Adjusting device

A technology of adjusting devices and pin shafts, which is applied in printing and other directions, can solve the problems of reducing accuracy and prone to crawling, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

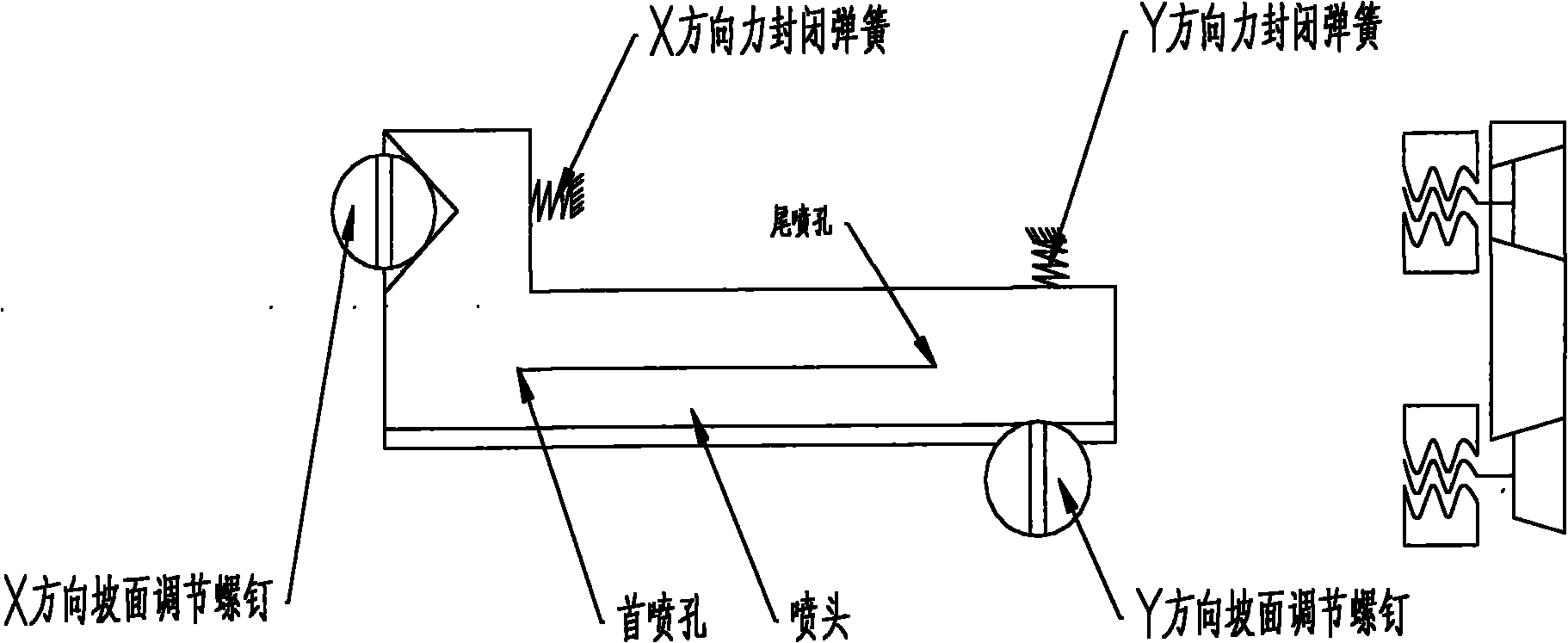

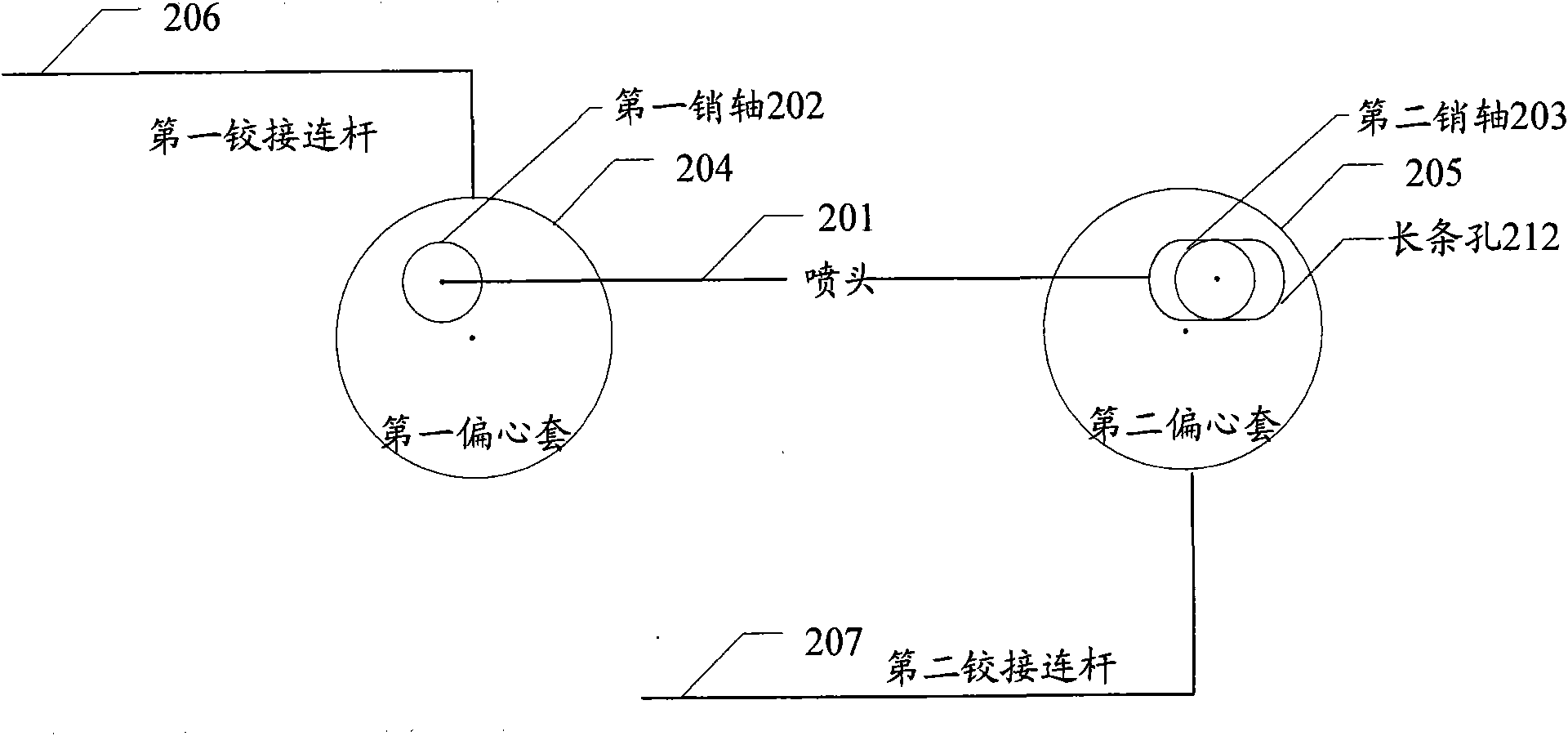

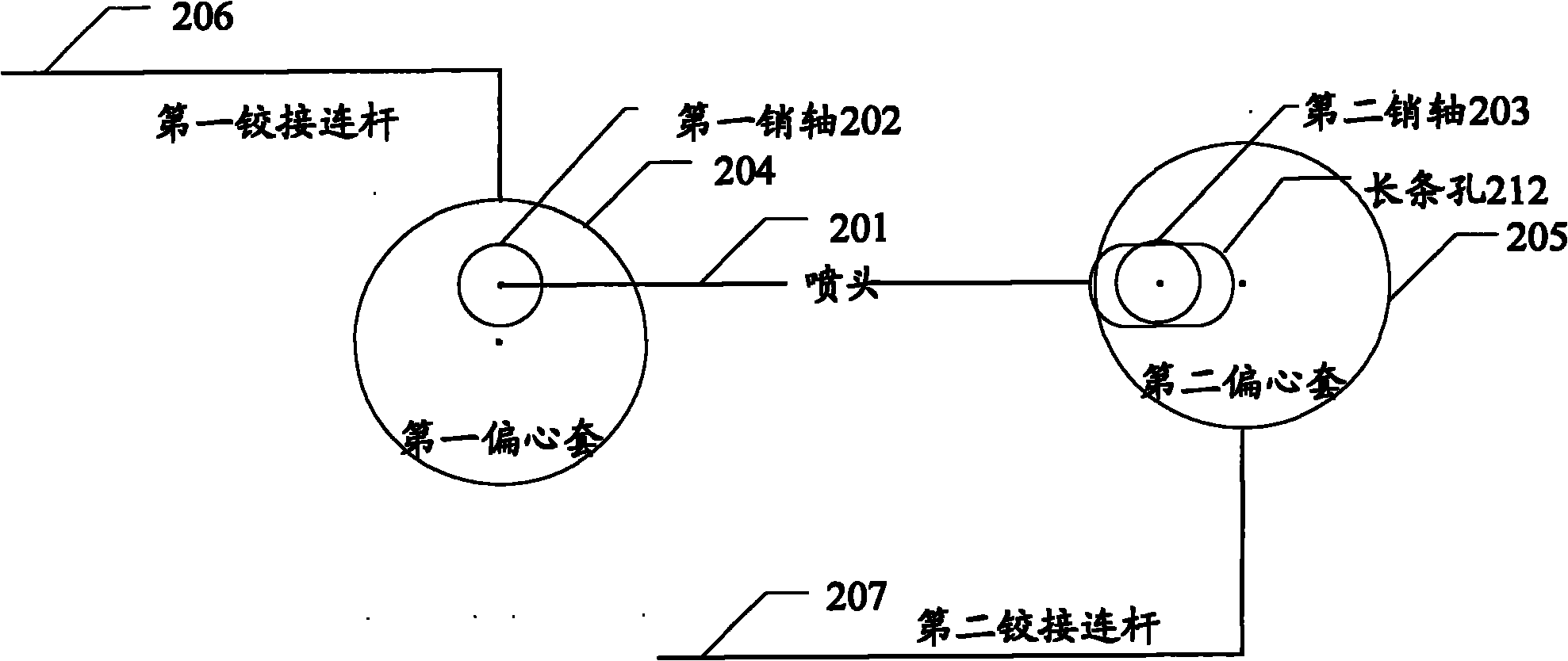

[0019] The adjustment device in this embodiment of the present invention includes: a first eccentric sleeve connected to the first pin shaft, a first hinged link connected to the first eccentric sleeve, a protection component connected to the other end of the spray head, and a second pin connected to the protection component Shaft, the second eccentric sleeve connected with the second pin shaft and the second hinge link connected with the second eccentric sleeve. The hinged connecting rod drives the eccentric sleeve to rotate, the eccentric sleeve drives the pin shaft to rotate, and the pin shaft drives the nozzle to move. Since there is no friction between the hinged connecting rod, the eccentric sleeve, the pin shaft and the nozzle, there is no sliding friction damping, and no crawling phenomenon occurs, thus improving the accuracy of adjustment.

[0020] In this embodiment, the movement of the spray head in the X direction and / or the Y direction is realized through two ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com