automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

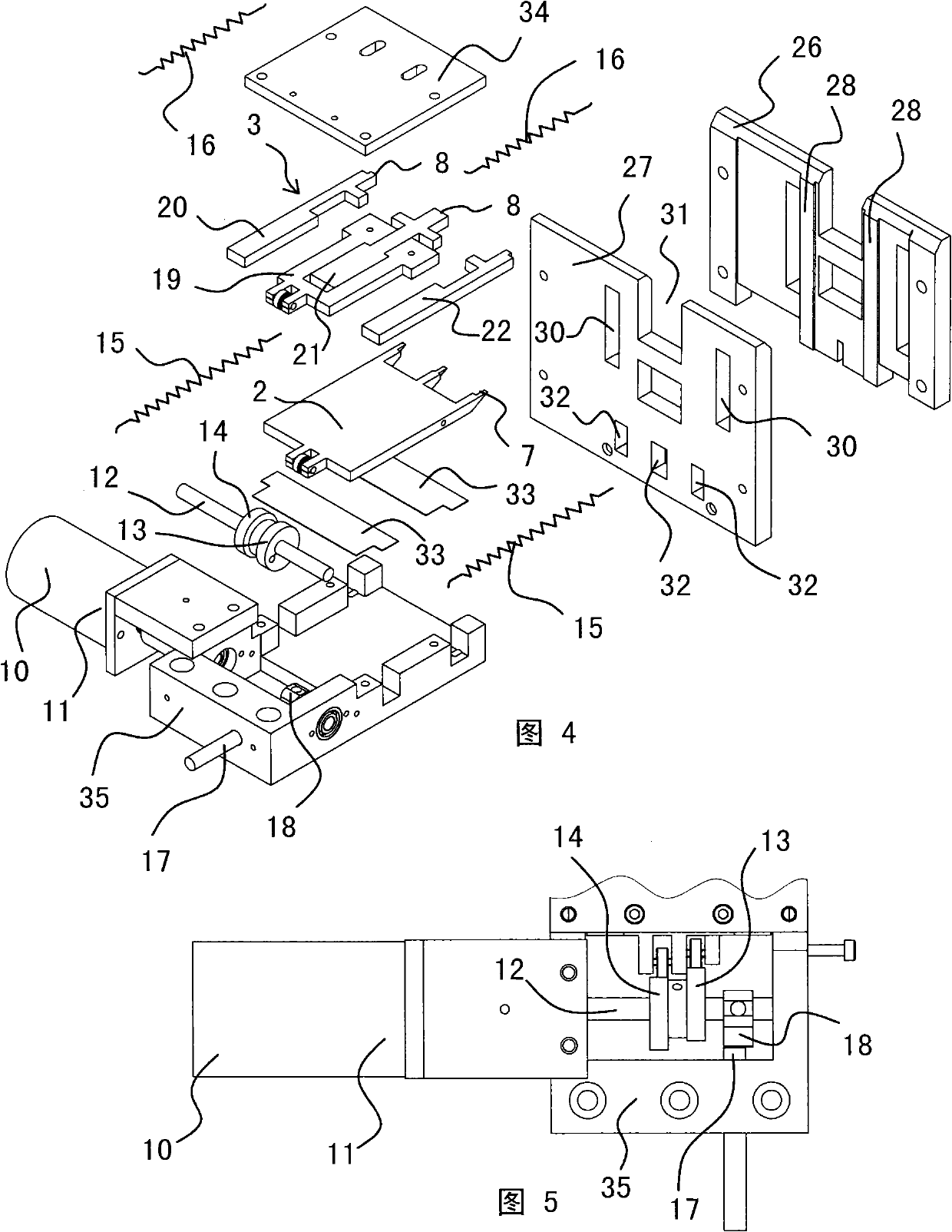

[0026] Embodiment: An automatic needle setting device of an acupuncture needle automatic handle winding machine, which is composed of two parts: a needle setting mechanism and a driving mechanism.

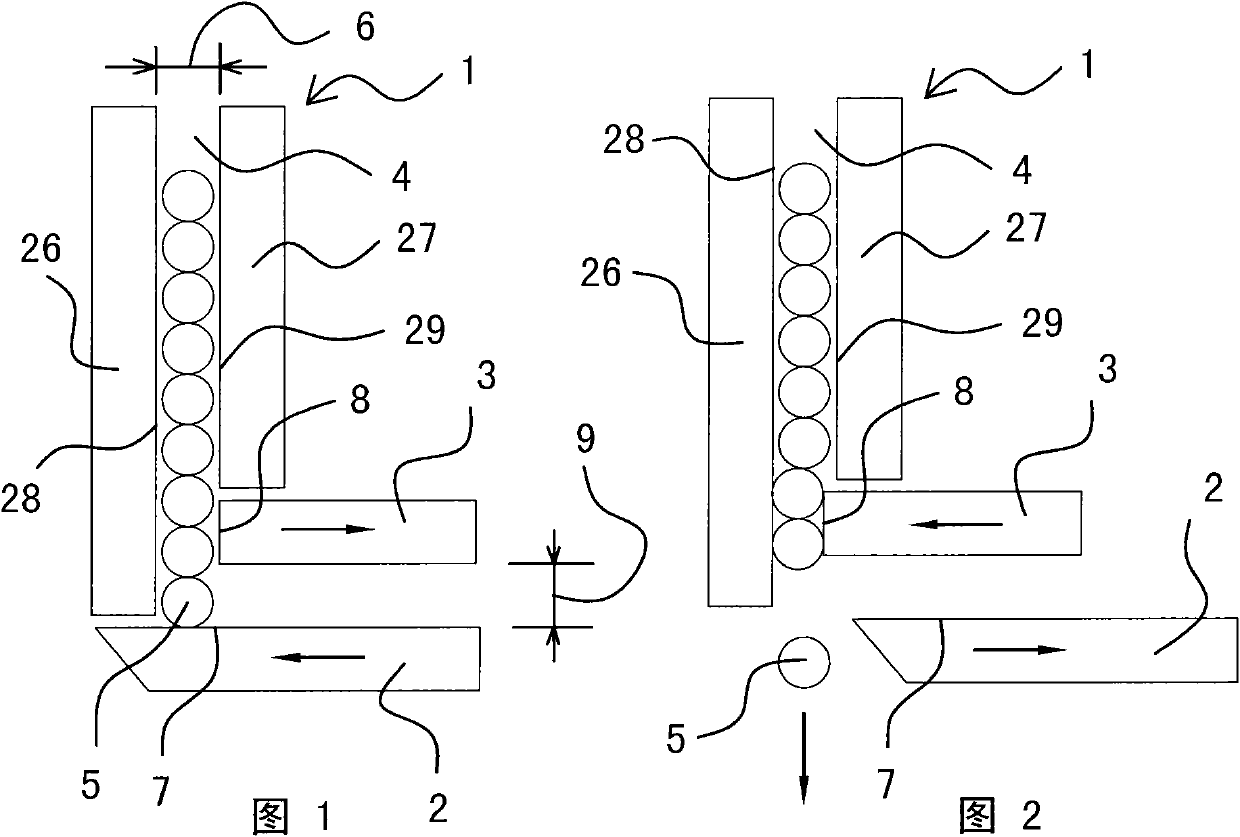

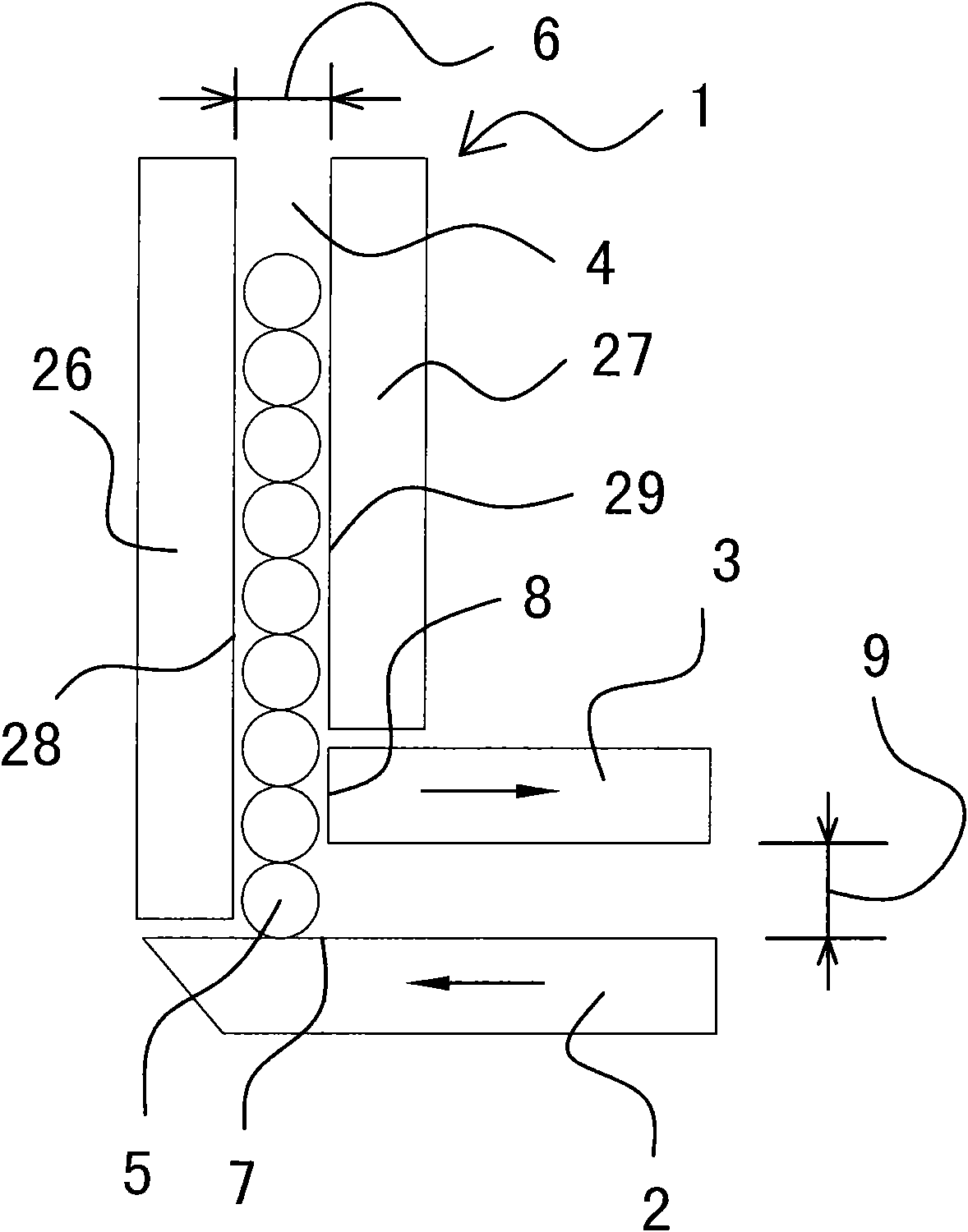

[0027] see Figure 1~6 As shown, the needle setting mechanism is mainly composed of gravity needle drop groove 1, needle supporting plate 2 and ejector plate 3 (see figure 1 or figure 2 ), wherein, the gravity needle drop groove 1 has a section of needle drop channel 4 arranged longitudinally, and the needle drop size in the longitudinal direction on the cross section of the needle drop channel 4 is greater than the length of the needle blank 5 (so that the needle blank 5 can be placed horizontally on the needle drop channel In the channel 4), the needle drop gap 6 in the width direction is greater than the diameter of the needle blank 5 and less than twice the diameter of the needle blank 5 (so that the needle blanks 5 can be arranged in parallel in the needle drop channel from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com