Water curtain machine with sieve flusher

A technology of flushing device and water curtain machine, which is applied in the direction of combined device, use of liquid separation agent, separation of dispersed particles, etc., and can solve problems such as unsuitable for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

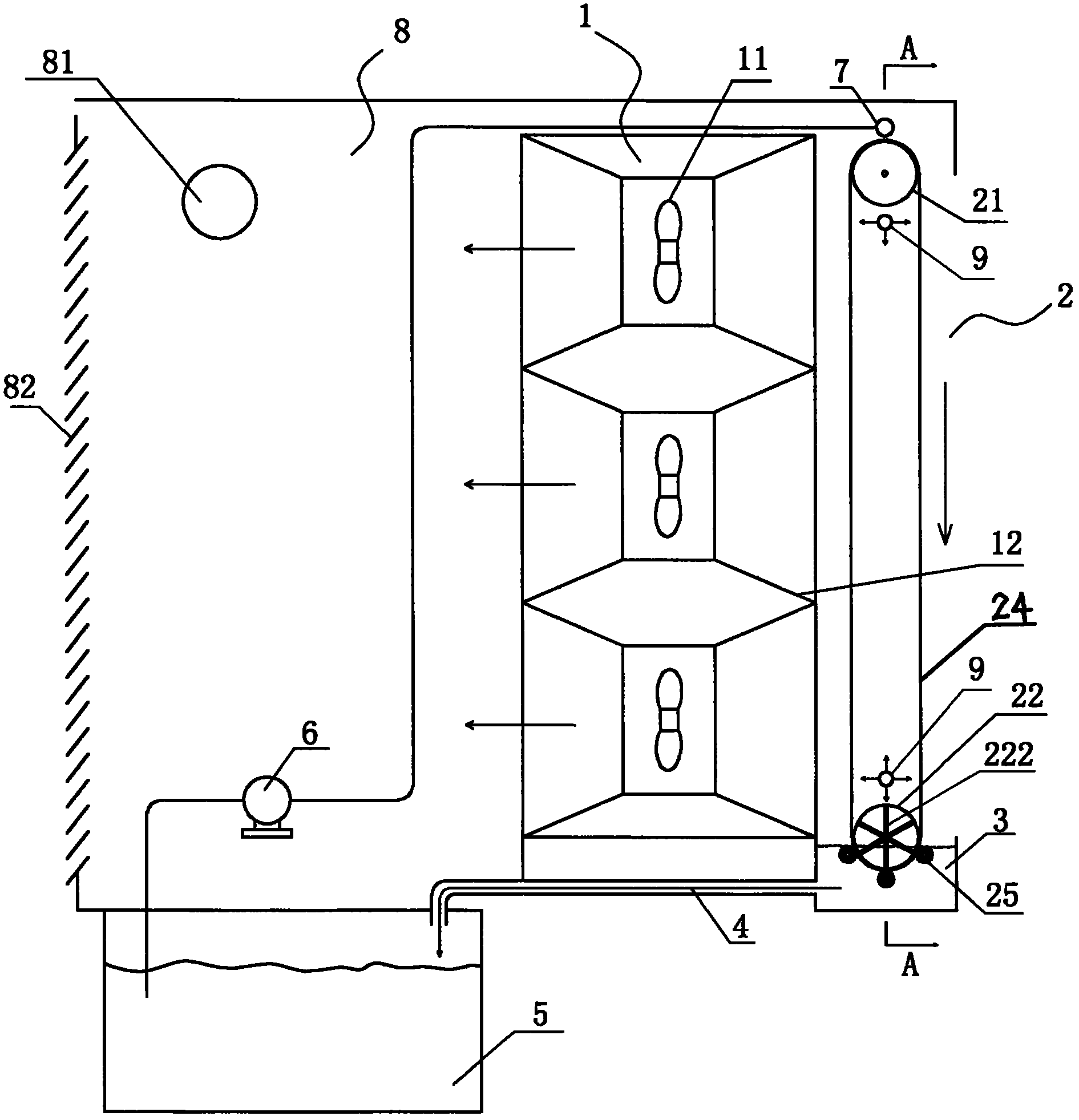

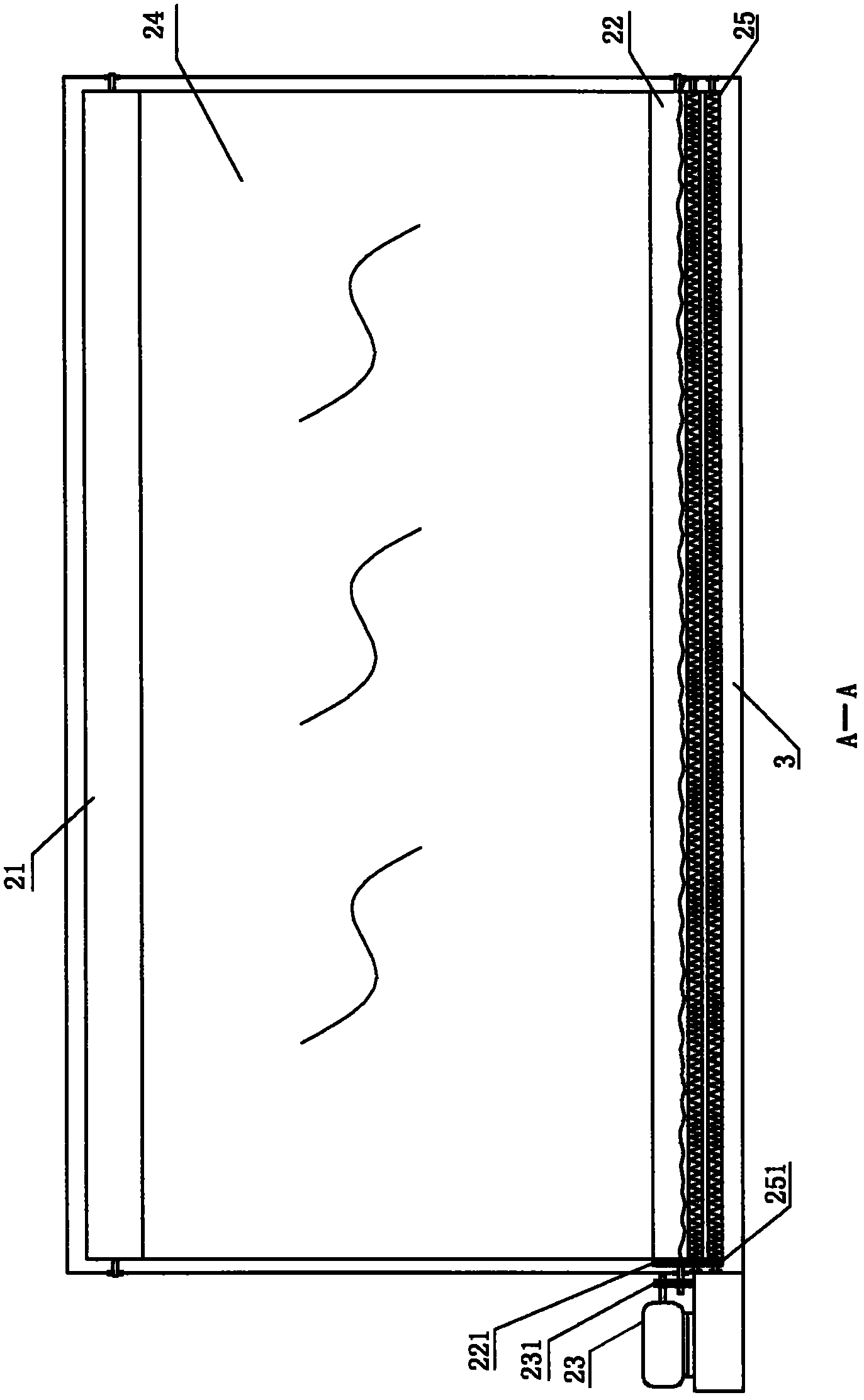

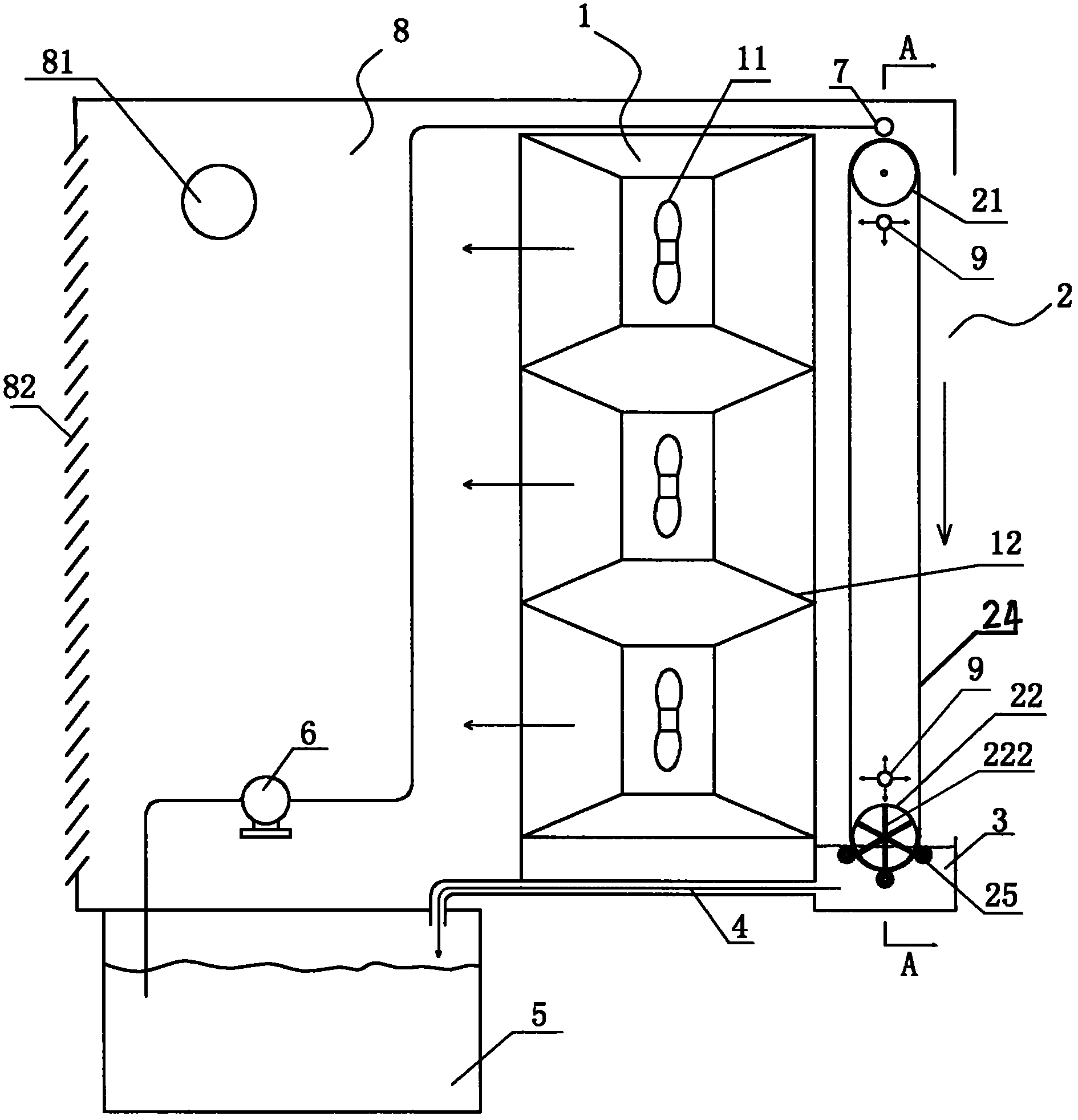

[0015] Such as figure 1 , figure 2 As shown, a water curtain machine with a filter flushing device is mainly composed of a suction and exhaust device 1, a dust filter device 2, a filter water tank 3, a drain pipe 4, a water storage tank 5, a circulating water pump 6, a water delivery pipe 7, an air Purifying device 8 is made up of, and described dust filtering device 2 is arranged on the top of filtering water tank 3, comprises upper roller shaft 21, lower roller shaft 22, power unit 23, filter screen 24 that is sleeved on the upper roller shaft and the lower roller shaft, As well as the dust removal device 25 located in the filtered water tank 3, more than one spray water pipe 9 is arranged in the space between the upper roller shaft 21 and the lower roller shaft 22. The water mist sprayed by the spray water pipe 9 has two functions, one is to absorb the dust in the air entering the filter screen, so that the dust falls down to the lower roller shaft, and the other is to sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com