Method for controlling the regeneration cycles for an air dryer in a closed ride control system for vehicles

An air dryer, height adjustment technology, applied in chemical instruments and methods, separation methods, vehicle components, etc., can solve problems such as switching to closed pneumatic systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

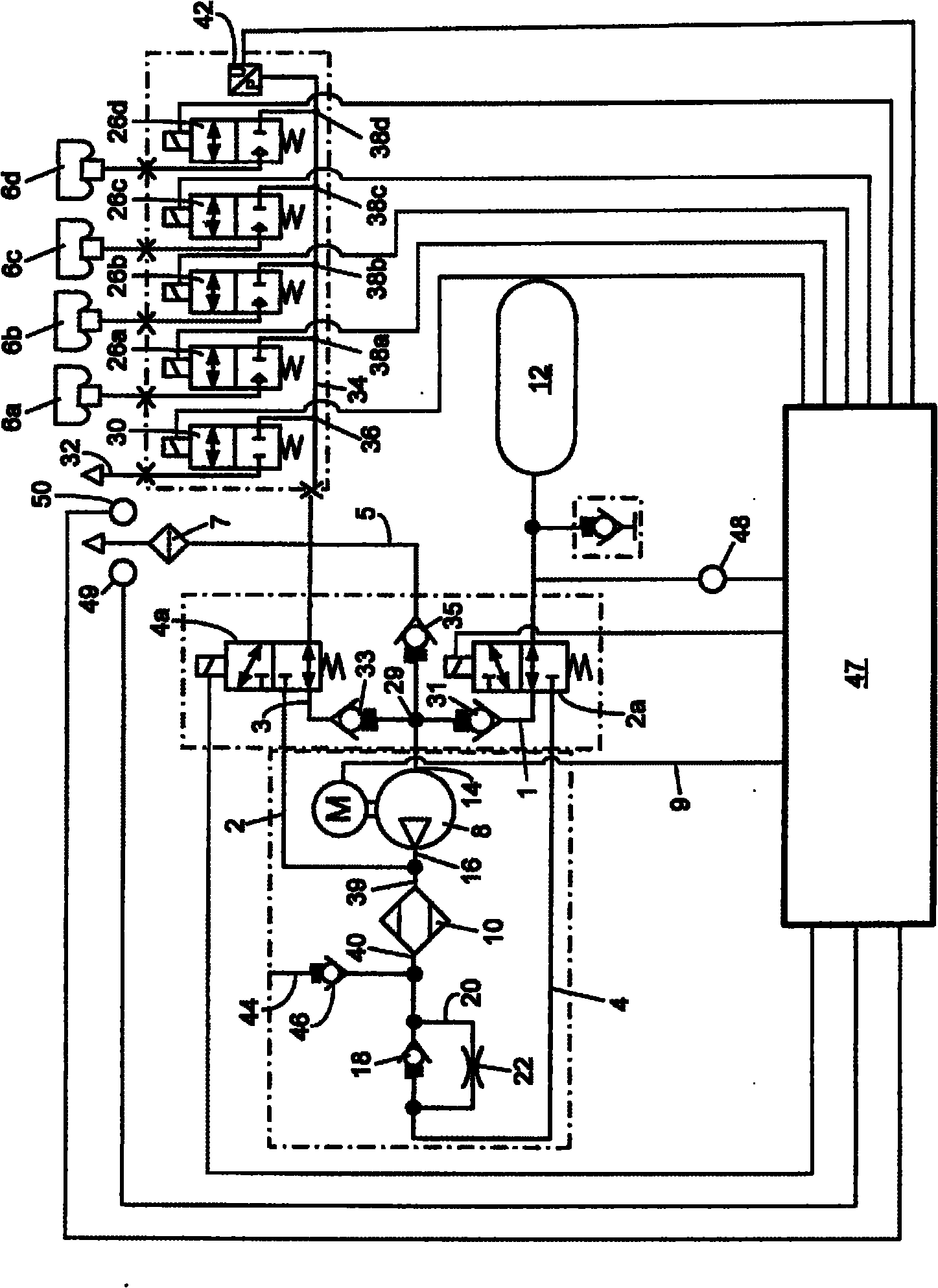

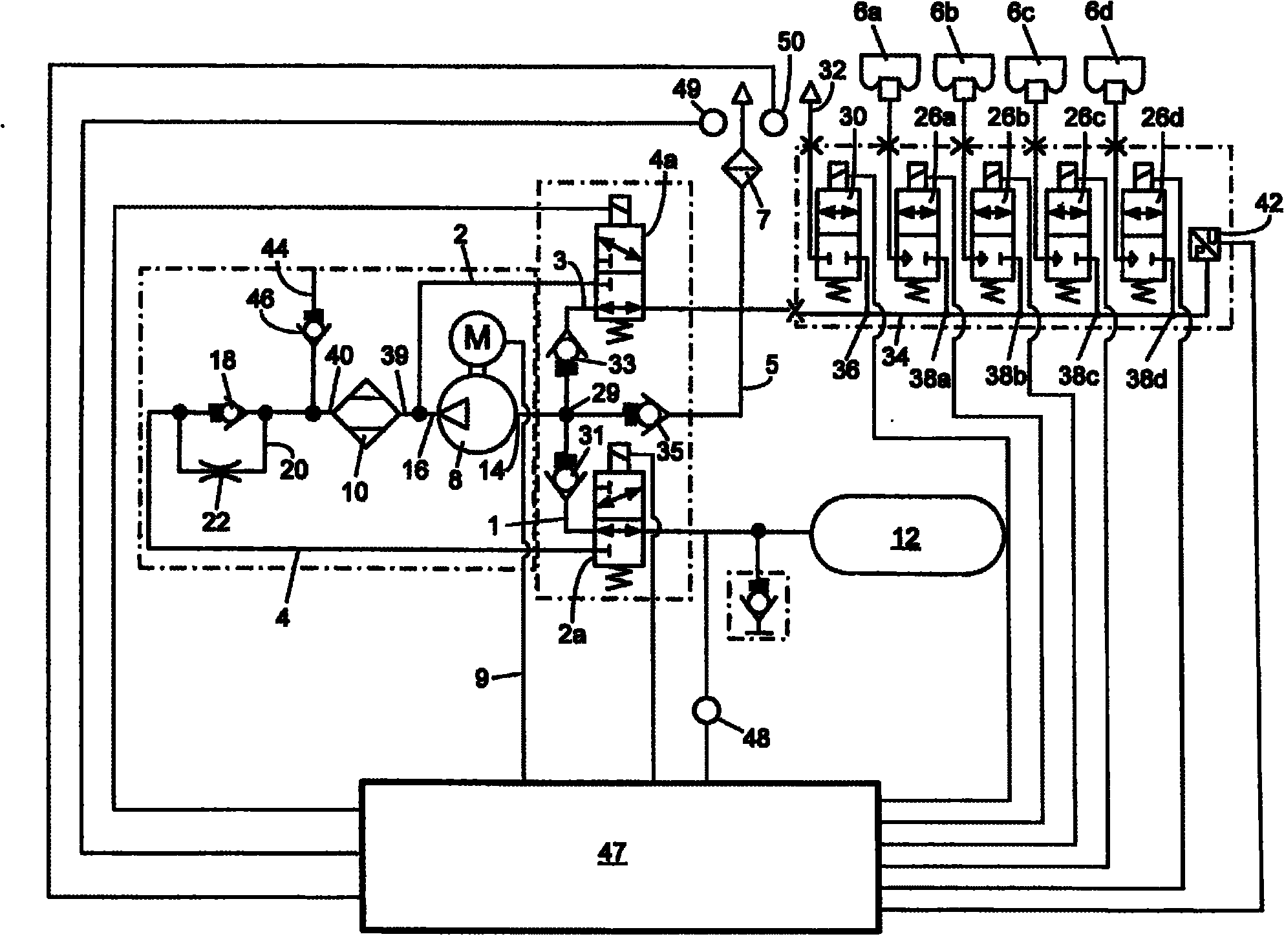

[0021] The only figure schematically shows the pneumatic circuit diagram of a closed ride height adjustment system according to the invention, which operates with compressed air and comprises pressure medium chambers in the form of air springs 6a to 6d, compression Machine 8, air dryer 10 and pressure medium storage container 12. The pressure medium storage container 12 is connected to the compressor input end 14 through the first pressure medium pipeline 1 and is connected to the compressor output end 16 through the first two-position three-way reversing valve 2a and the fourth pressure medium pipeline 4. The first pressure medium pipeline 1 passes through a controllable two-position three-way reversing valve 2 a and a check valve 31 , and a check valve 18 and an air dryer 10 are arranged in the fourth pressure medium pipeline 4 . The non-return valve 18 is arranged to open towards the pressure medium storage container 12 .

[0022] A compressed air line 20 runs parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com