Module for the modular frame of a heavy load transport vehicle

A transport vehicle and modular technology, which is applied in the fields of heavy-duty loading and unloading, port vehicles, and modular frames for heavy-duty transport vehicles, tools, and modular frames, which can solve the problem of energy performance burden, heavy weight, and high consumption Steel and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] More specifically, the present invention relates to the field of heavy haulage, especially portage.

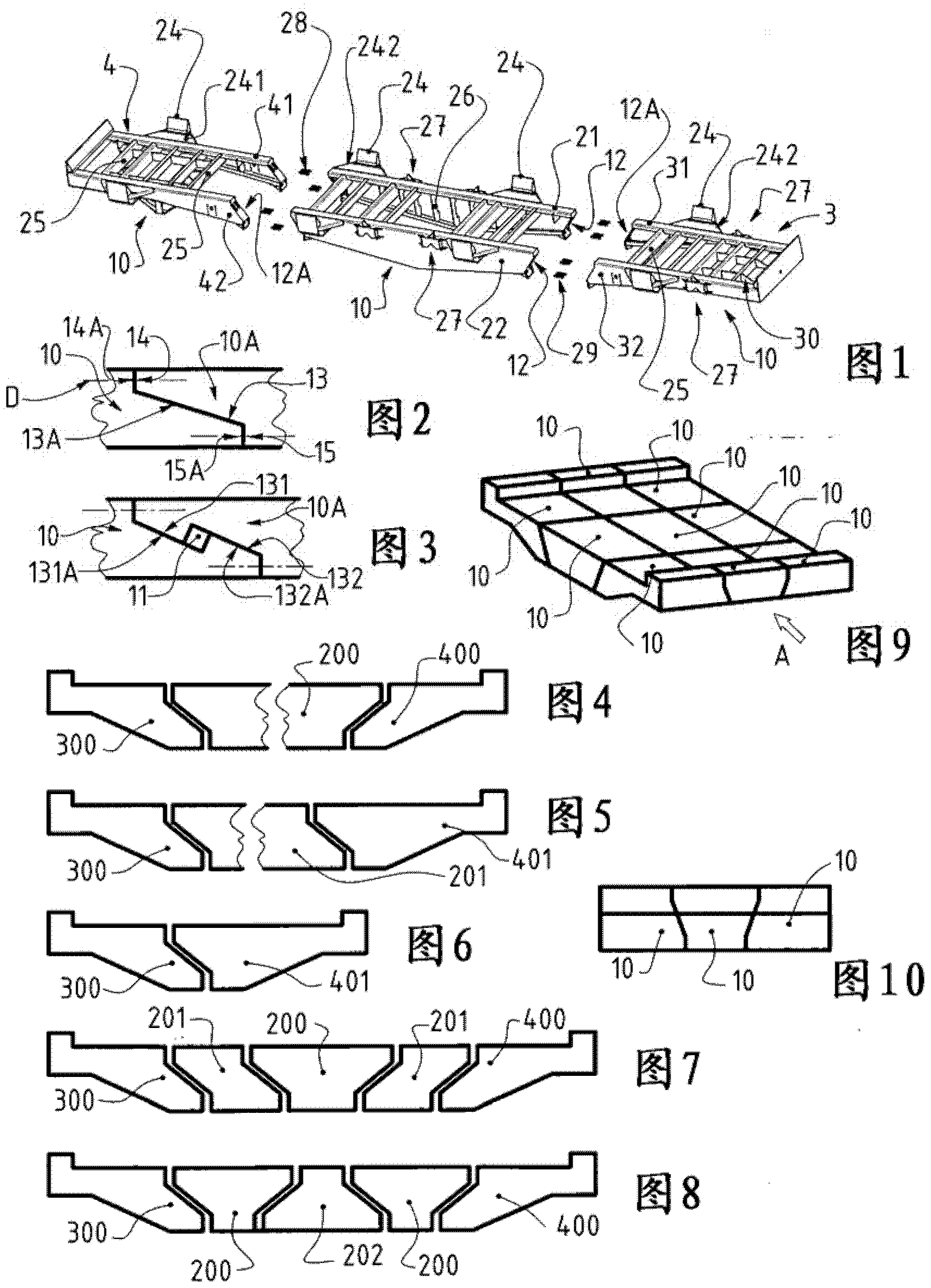

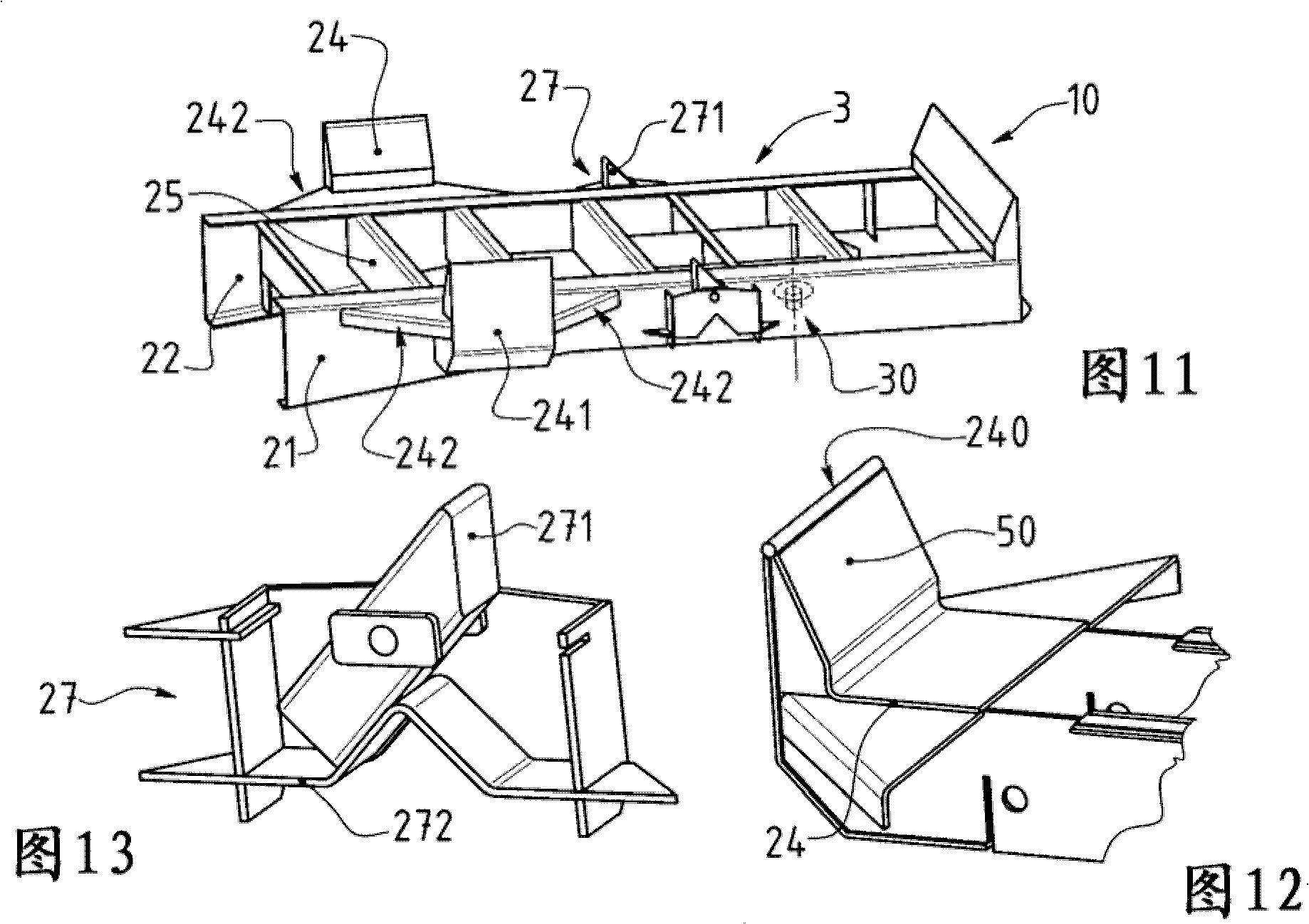

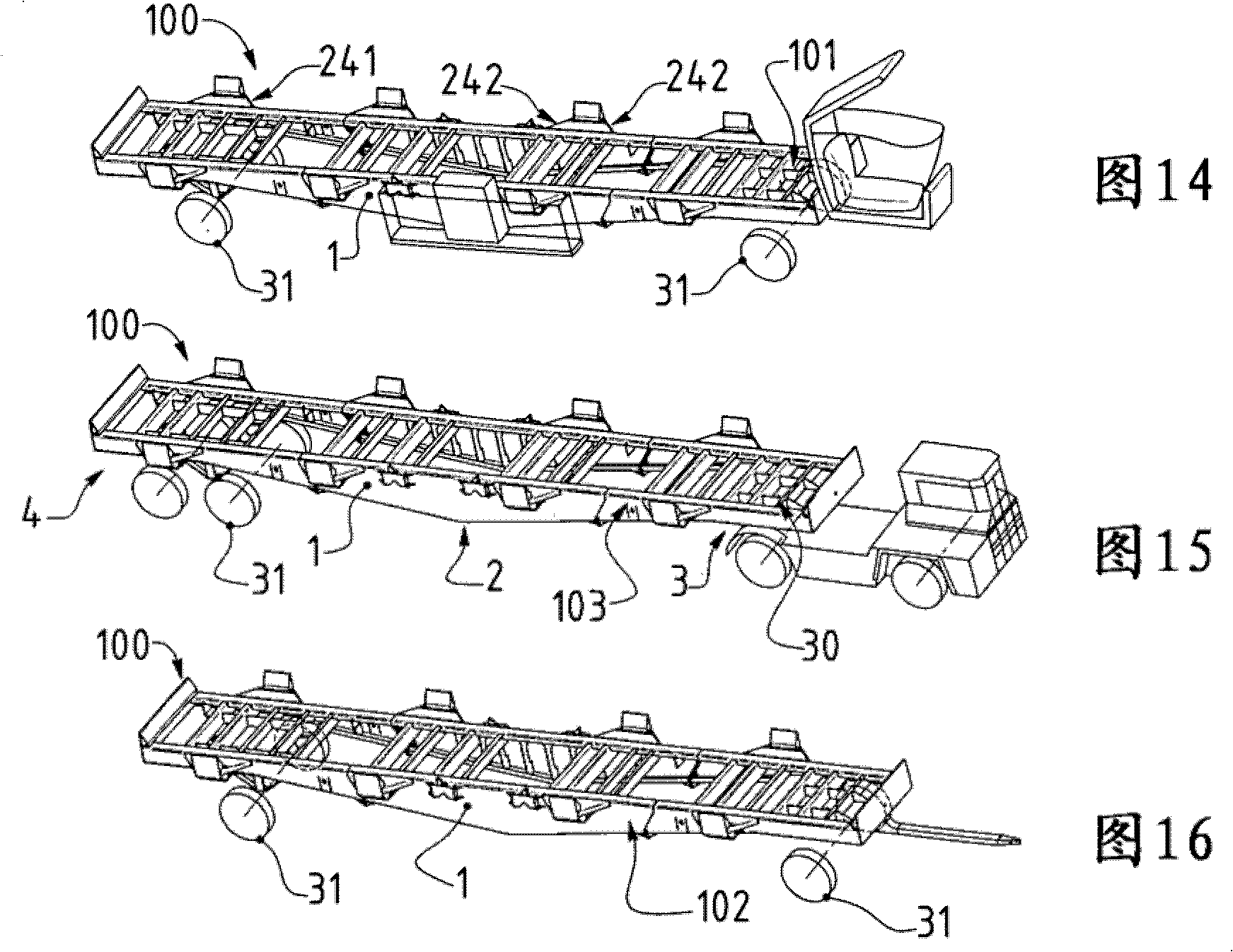

[0033] The invention relates to a module 10 for a modular frame 1 of a heavy-duty transport vehicle 100 .

[0034] Such modules 10 may take different forms, as can be seen in the following statements, examples of modules 10 indicated by reference numerals 2, 3, 4, 200, 201, 202, 300, 400, 401.

[0035] According to the invention, in order to at the same time ensure optimum bending resistance of the frame 1 of a vehicle 100 constructed with such a module 10, the module 10 comprises at least one of its ends a joint surface 12 comprising at least one inclined support surface 13, The inclined support surface extends between two mutually parallel planar surfaces 14 and 15 which are inclined relative to the inclined support surface 13 .

[0036] Such a module 10 is designed to cooperate, as the case may be, with the structure to which it is connected, or with another module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com