Patents

Literature

30results about How to "No crawling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

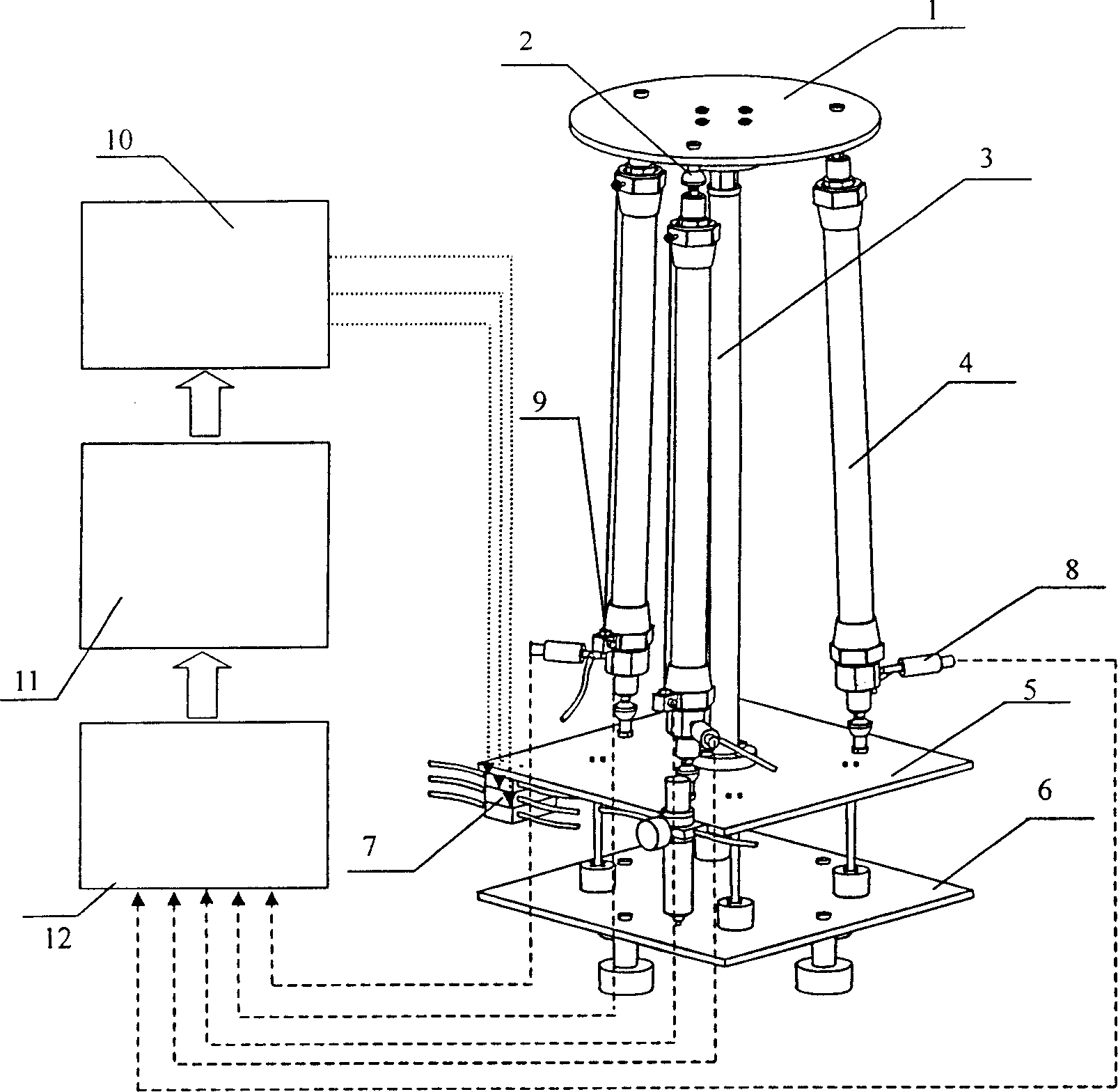

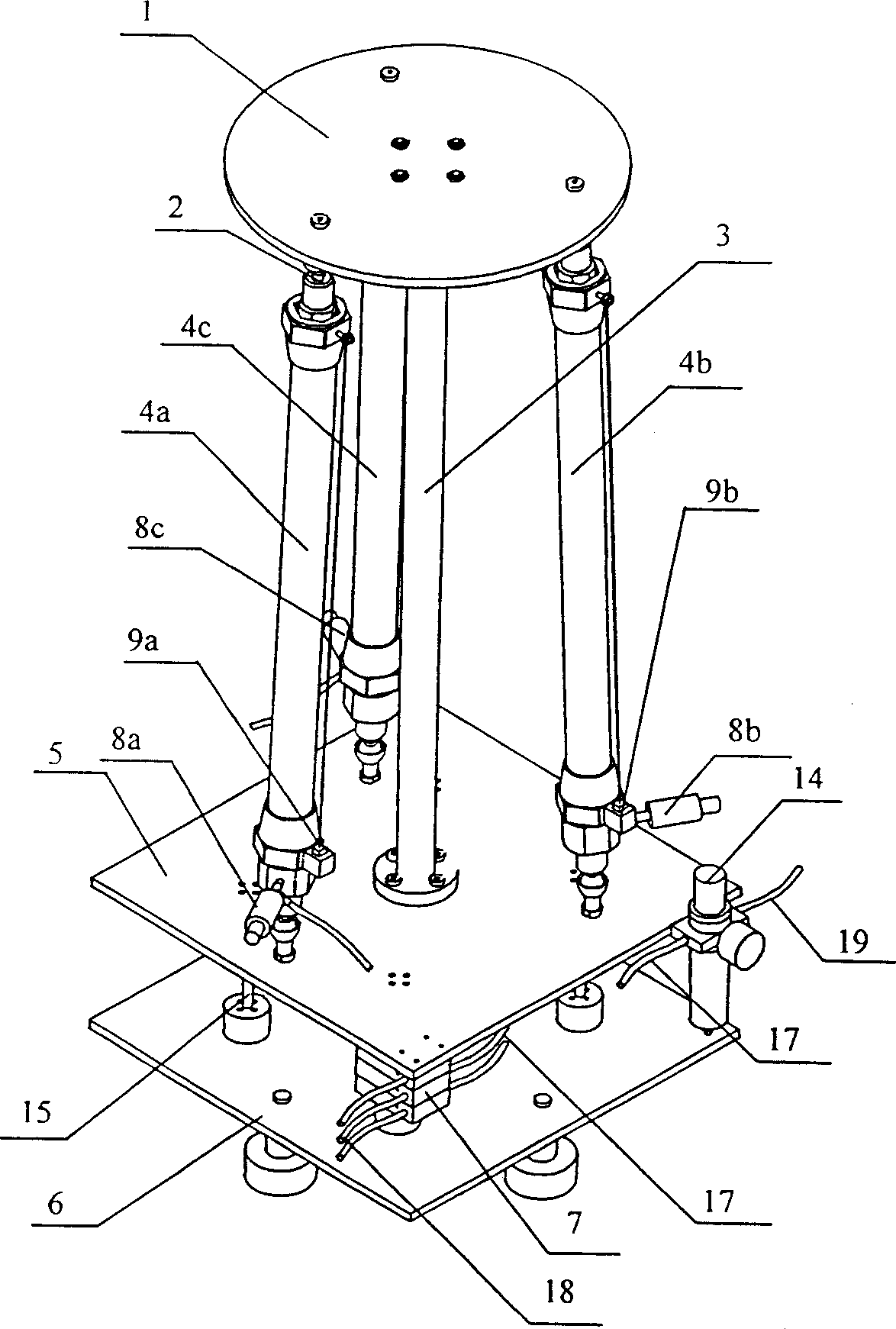

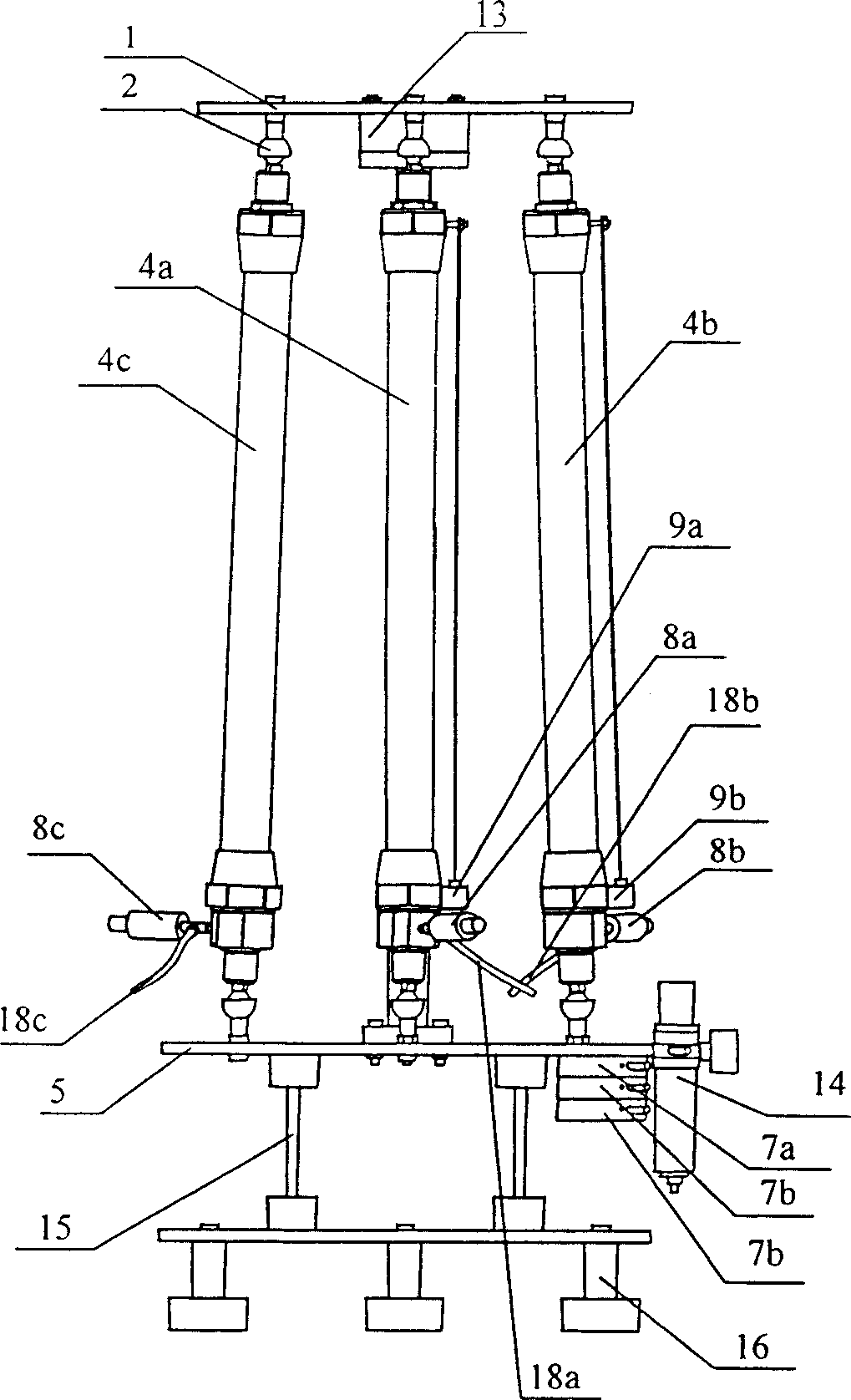

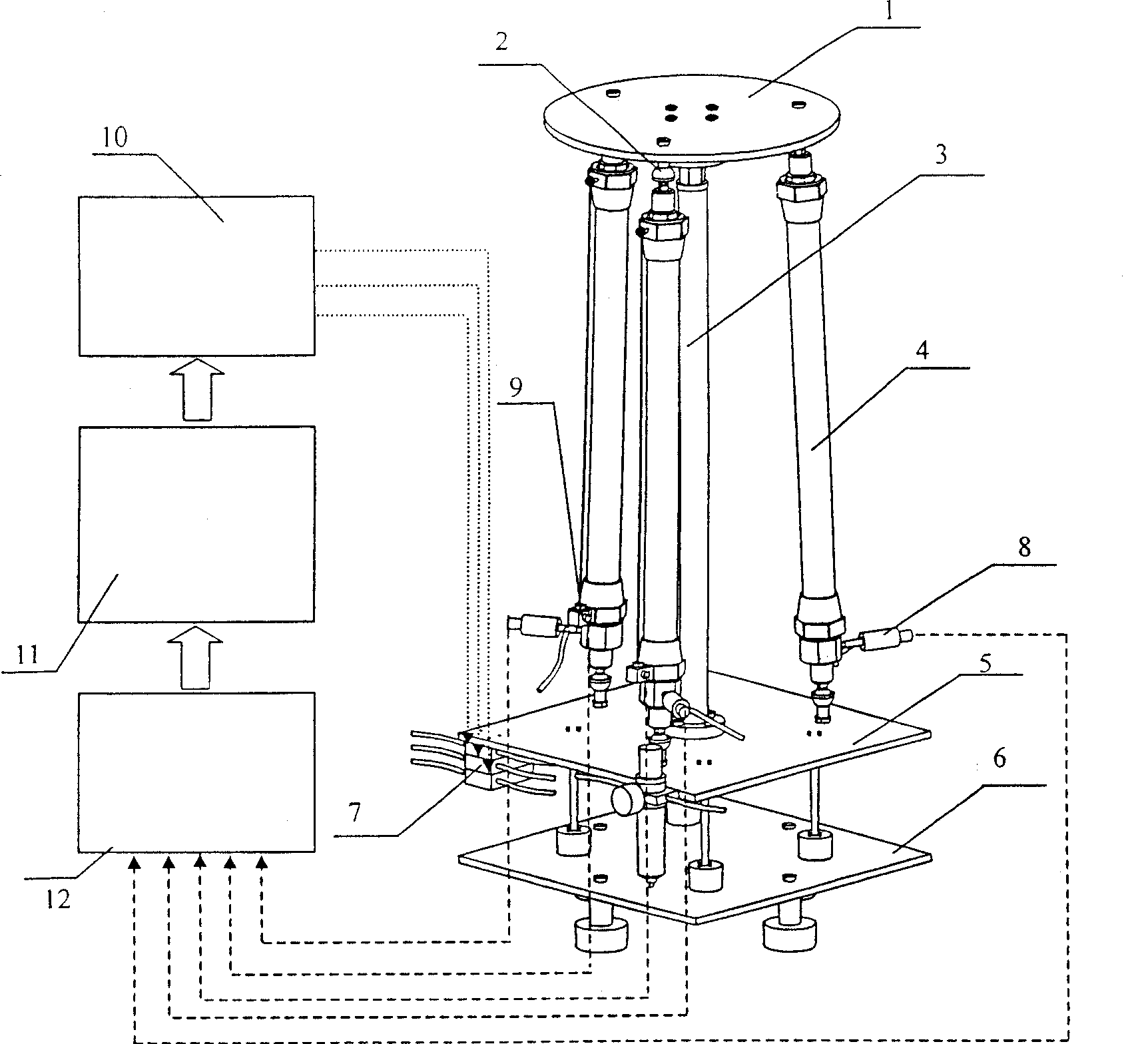

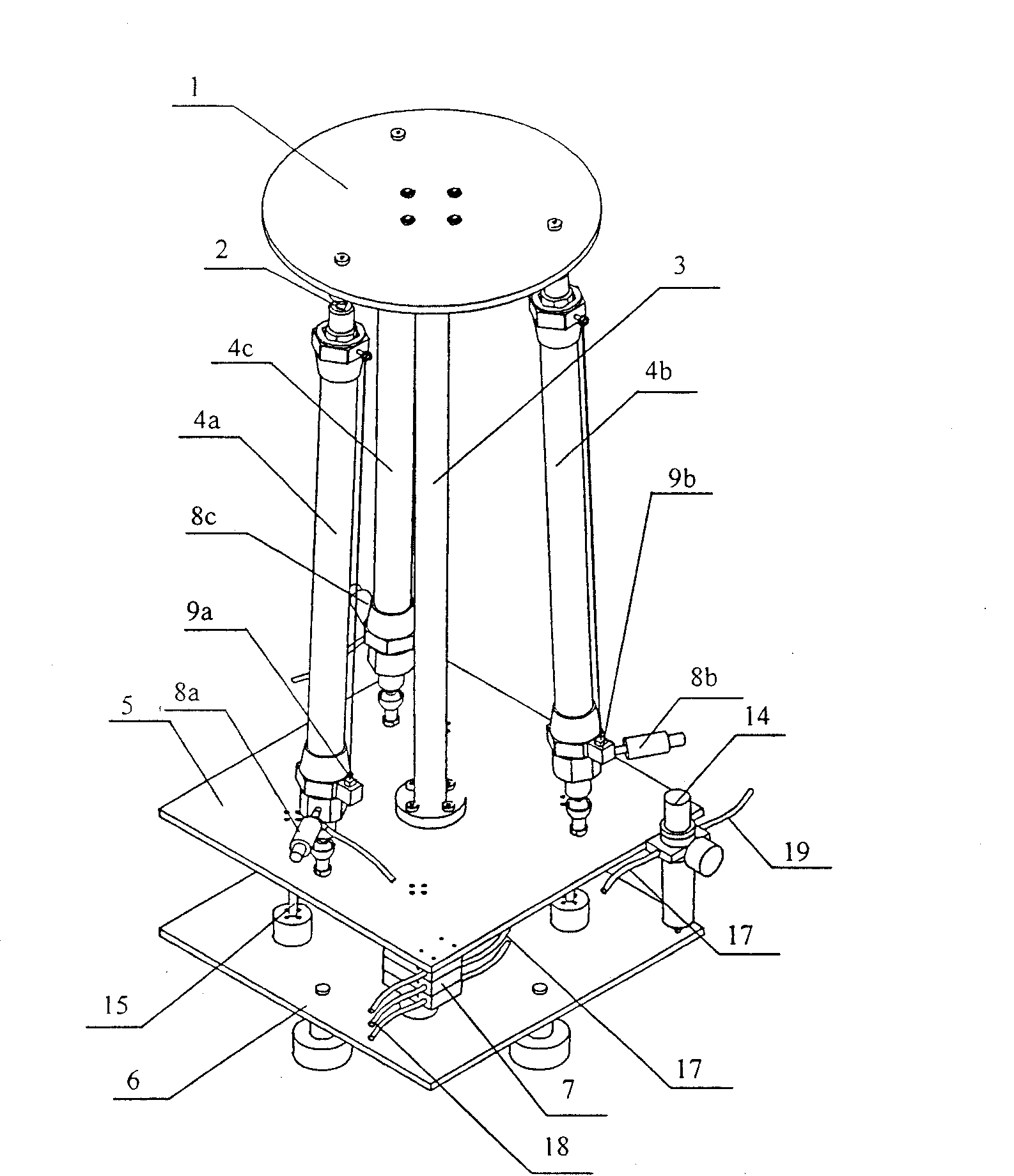

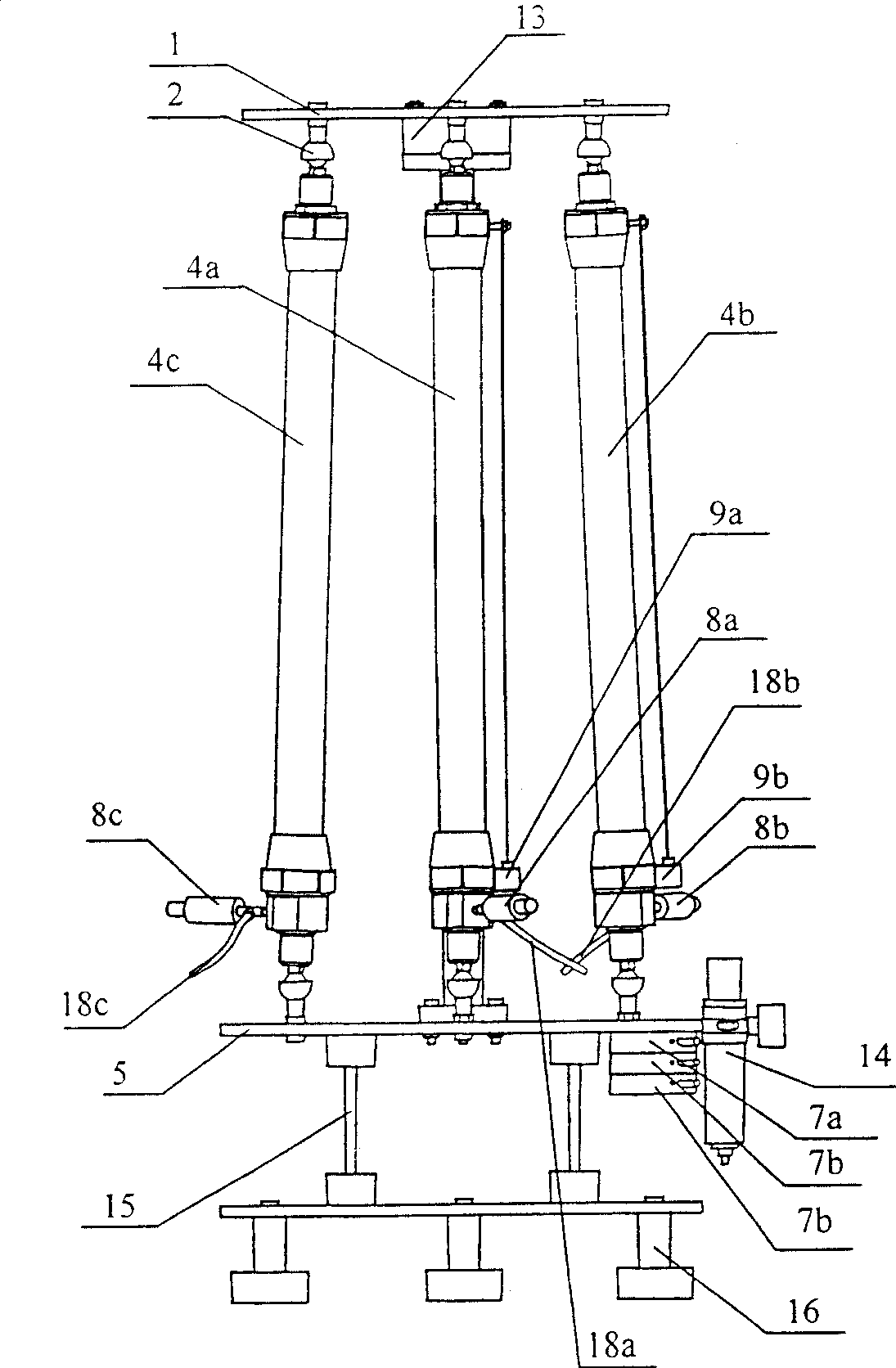

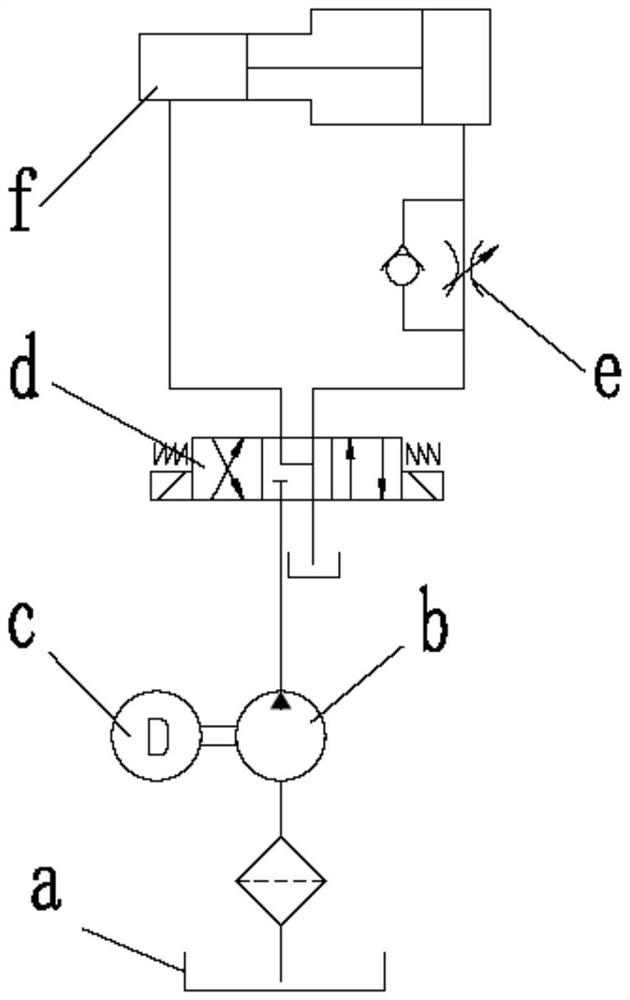

Air-actuated muscle motion analog control platform device and posture control method

InactiveCN1909017AGreat effortReduce volumeCosmonautic condition simulationsAmusementsControl systemComputer module

The disclosed aerodynamic muscle motion simulation control platform comprises: three very same pieces of aerodynamic muscles connected to a central post and a fixed platform, a motion platform hinged to the muscles with uniform-distributed hinge points, and the central post to rigid connect with the fixed platform and hinge the motion platform through a central ball hinge with the hinge point on platform center to endow the motion platform two rotation DOF. Besides, the control system comprises an input conversion module, a controller, and an output drive amplification module. This invention is fit to different motion simulation.

Owner:ZHEJIANG UNIV

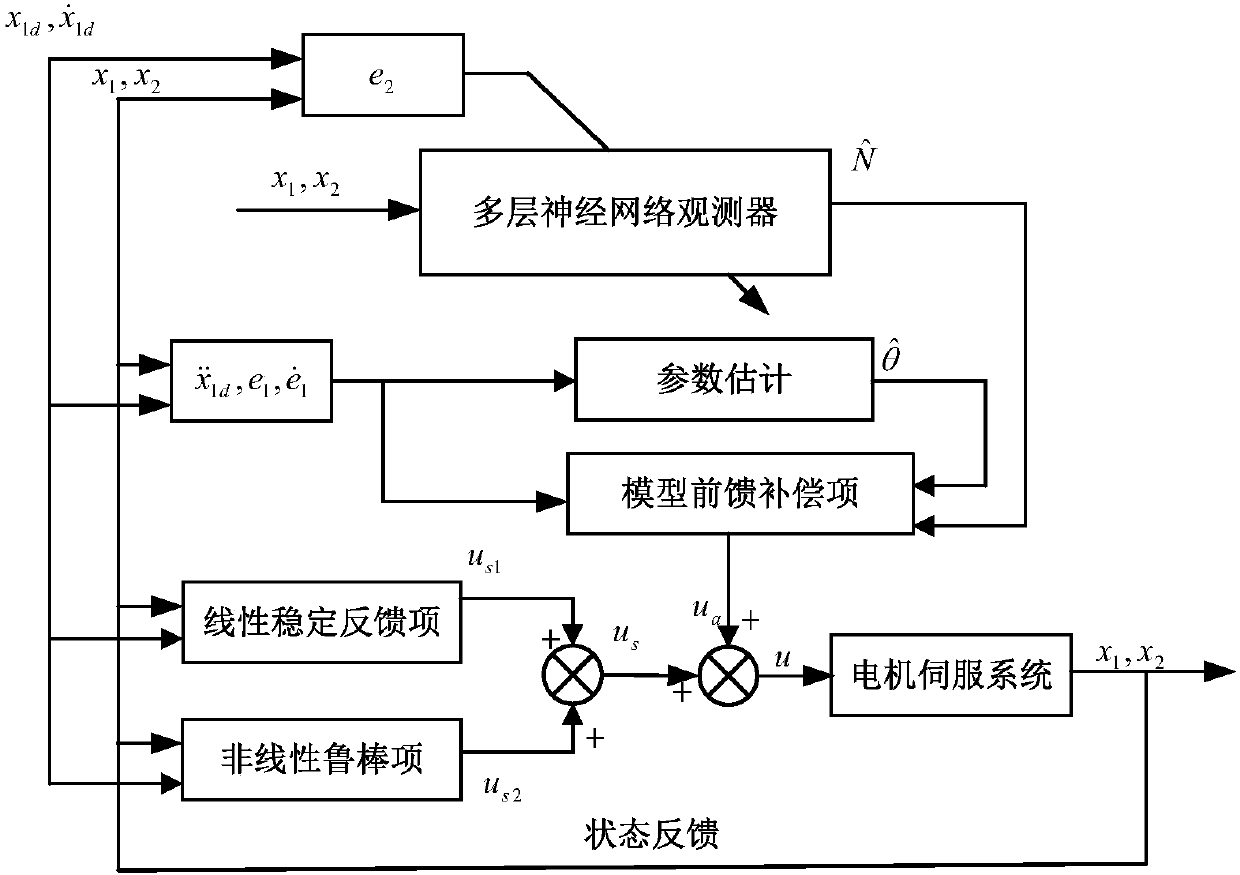

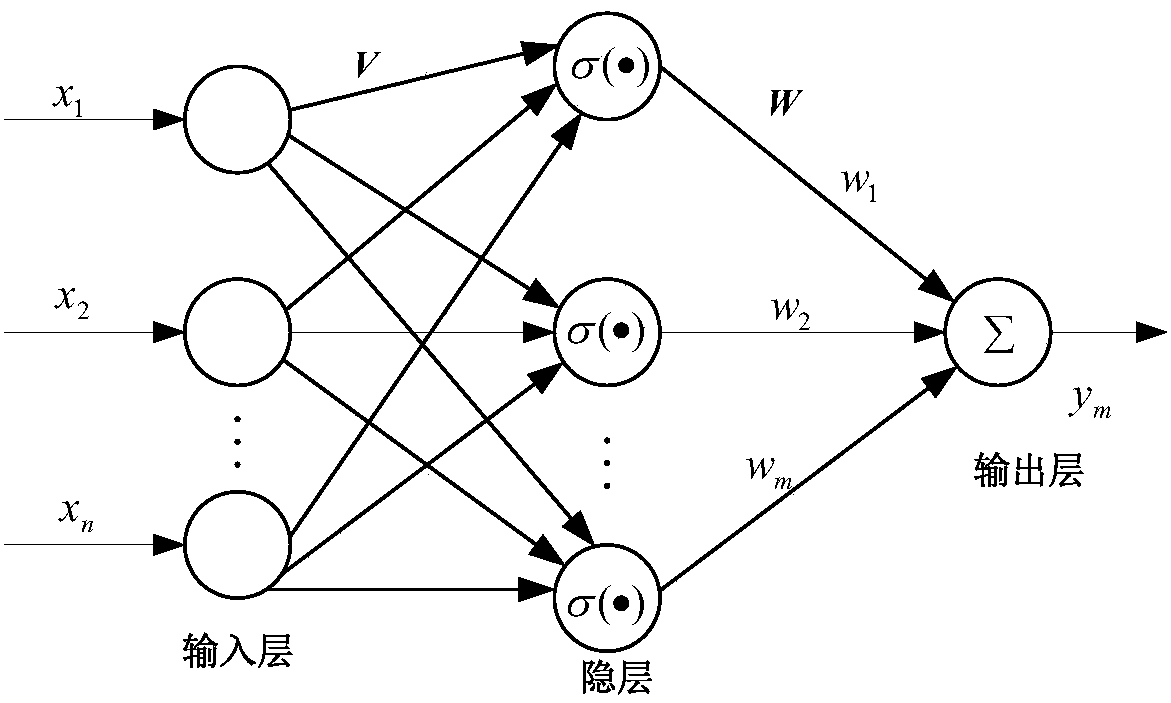

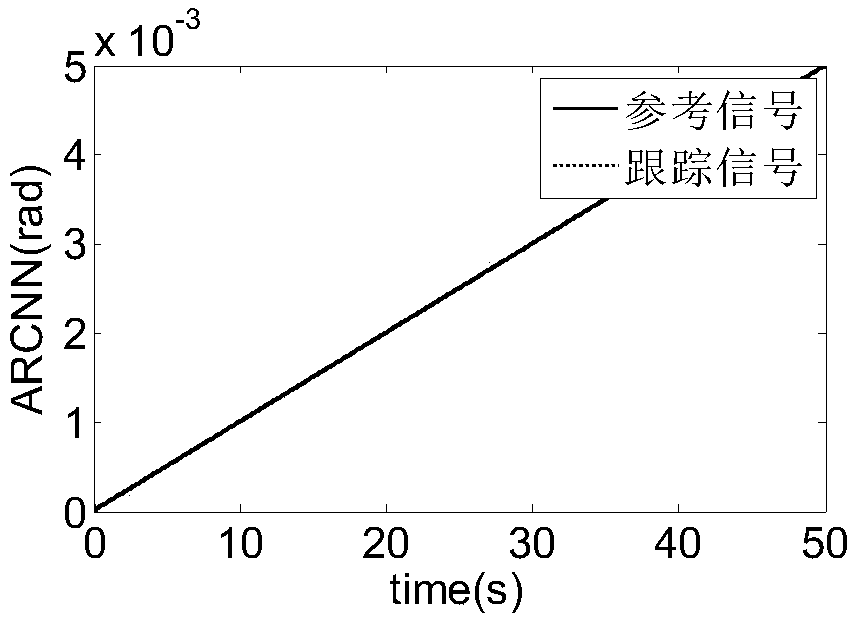

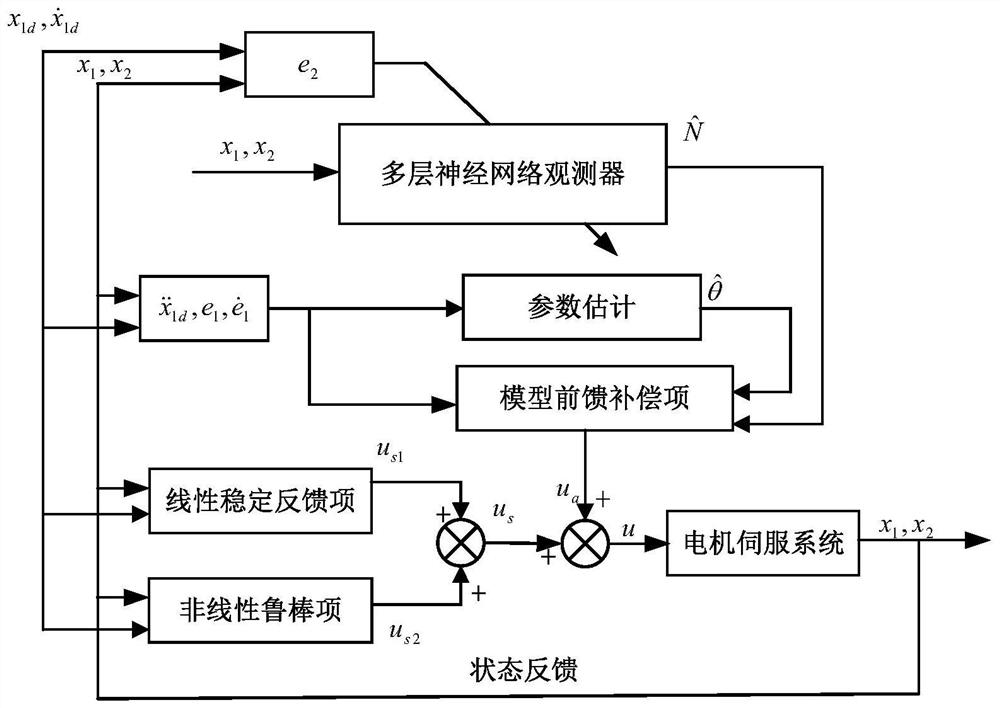

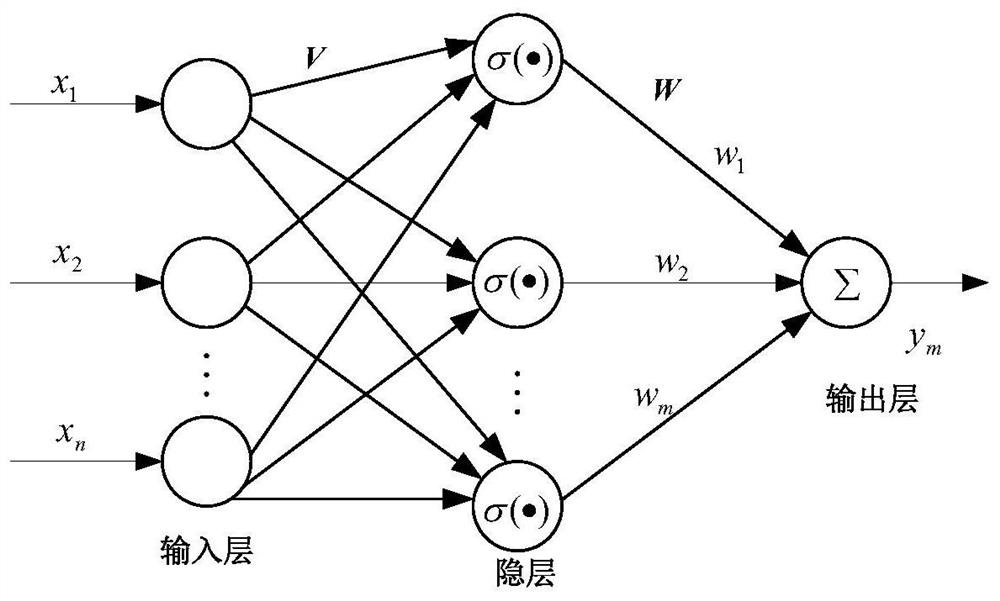

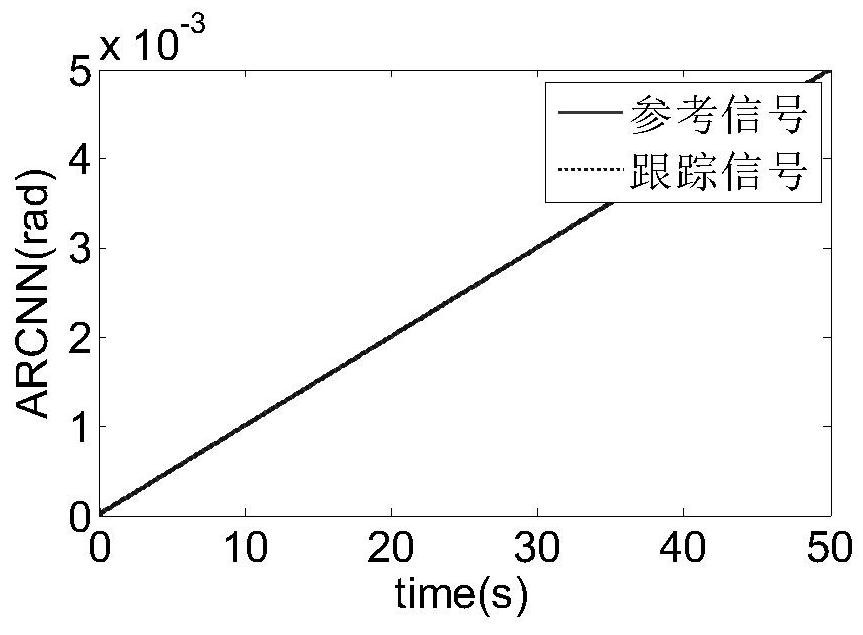

Multilayer neural network-based motor position servo system friction compensation control method

ActiveCN107561935ASolve uncertain nonlinear problems such as nonlinear frictionImprove tracking accuracyAdaptive controlObserver basedControl theory

The present invention discloses a multilayer neural network-based motor position servo system friction compensation control method and belongs to the electromechanical servo control field. According to the friction compensation control method, a neural network and the idea of adaptive robust control are combined, so that a multilayer neural network observer-based adaptive robust controller is designed; and a multilayer neural network is adopted to compensate complex uncertain items in nonlinear friction, and at the same time, an adaptive robust controller is designed to estimate uncertain parameters in a system and compensate external disturbances and the approximation errors of the neural network. With the control method designed by the invention adopted, the nonlinear friction problem ofa motor servo system can be solved, and the excellent tracking performance of the motor servo system can be ensured.

Owner:NANJING UNIV OF SCI & TECH

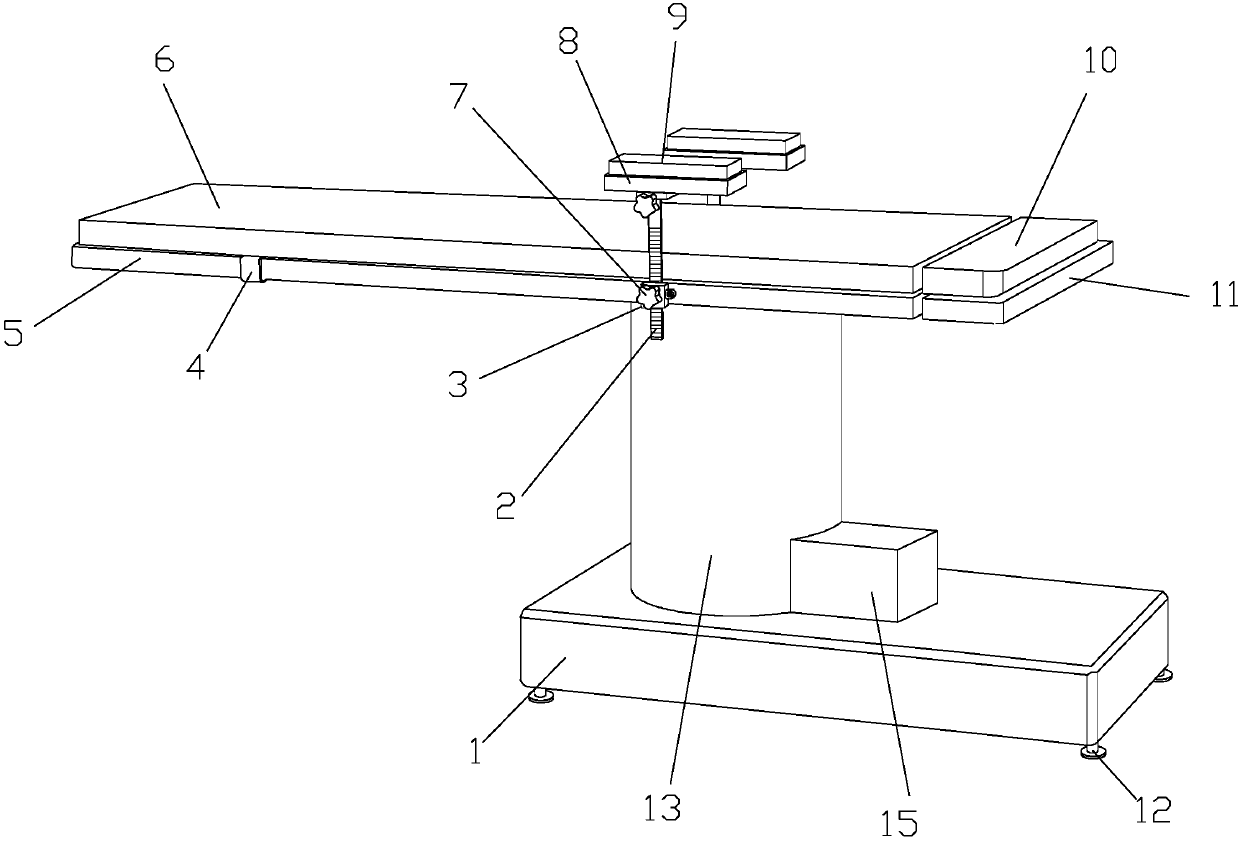

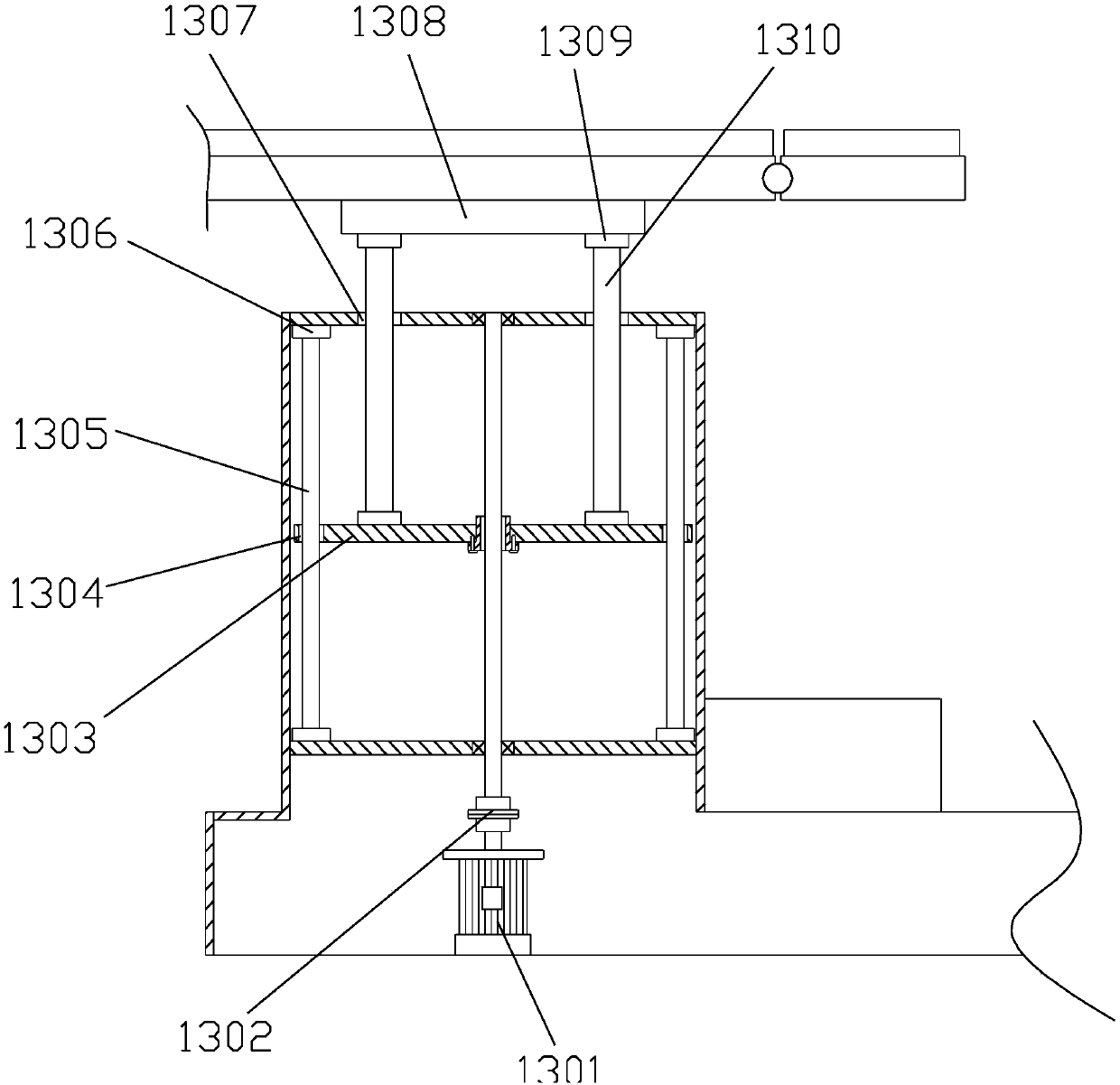

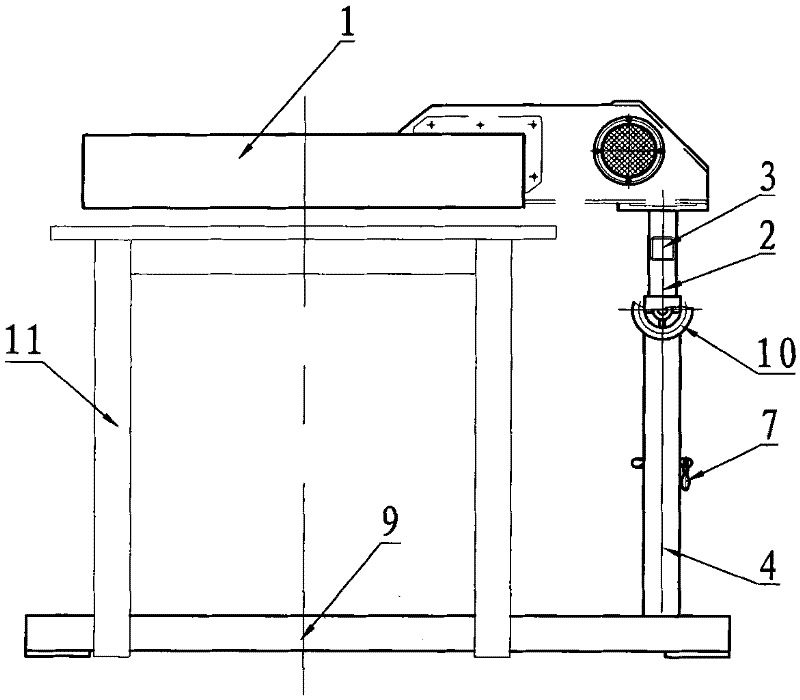

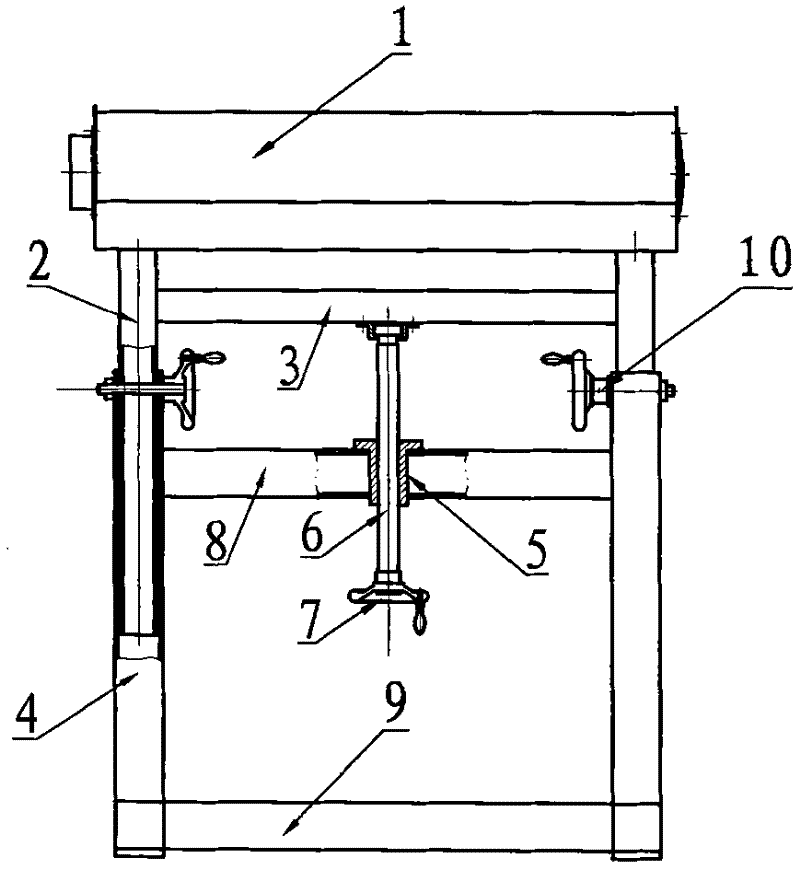

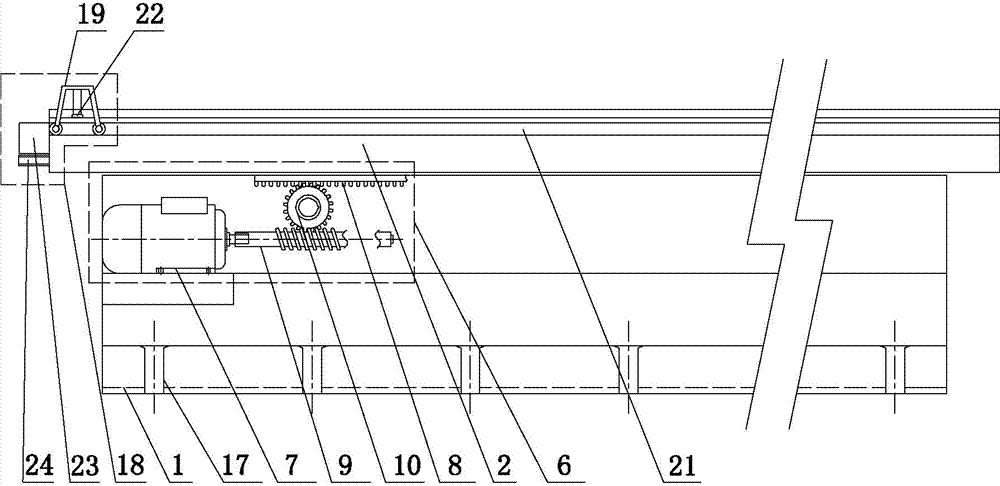

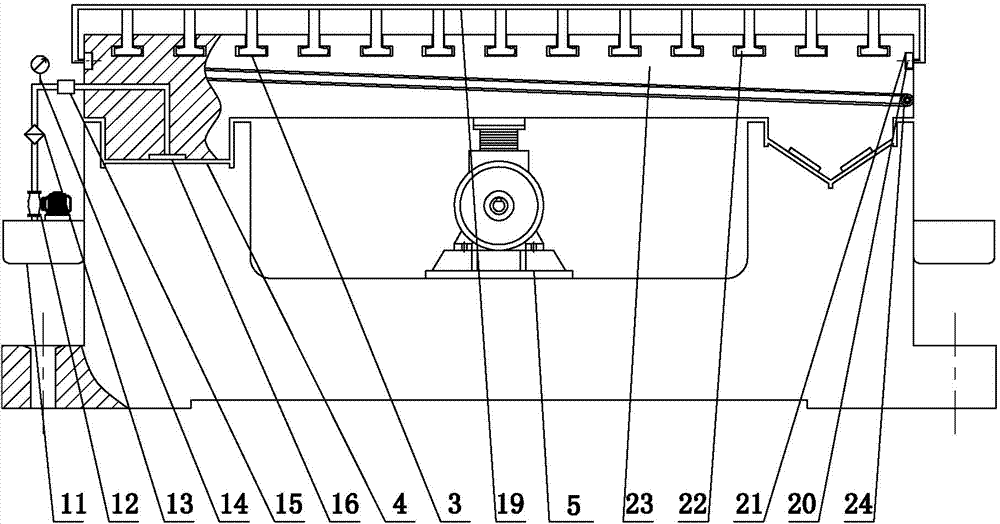

Medical lying bed for examination in ear-nose-throat department

InactiveCN107773376AHigh transmission precisionReduce frictional resistanceOperating tablesAmbulance serviceArm boardsLinear motion

The invention discloses a medical lying bed for examination in ear-nose-throat department. The medical lying bed structurally comprises a base, an ascending and descending rack, a fixing device, a fixing binding belt, a bed plate, a bed plate soft pad, a plum blossom knob screw nut, an arm plate, an arm plate soft pad, a head plate soft pad, a head plate, support foot pads, an ascending and descending device and a first hinge shaft, wherein the support foot pad is vertically arranged on each of the four corners of the bottom of the base in a screw bolt connection mode. The medical lying bed for examination in ear-nose-throat department has the advantages that the ascending and descending device is arranged inside the base; a step motor and a lead screw are used in a matched way for controlling the ascending and descending of the examination lying bed; the rotating movement is converted into the linear movement; the lead screw transmission precision is high; the friction resistance is very small; the creeping phenomenon of sliding movement cannot occur; the precise micro feeding is enabled to be realized; the rotation of the step motor is the operation step by step at the fixed angle, so that the accurate positioning goal is achieved; uncomfortable feeling cannot be caused on the patient; meanwhile, the rotation of the lying bed can be controlled through a second step motor.

Owner:张祝萍

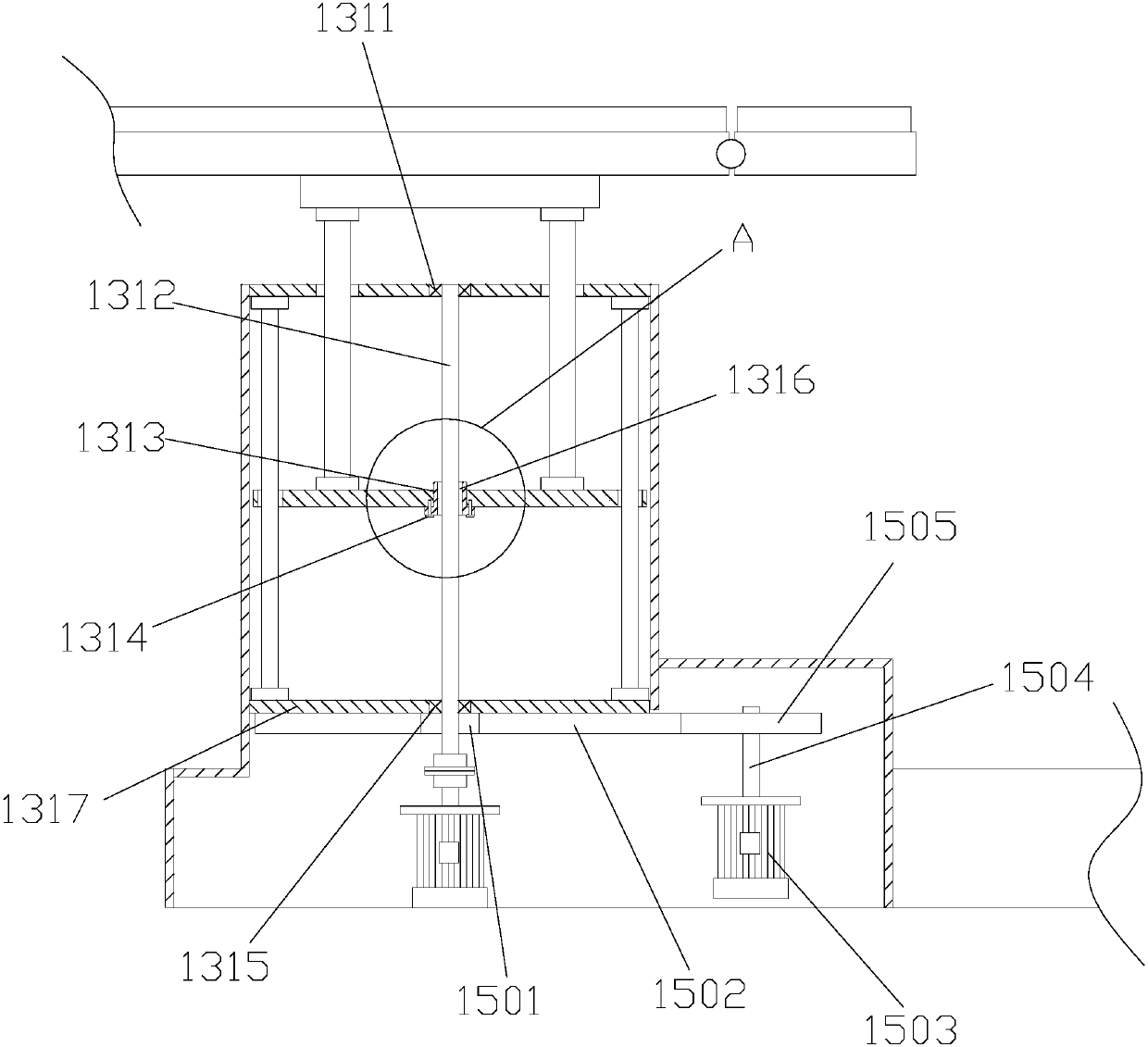

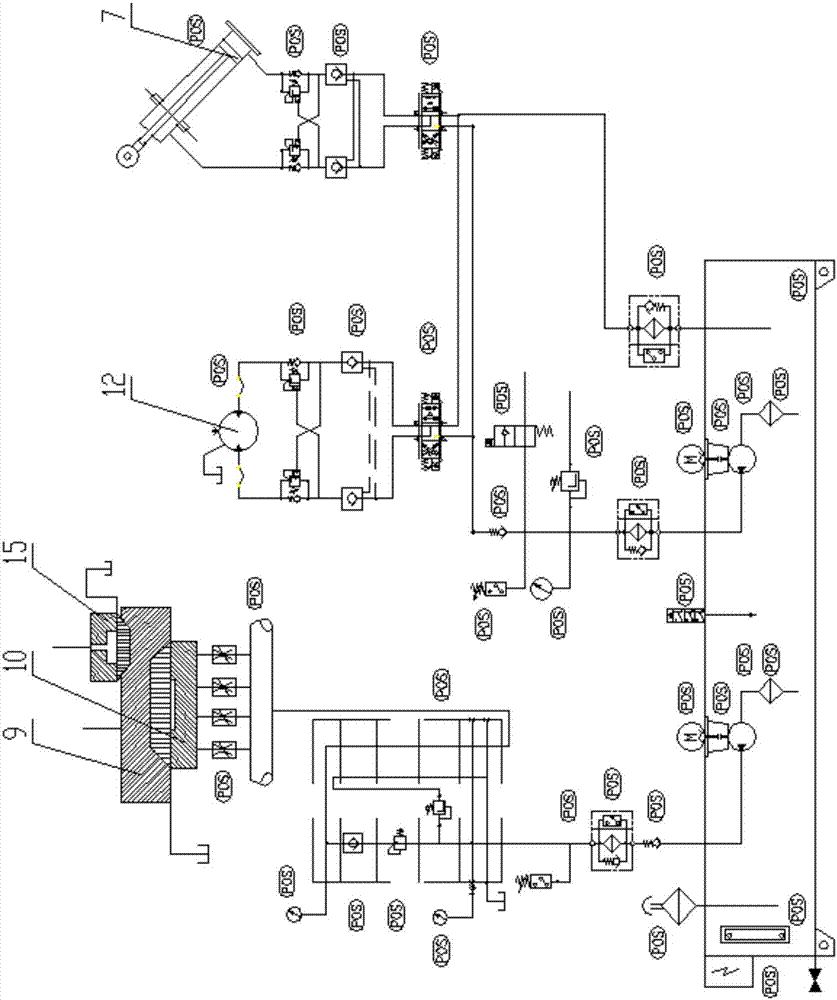

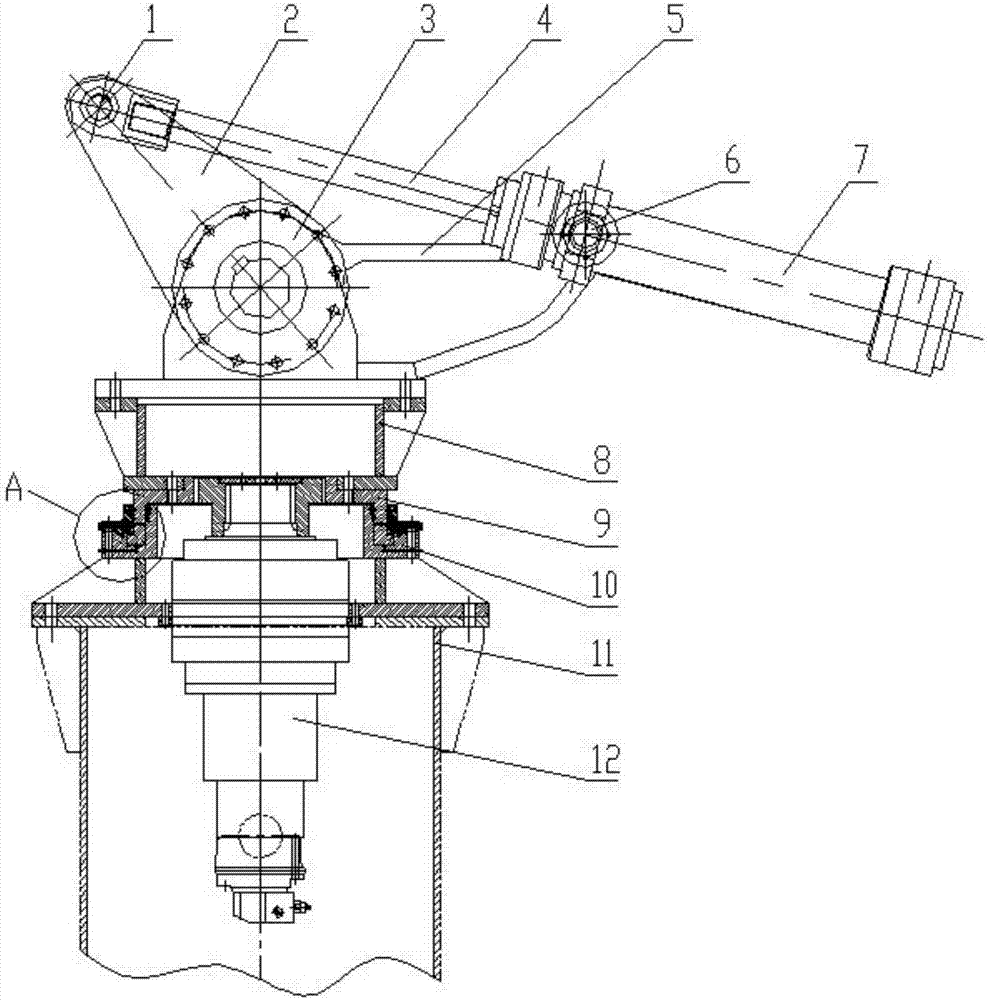

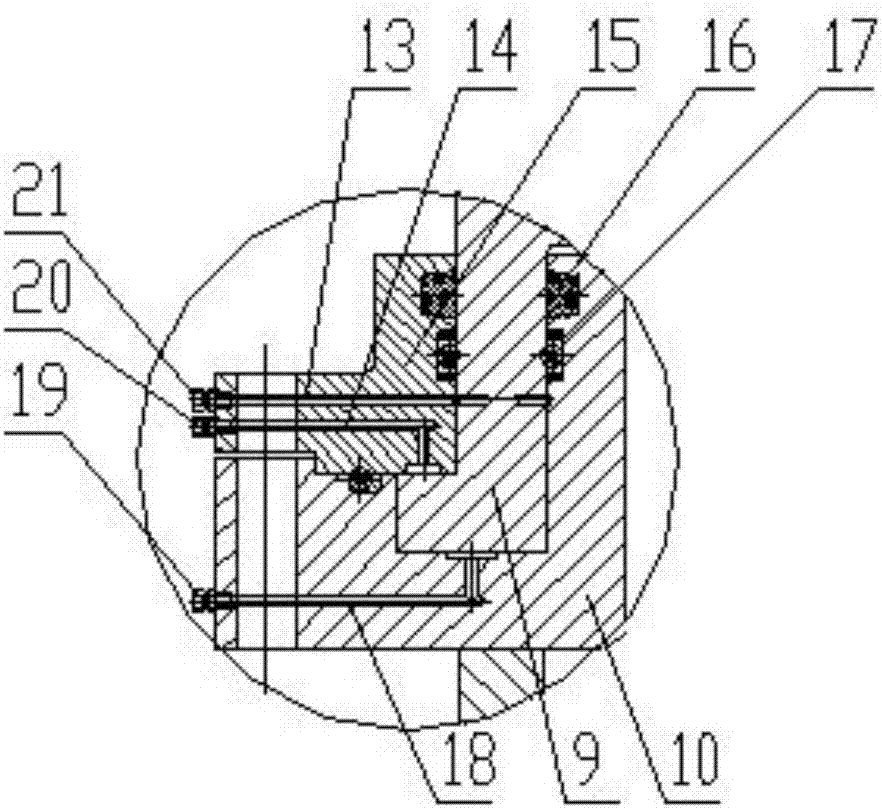

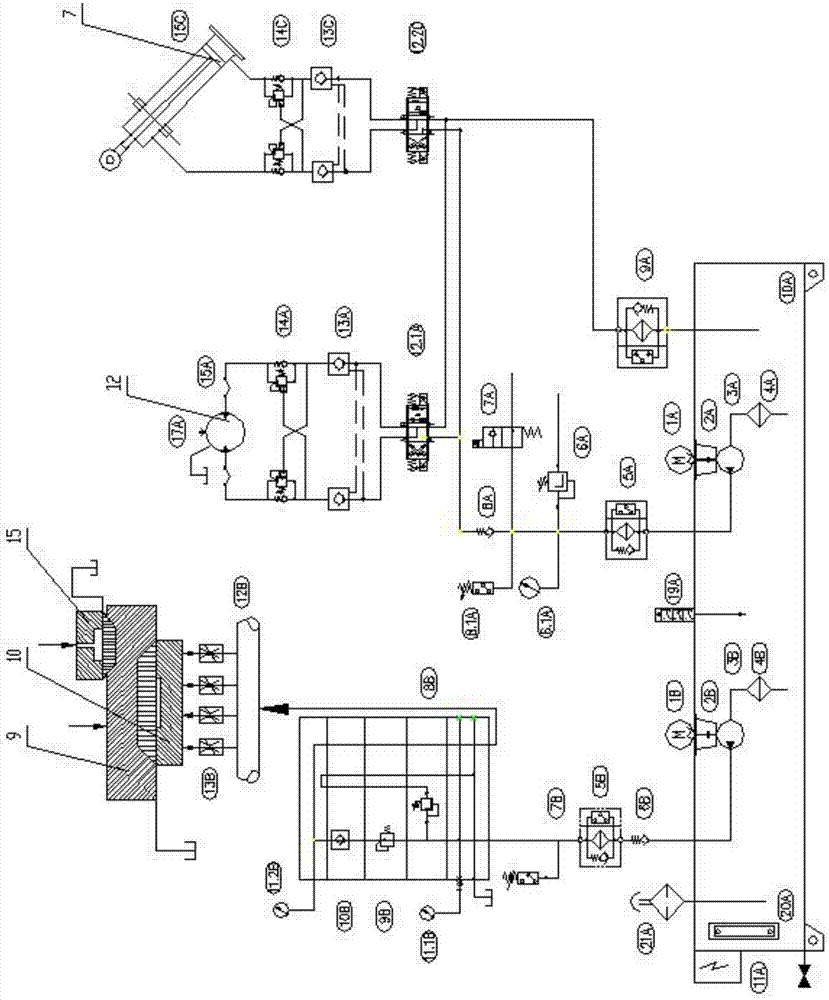

Azimuth rotation static-pressure support system of tower solar thermal power generation heliostat

ActiveCN106949106ASmall turning torqueLow costServomotor componentsServomotorsSupporting systemHydraulic motor

The invention relates to an azimuth rotation static-pressure support system of a tower solar thermal power generation heliostat. The tower solar thermal power generation heliostat includes a tower frame, a hydraulic motor speed reducer, an azimuth rotating unit and a pitching motion unit. The system designs chute and slide ring structures, and injects oil to the lower bottom end surface of a slide ring and the upper flat end surface of a chute through a pressure reducing valve, a one-way valve and a capillary throttling valve, so that the lubricating performance is greatly improved, the rotating torque of the tower heliostat azimuth is reduced by 70% compared with the torque of a mechanical drive, the azimuth rotation driving torque is largely reduced, the sizes of the driving device and the hydraulic motor are both largely reduced, and the cost of the azimuth driving device is correspondingly reduced.

Owner:TIANJIN OULU HEAVY MACHINERY MFG

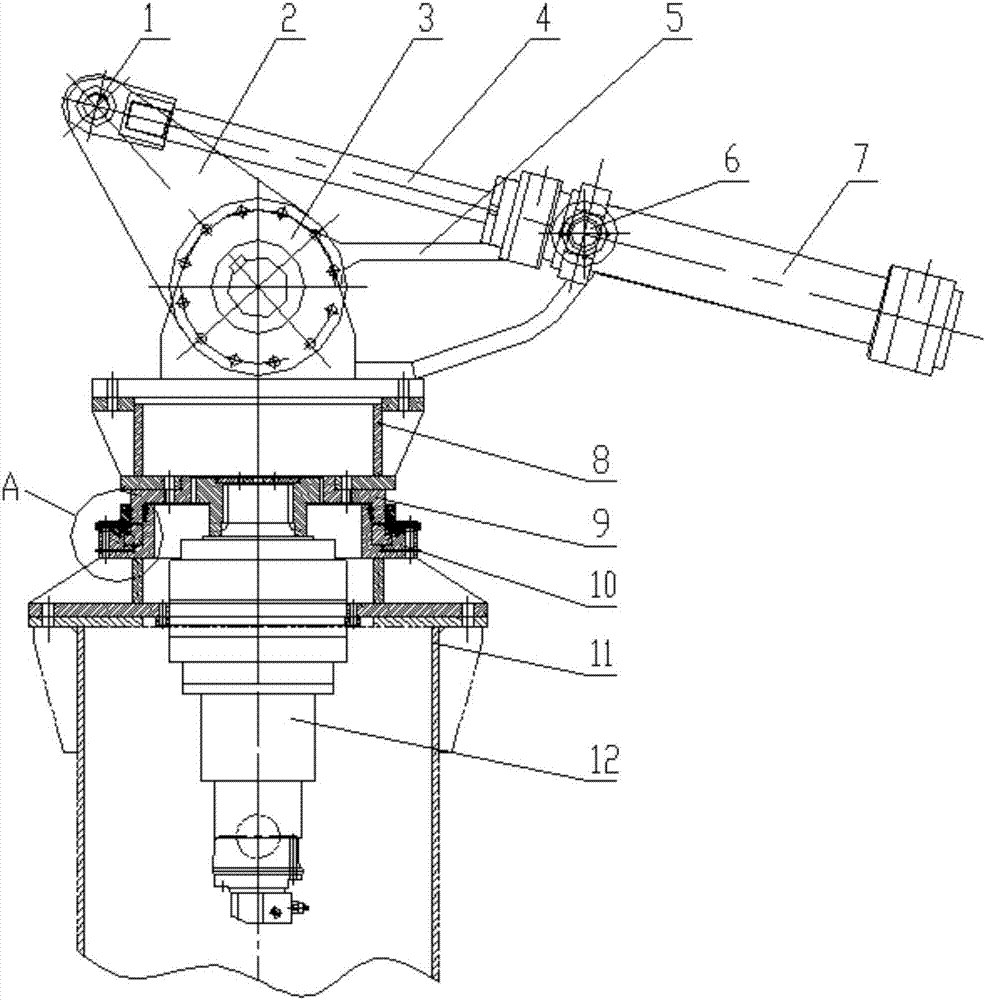

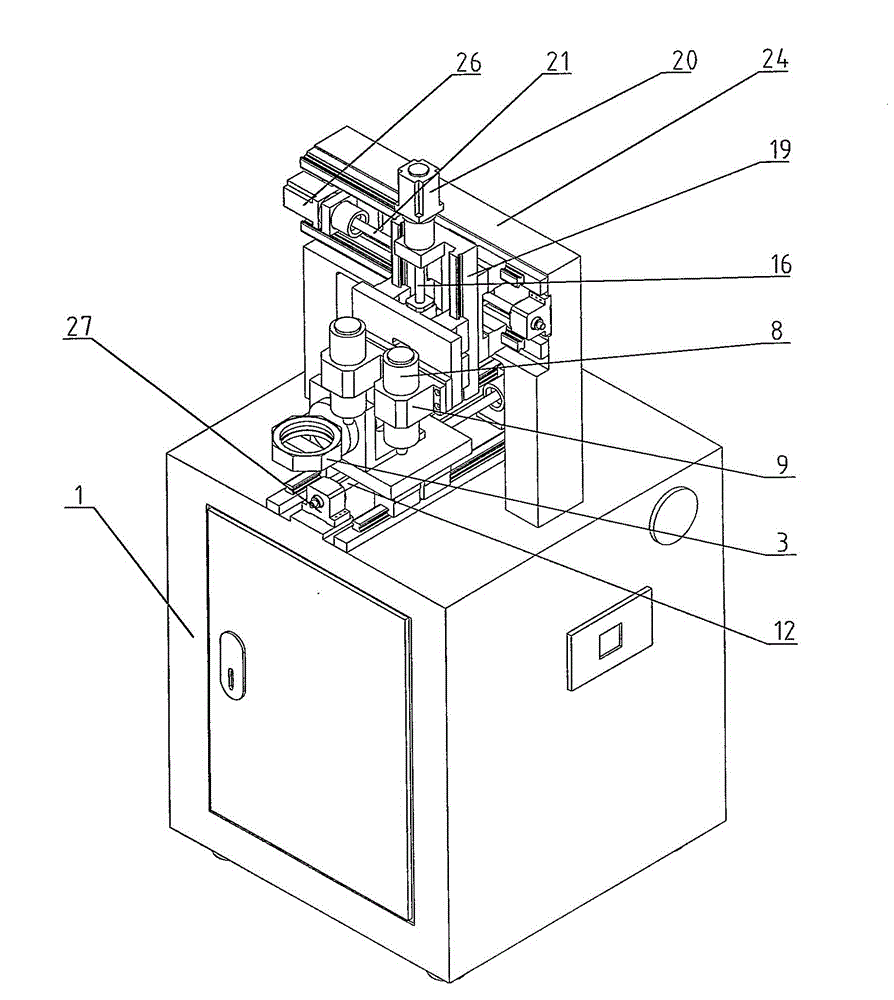

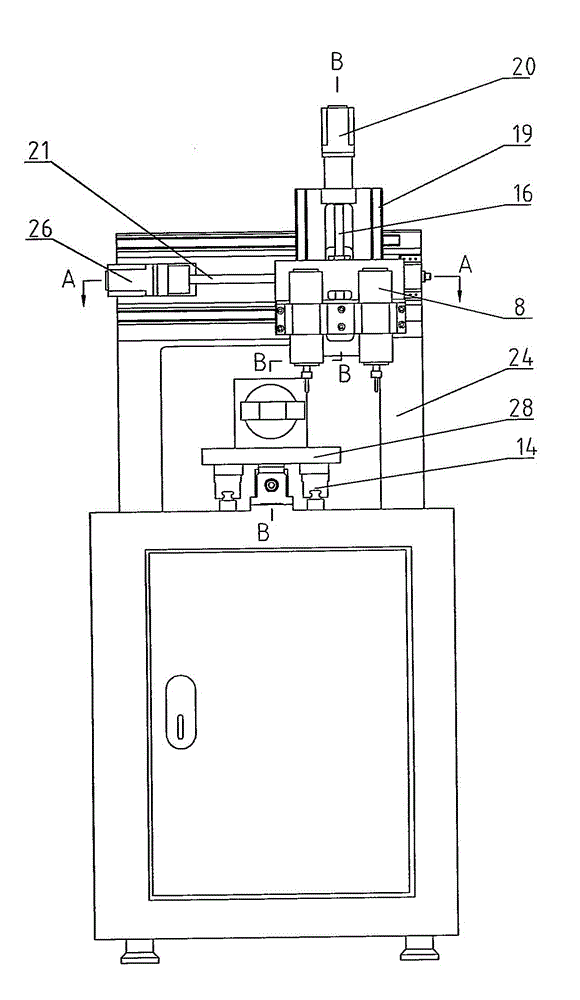

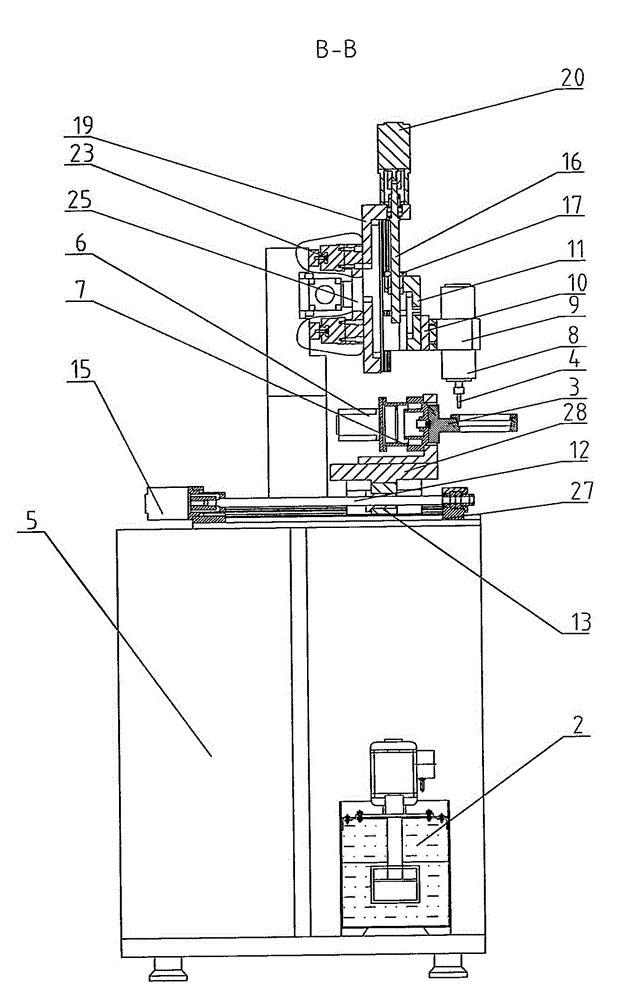

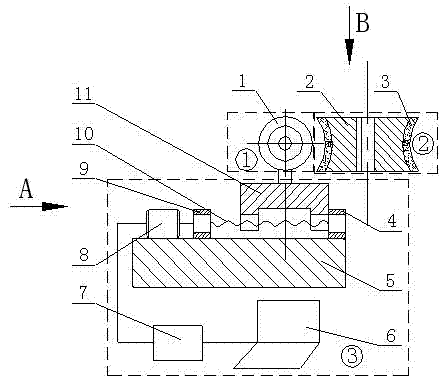

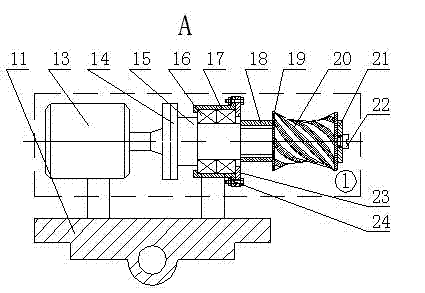

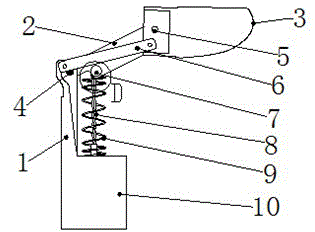

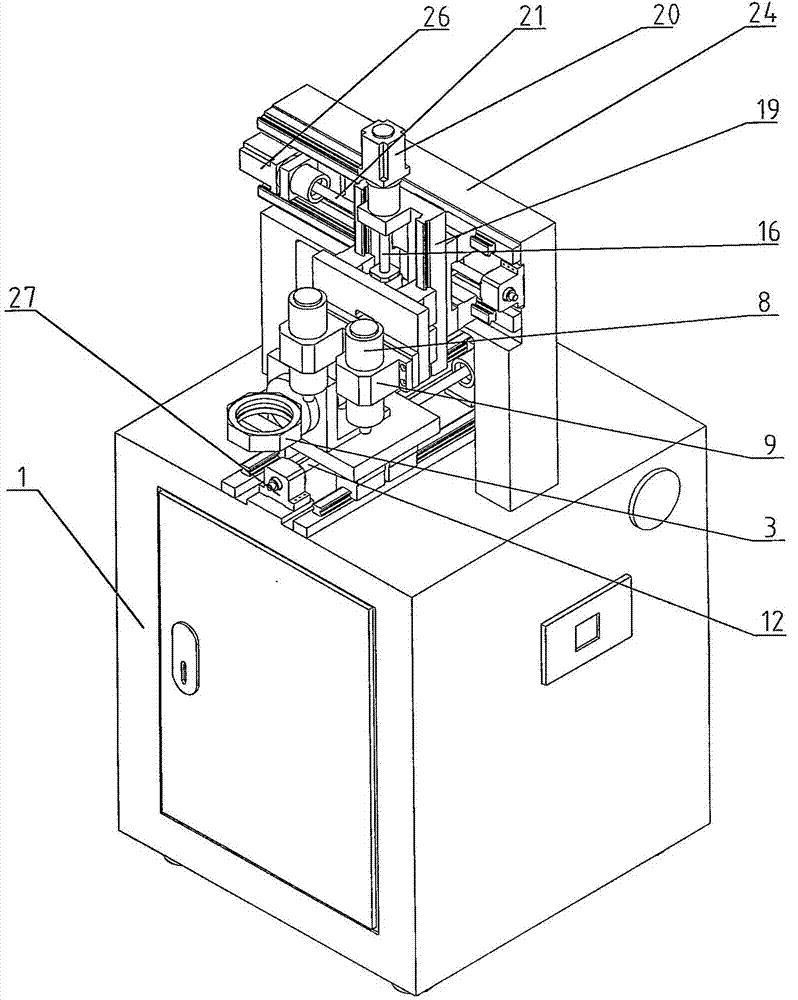

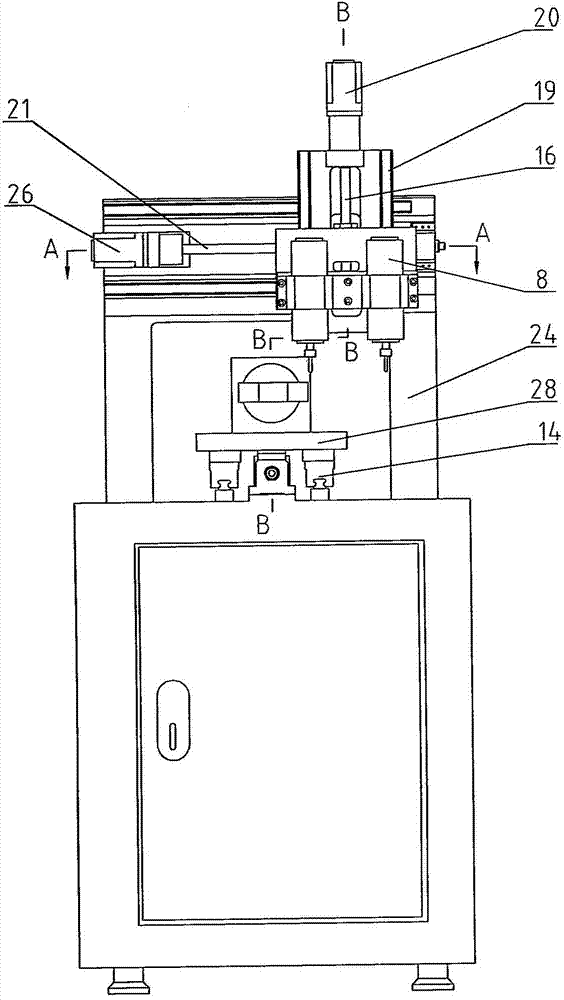

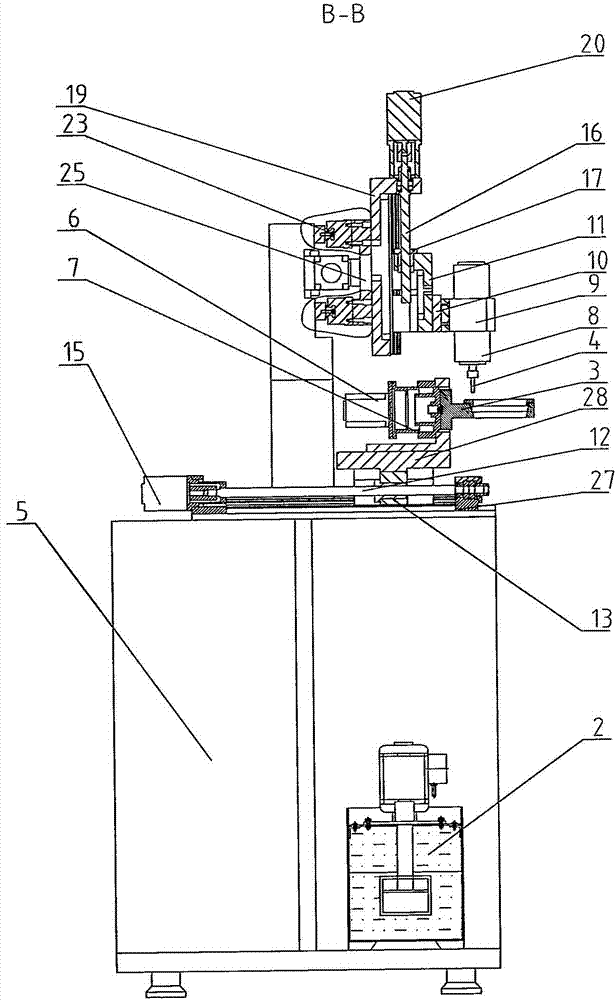

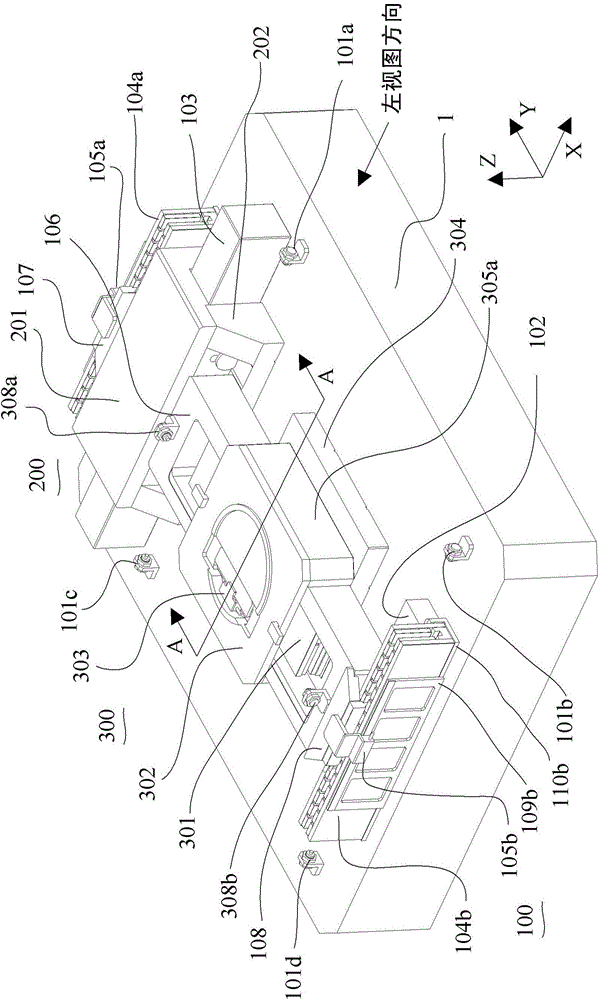

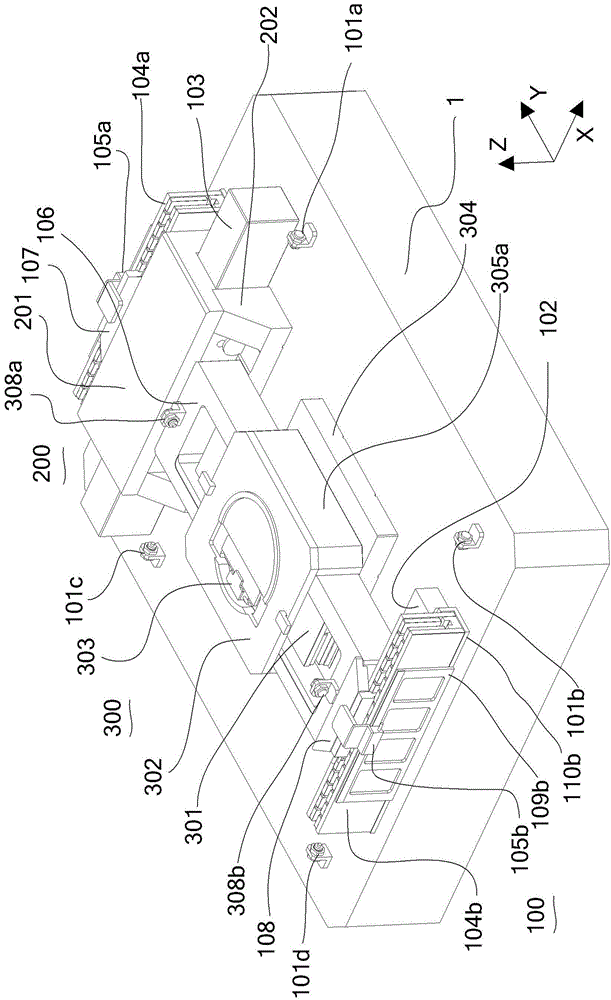

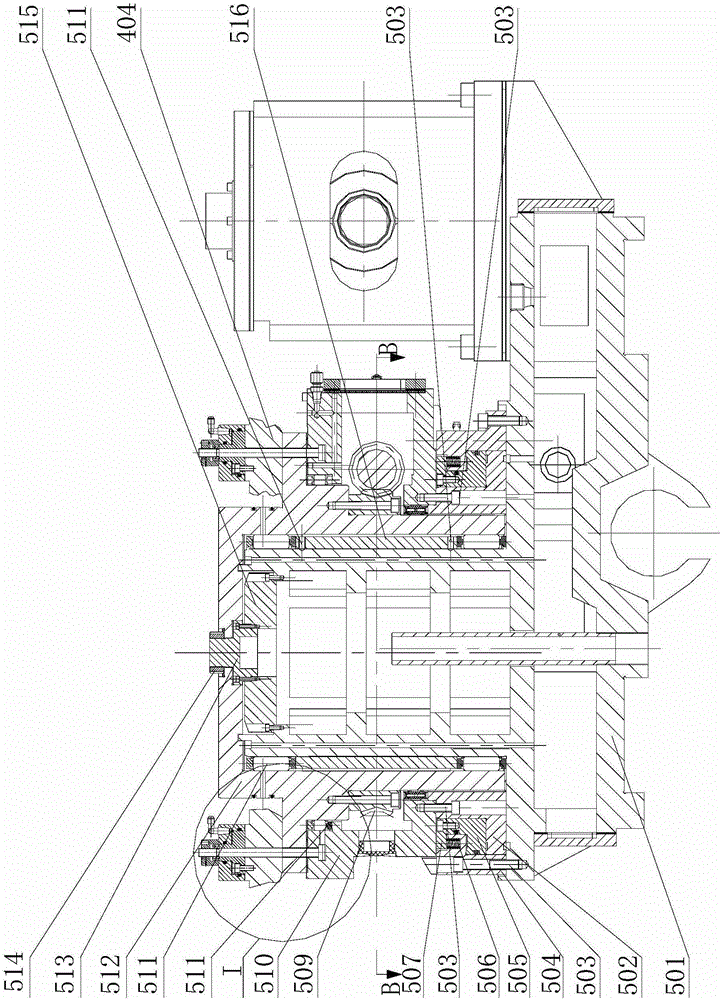

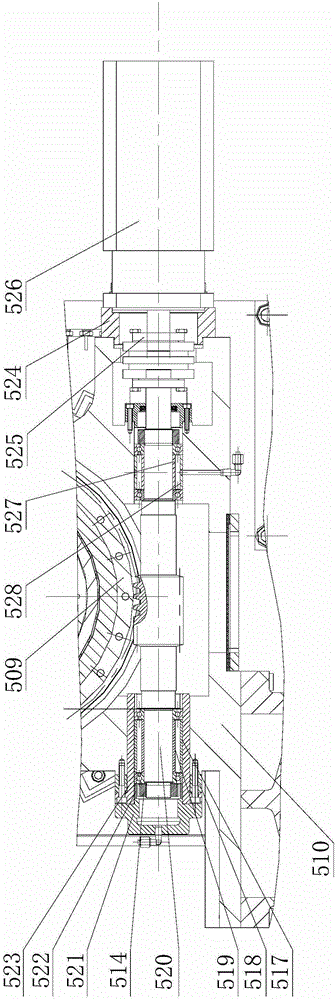

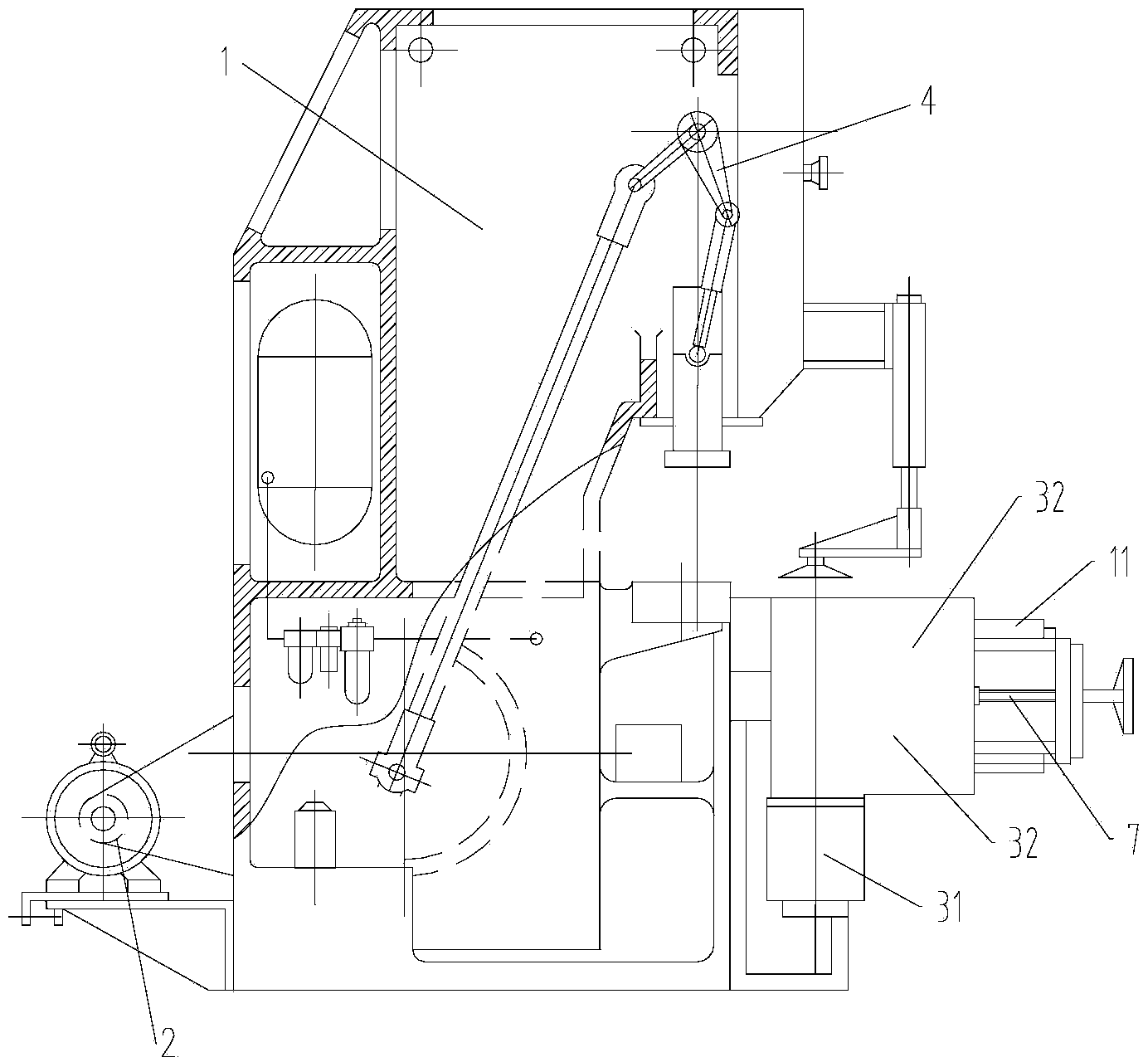

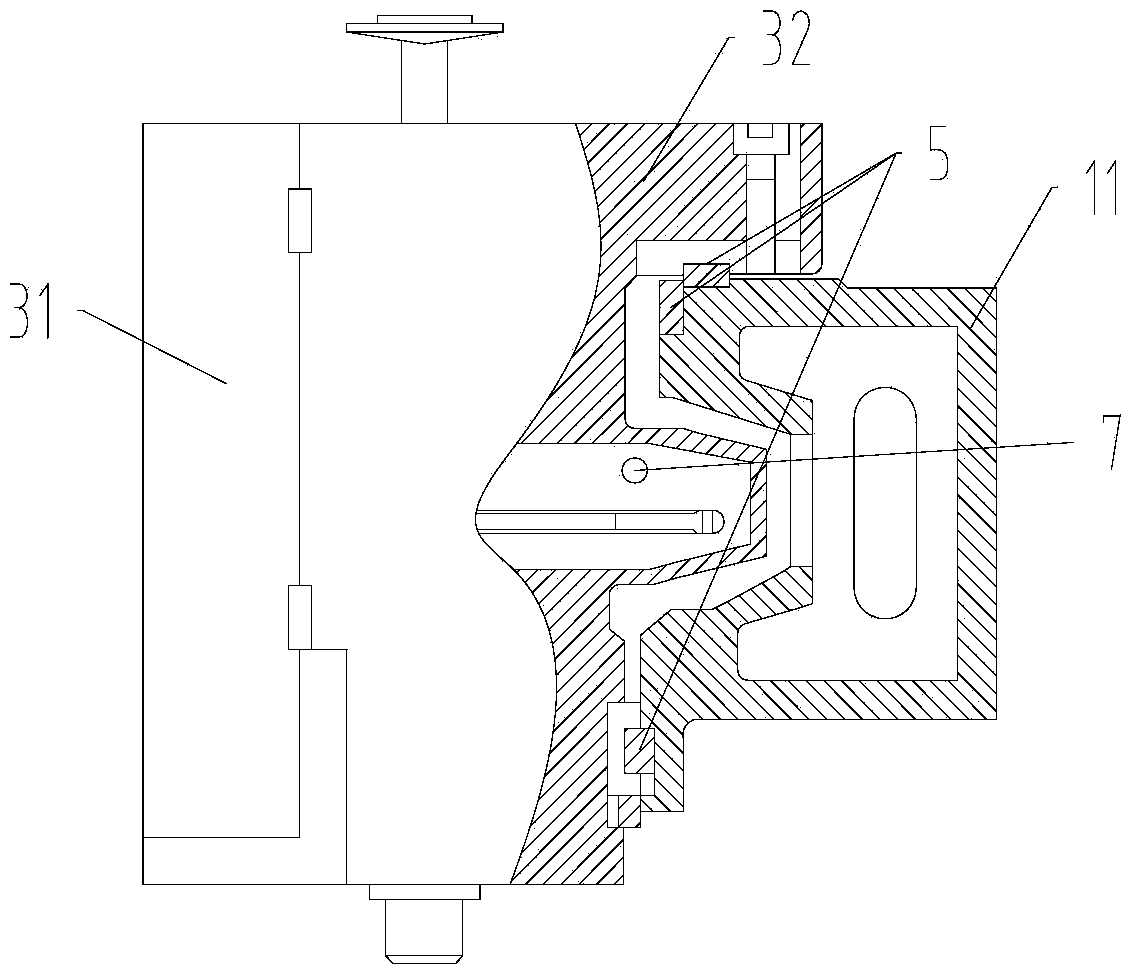

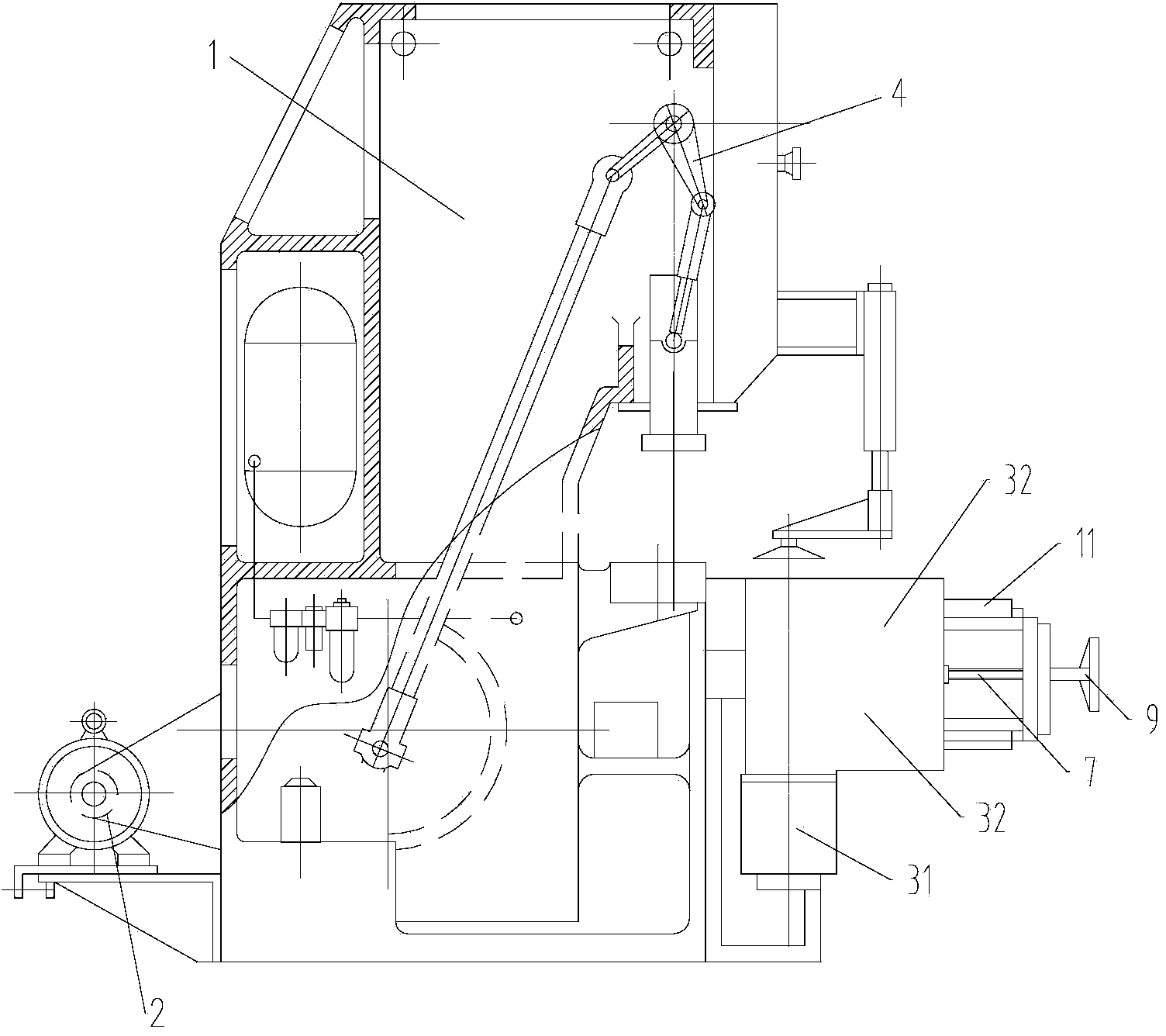

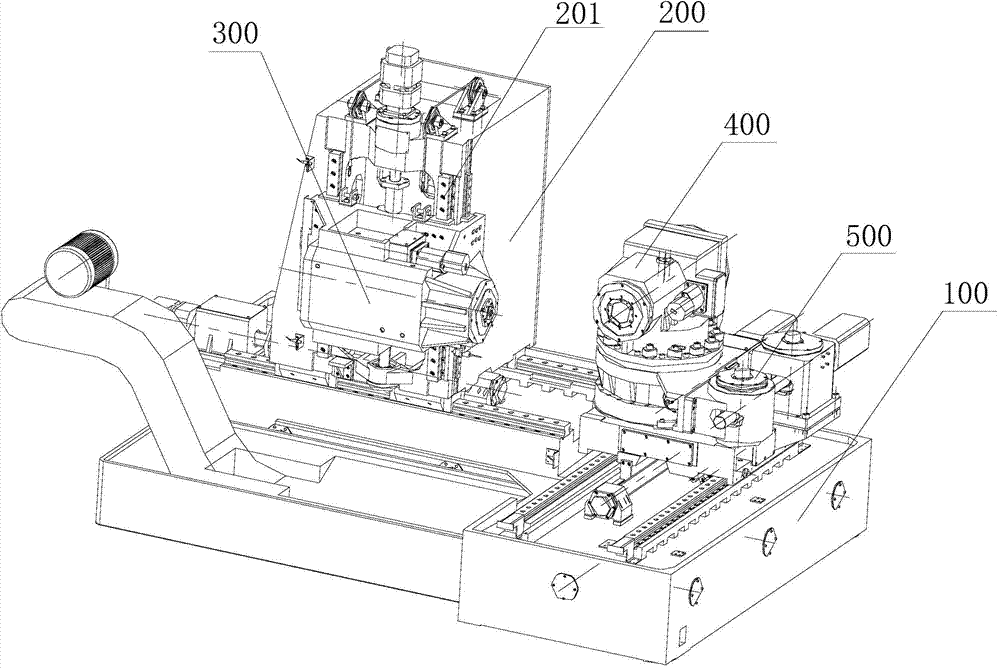

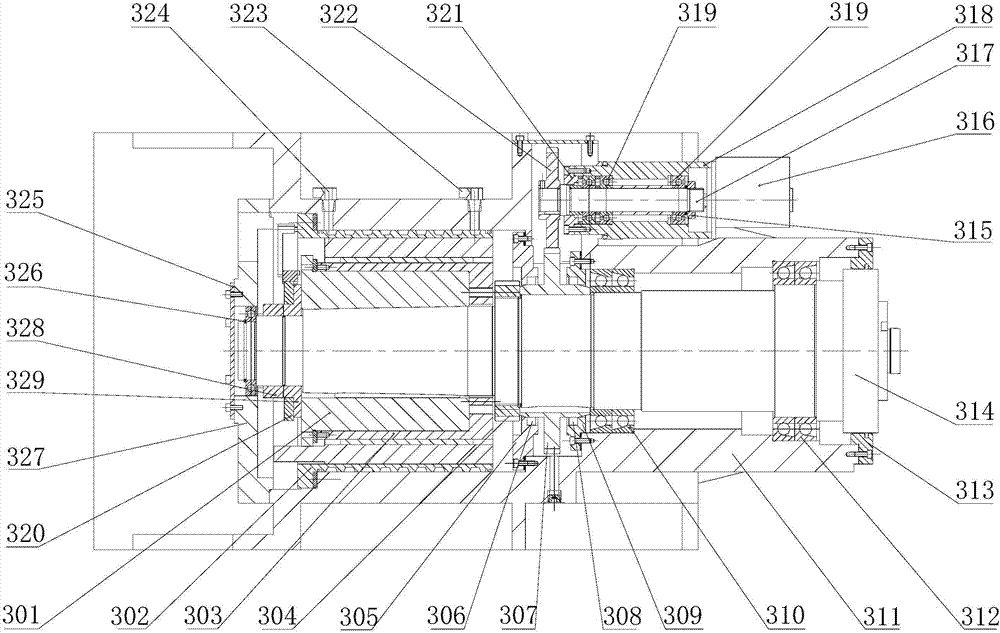

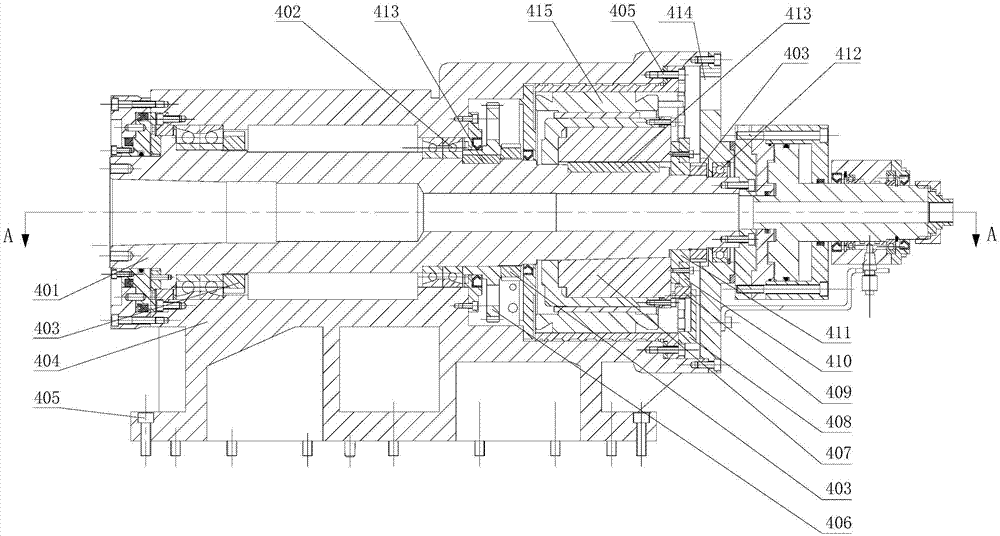

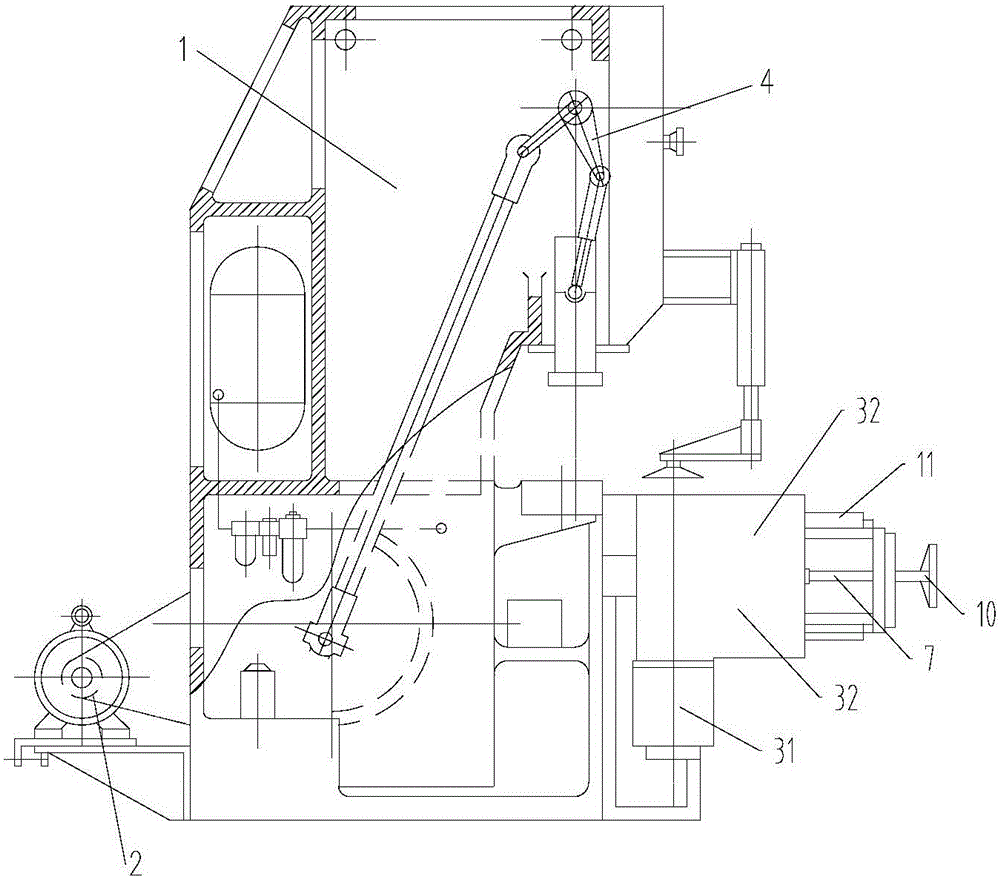

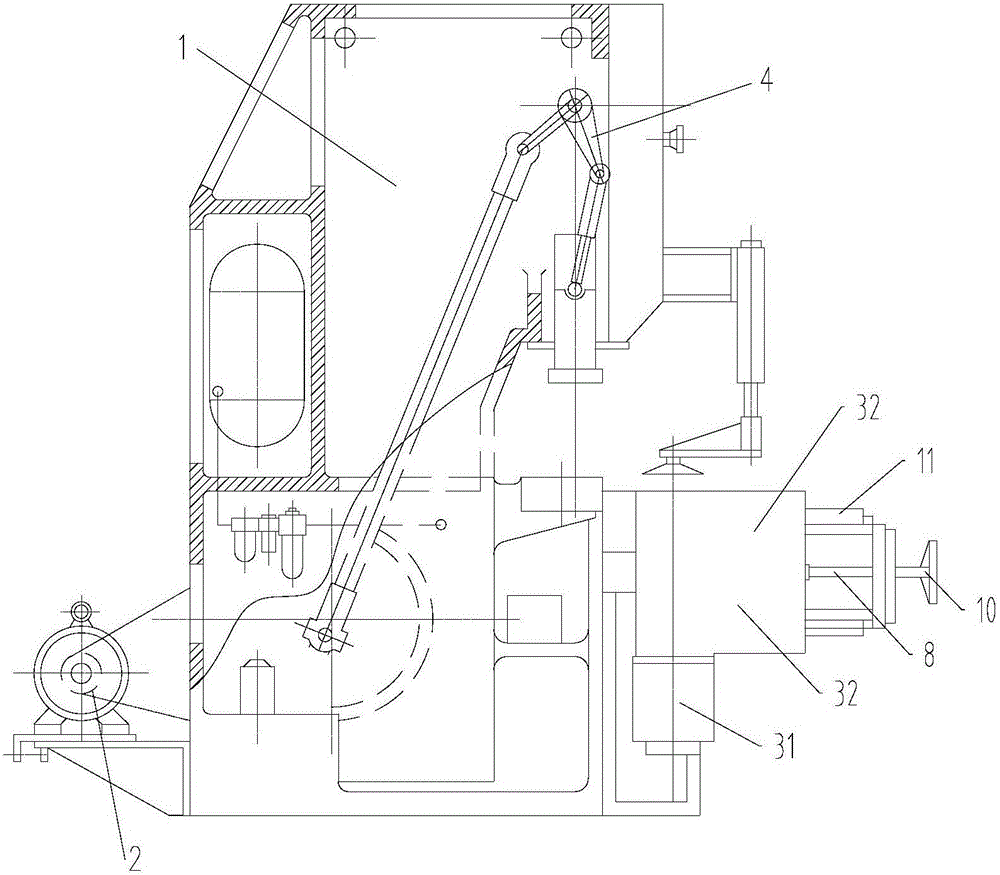

Artificial tooth machining machine

ActiveCN102871751AImprove processing efficiencyImprove machining accuracyArtificial teethMovement controlProcessing accuracy

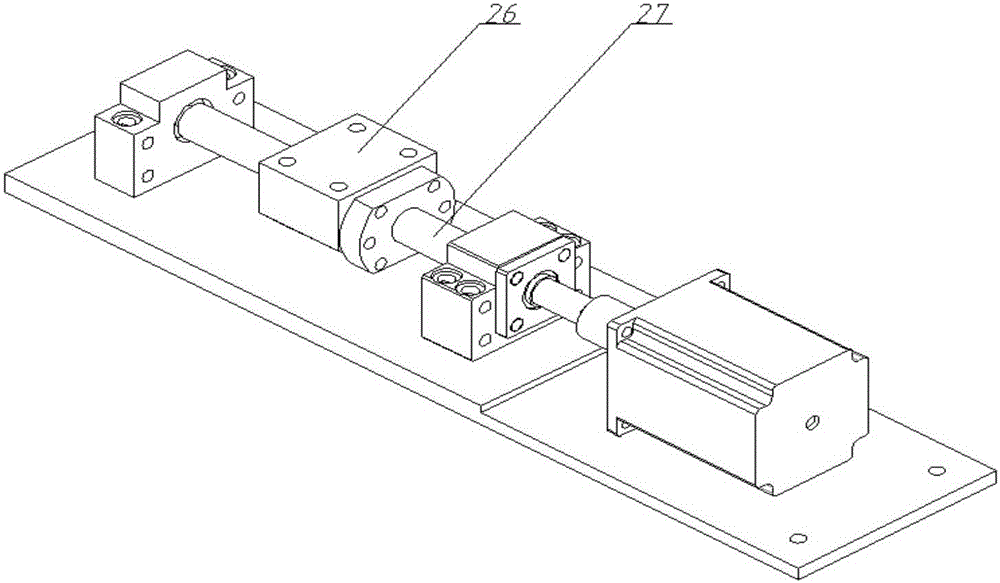

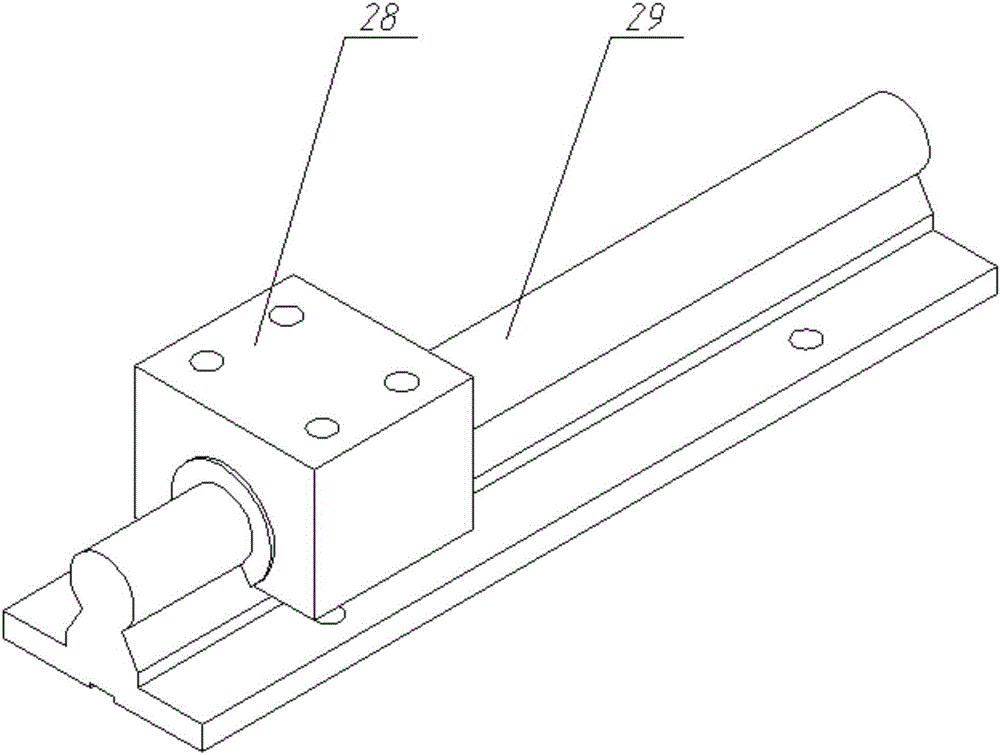

The invention discloses an artificial tooth machining machine which comprises a base, a cutting cooling system, a too component, a double-main-shaft machining system, an A-axis workpiece rotating device, a Z-axis feed device, an X-axis feed device, a Y-axis feed device and a movement control system. The tool component is used for fixed artificial tooth blank. The double-main-shaft machining system is provided with an artificial tooth cutter. The A-axis workpiece rotating device is used for driving the tool component to rotate. The Z-axis feed device is used for driving the double-main-shaft machining system to move Z-axially. The X-axis feed device used for driving the Z-axis feed device to move X-axially. The Y-axis feed device used for driving the A-axis workpiece rotating device to move Y-axially. The movement control system is used for controlling the Z-axis feed device, the X-axis feed device, the Y-axis feed device and the A-axis workpiece rotating device to move. The double-main-shaft machining system is mounted on the Z-axis feed device. The Z-axis feed device is mounted on the X-axis feed device. The A-axis workpiece rotating device mounted on the Y-axis feed device. Four-axis linkage is achieved, machining efficiency is high, and machining precision is improved.

Owner:常州特舒隆机电设备有限公司

Speed-adjustable permanent magnet inductive worm and wormwheel transmission device

ActiveCN103036392AImprove exercise efficiencyReduce feverDynamo-electric gearsDrive motorMagnetic flux

The invention relates to the technical field of mechanical transmission, in particular to a speed-adjustable permanent magnet inductive worm and wormwheel transmission device which comprises a drive assembly, a driven assembly and a speed adjusting device assembly. The drive assembly is fixed arranged on the speed adjusting device assembly, a worm of the drive assembly and a wormwheel of the driven assembly form an included angle of 90 degrees, and uniform air gaps are formed between the worm and the wormwheel. When the worm is driven by a drive motor to rotate, the whole drive assembly can be driven by the speed adjusting device assembly to conduct side-to-side motion, so that the worm can be driven to move away from the wormwheel or move close to the wormwheel, and at the same time, sizes of the air gaps of conductive bodies or conductive body layers on the worm and of the permanent magnet on the wormwheel are changed and magnetic flux of an air-gap magnetic field can be quickly adjusted. Output rotating speed and torque can be better and more quickly controlled and the aim of achieving infinitely variable speed and transmitting motion and power between two mutually perpendicular shafts is achieved.

Owner:JIANGSU UNIV

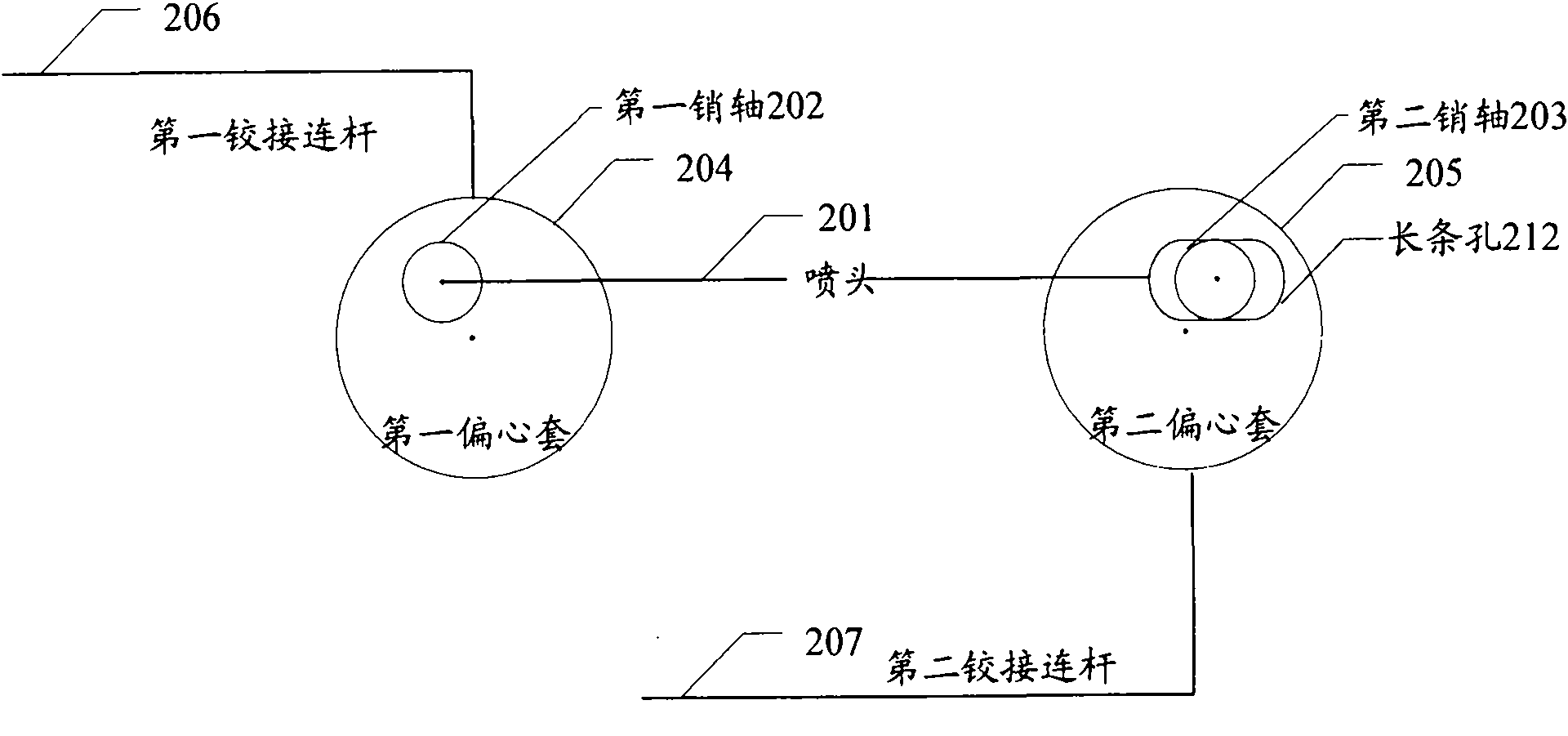

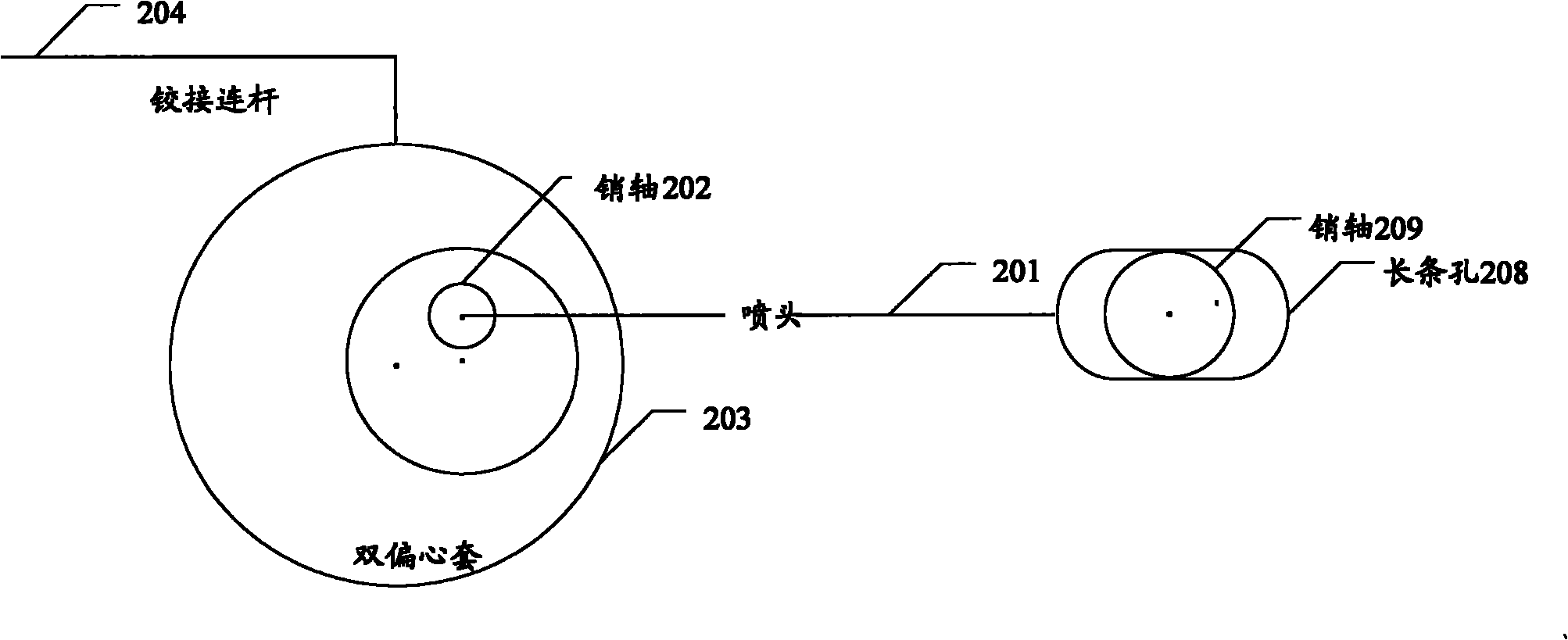

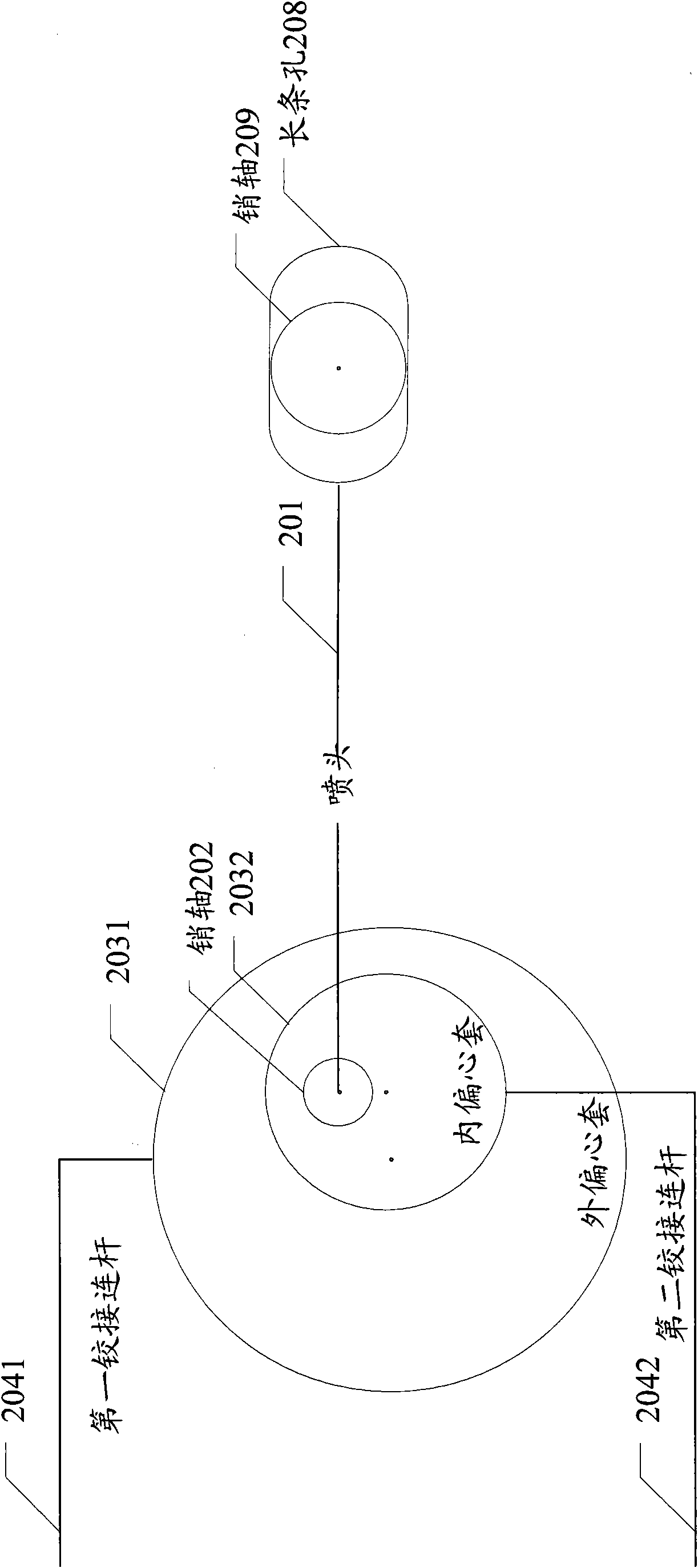

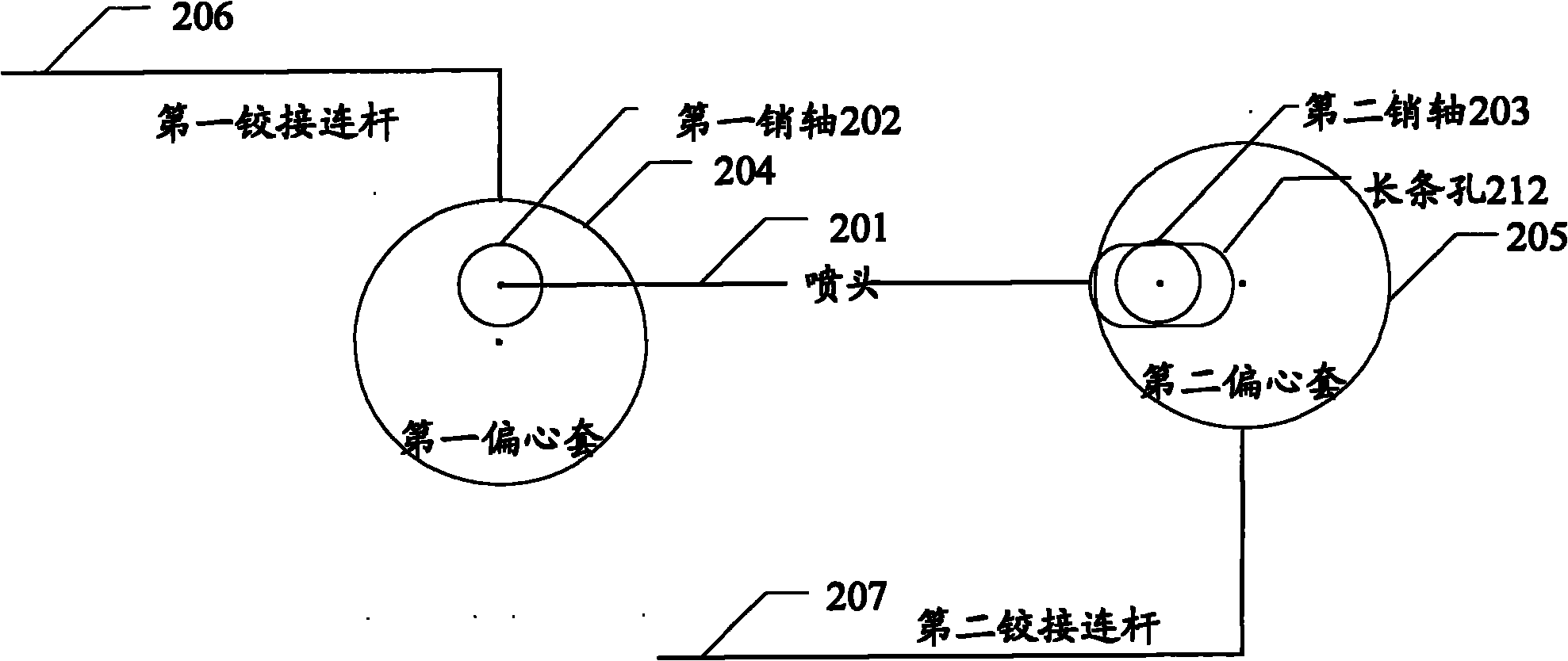

Adjusting device

Owner:NEW FOUNDER HLDG DEV LLC +2

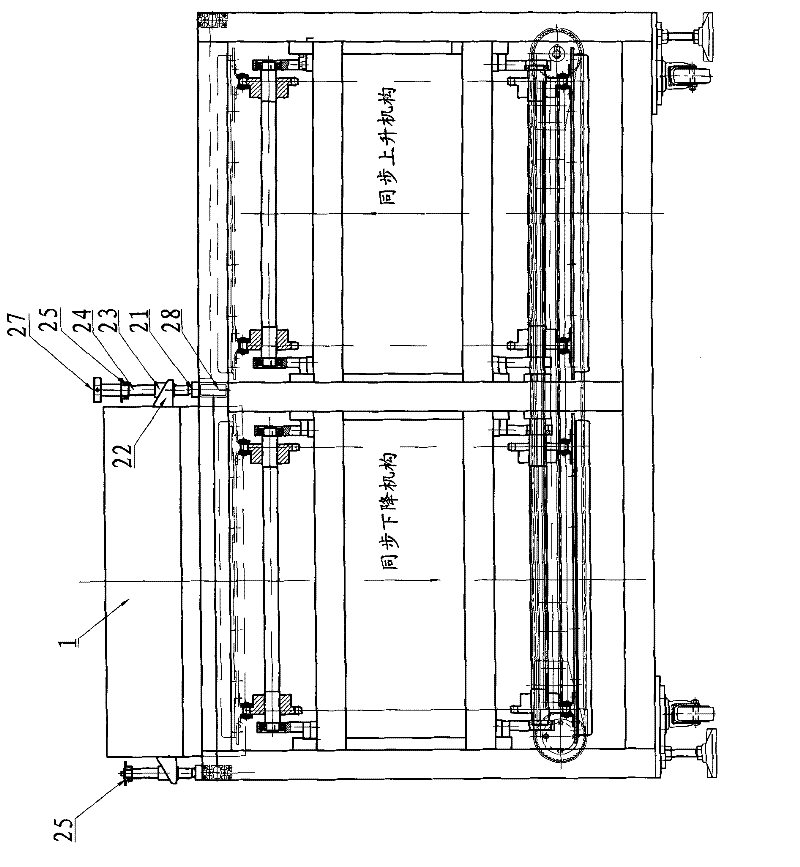

Printing machine flash oven height synchronous adjustment mechanism

A height synchronous adjustment mechanism for a flash oven of a printing machine, including a frame, ear seats, threaded sleeves, screws, synchronous sprockets, chains, handwheels, and a flash oven. The four ear seats are symmetrically arranged on the left and right sides of the flash oven, and the flash oven The center of gravity is supported by four threaded sleeves, and a synchronous sprocket is fixedly installed on the upper end of each screw, and is in the same plane. The chain is set on the four synchronous sprockets, and the lower end of the screw is rotatable through the limit seat Fixed on the frame, with a hand wheel on a screw rod. As long as any one of the synchronous sprockets is rotated, the other three synchronous sprockets will rotate at the same time. Since the synchronous sprockets are fixedly installed on the screw, the rotation of the synchronous sprocket will drive the screw to rotate, thereby driving the threaded sleeve to rise and fall to realize the lifting of the flash oven. Adjustment, in the process of lifting, the movement is smooth, and there will be no crawling phenomenon. Since the hand wheel is set above the flash oven, the operation is very convenient.

Owner:常州市奥伦自动化设备有限公司

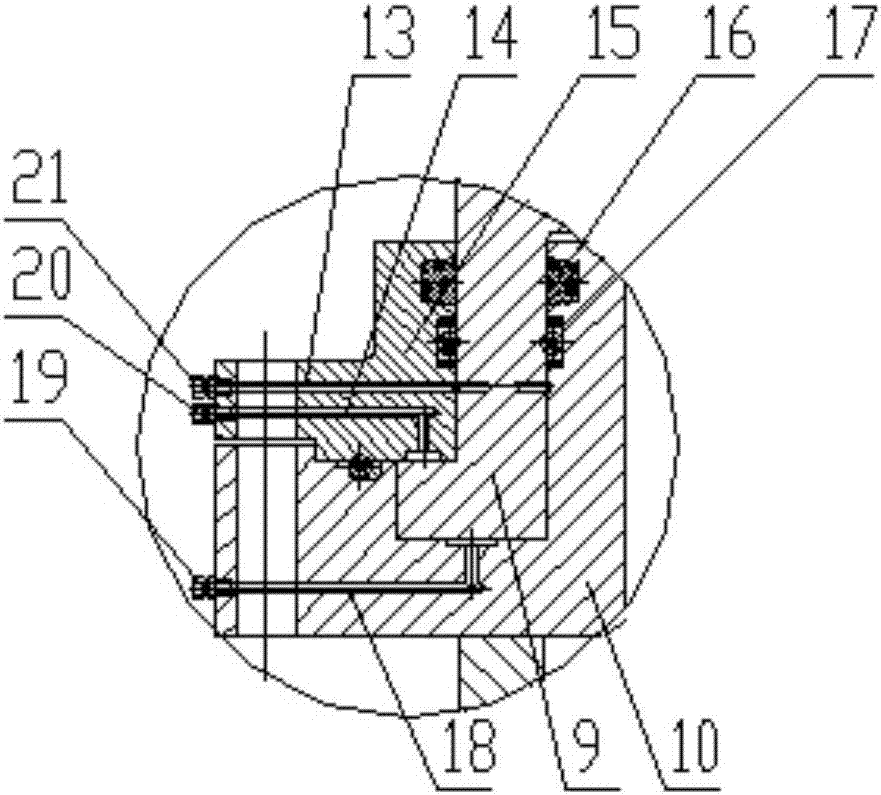

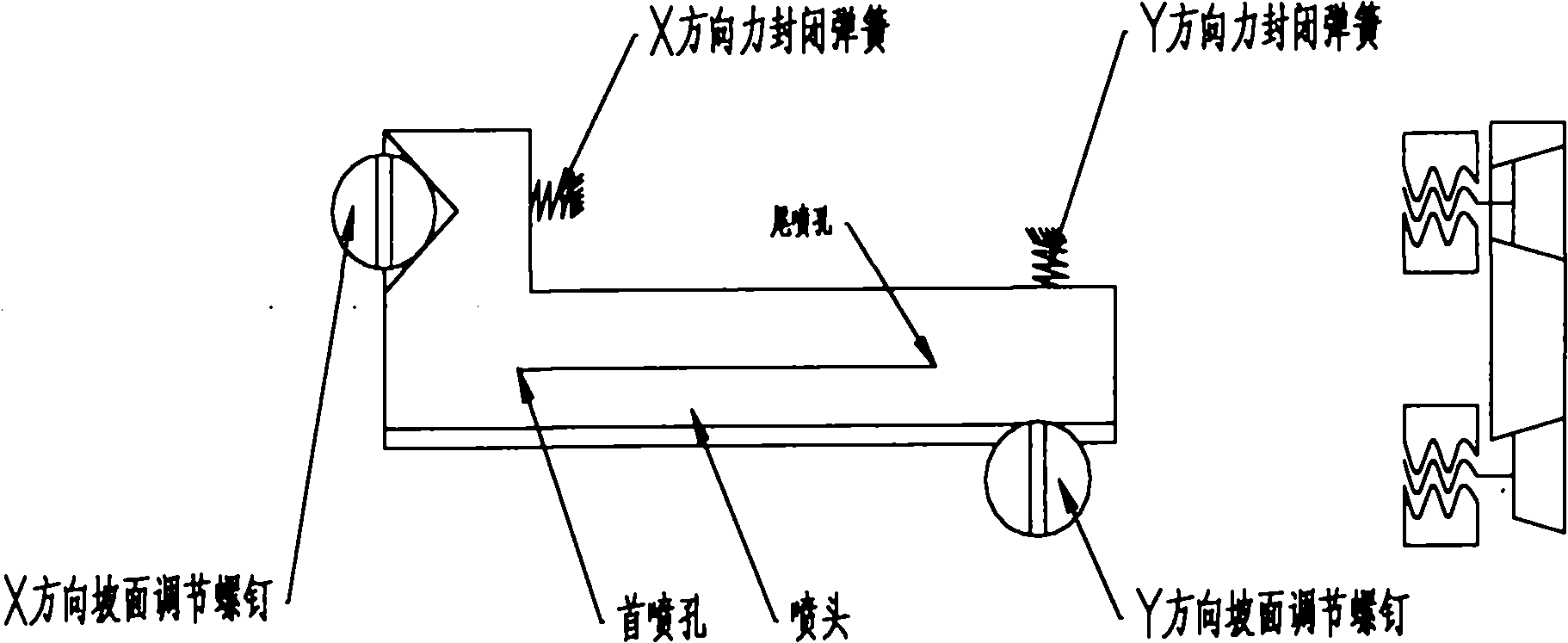

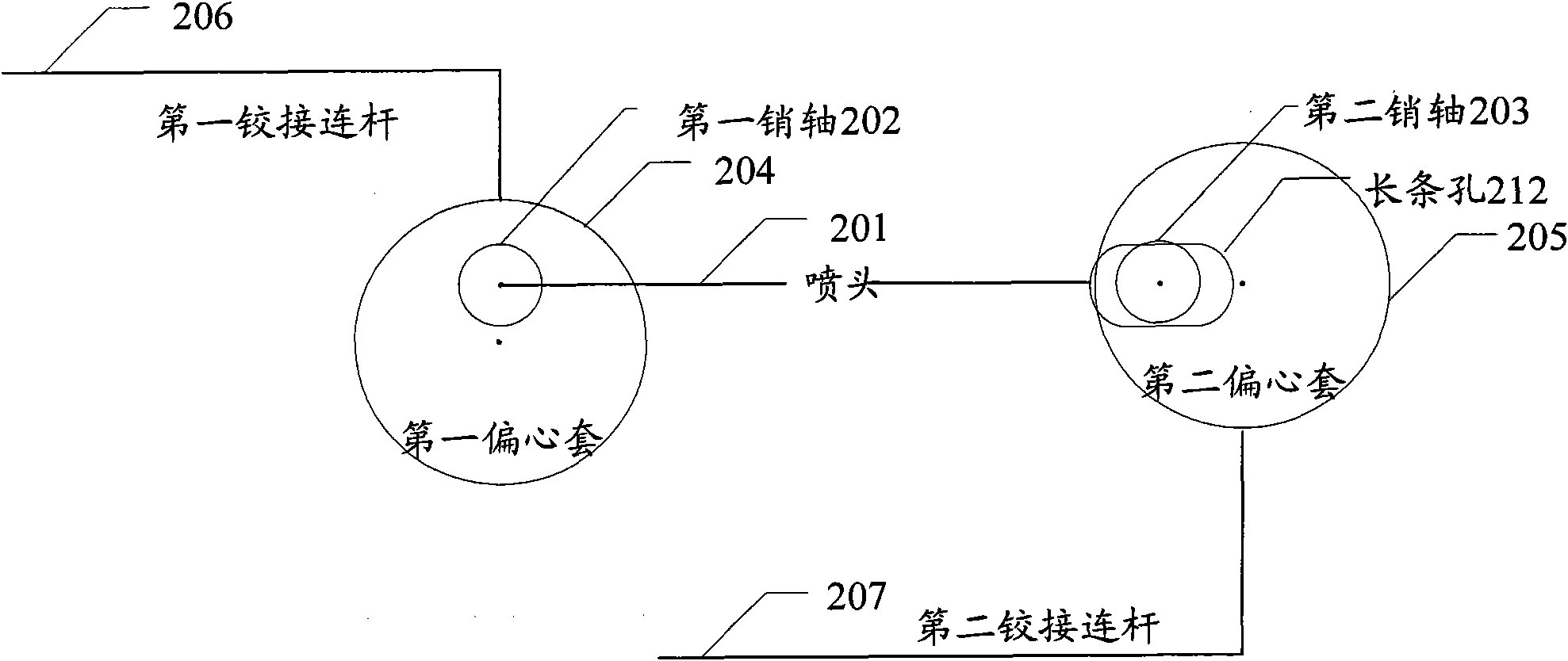

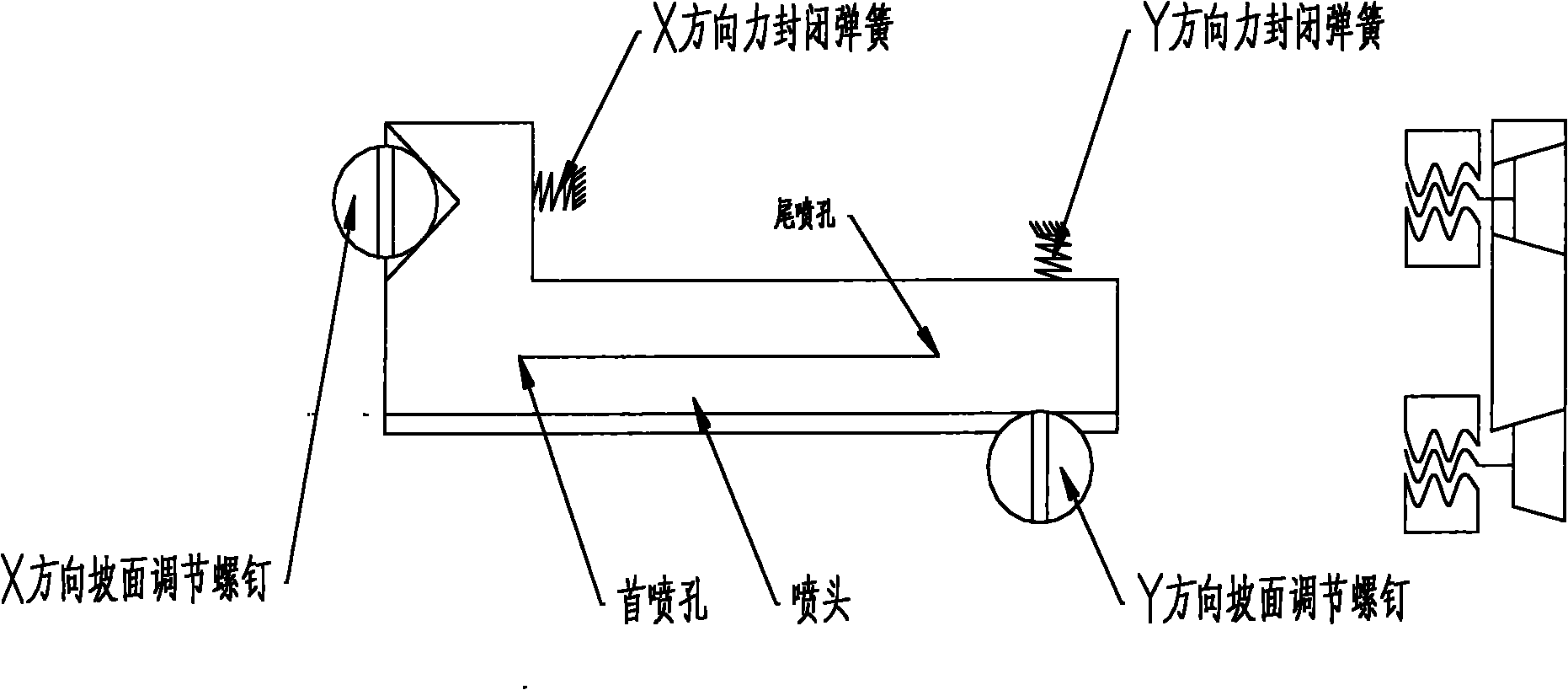

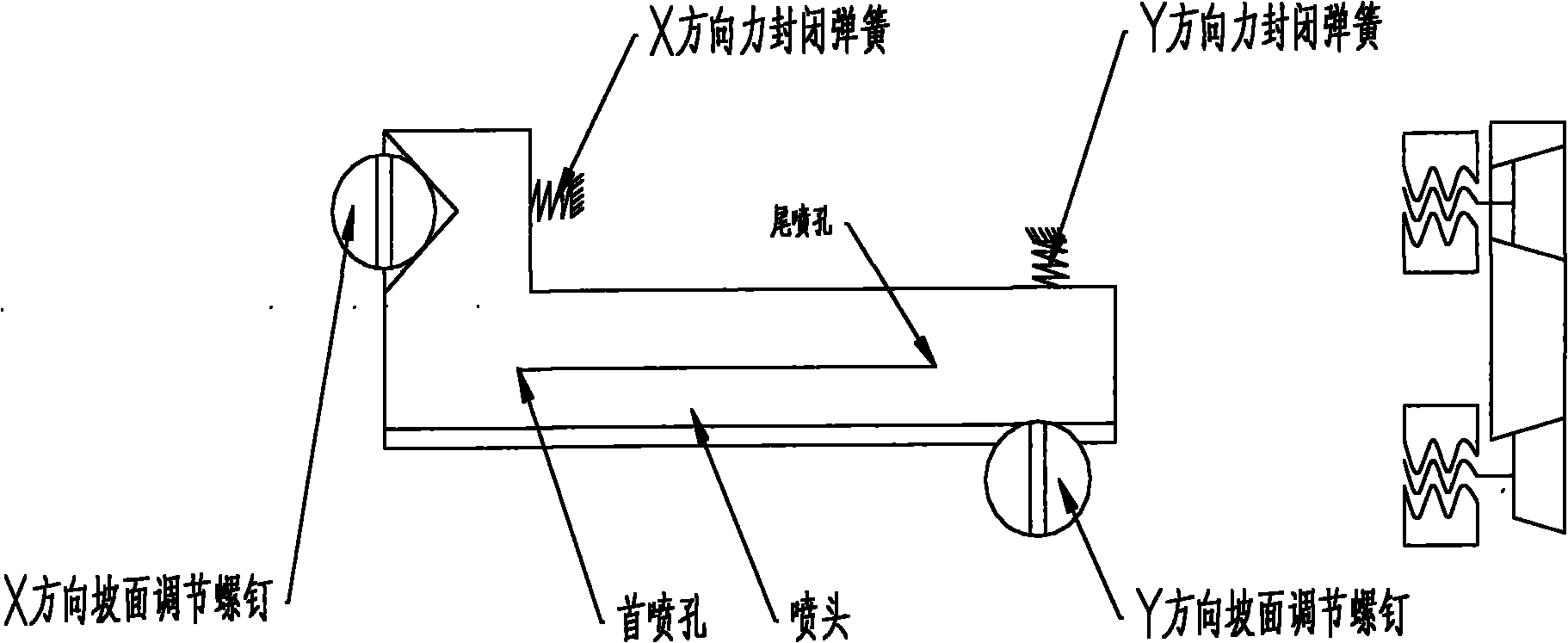

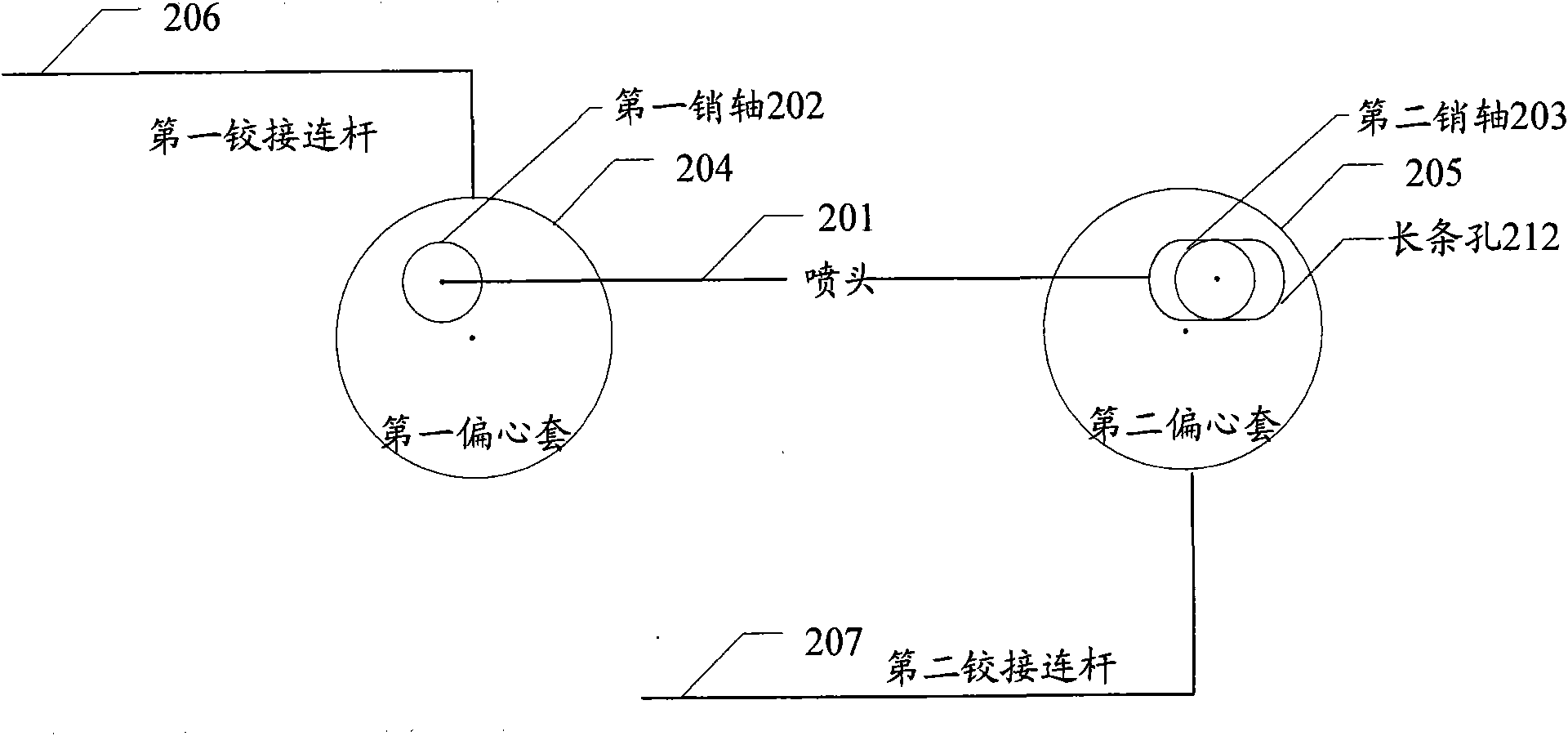

Micro-force measuring type three-dimensional comprehensive thread measuring machine measuring head and measuring method thereof

The invention provides a micro-force measuring type three-dimensional comprehensive thread measuring machine measuring head and a measuring method thereof, which can simply and accurately measure thedisplacement of a probe so as to measure the spatial position of a measured thread. The micro displacements of the probe in the horizontal direction and the vertical direction are respectively measured through the transverse micro displacement measuring system and the longitudinal micro displacement measuring system. After the probe is in pre-contact with a measured thread and is driven by the three-dimensional comprehensive thread measuring machine, the probe respectively displaces in the horizontal direction and the vertical direction, the two groups of parallel reeds are used as guide mechanisms and are respectively stretched, the reading head of the linear grating system and the long grating relatively displace, and the displacement is measured. The measuring head is used for thread detection of the micro-force force measurement type three-dimensional comprehensive thread measuring machine.

Owner:CHOTEST TECH INC

Adjusting device

Owner:新方正控股发展有限责任公司 +2

Twisted string drive-based finger of robot

InactiveCN102862163AUnlimited rotationRealize coupling rotationGripping headsEngineeringMechanical engineering

The invention relates to a twisted string drive-based finger of a robot. The twisted string drive-based finger of the robot comprises a proximal finger section, a middle finger section, a tail finger section, a middle finger shaft, a tail finger shaft, a coupling connecting rod, a twisted string rotary shaft, a twisted string, a restoring spring and a motor. The motor is fixedly connected on the proximal finger section, the middle finger section is connected on the proximal finger section through the middle finger shaft, the tail finger section is connected on the middle finger section through the tail finger shaft, and the tail finger section and the proximal finger section are connected through the coupling connecting rod. One end of the twisted string is connected on the rotary shaft of the motor while the other end is connected on the middle finger section through the twisted string rotary shaft. Both ends of the restoring spring are respectively connected on the proximal finger section and the middle finger section. The restoring spring surrounds the periphery of the twisted string. The twisted string drive-based finger of the robot provided by the invention is compact in structure, small in size, large in driving force and accurate and convenient to control, and is suitable for being installed on the finger of the rotor.

Owner:NANCHANG UNIV

Tablet automatic storage and dispensing device

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Guide boot

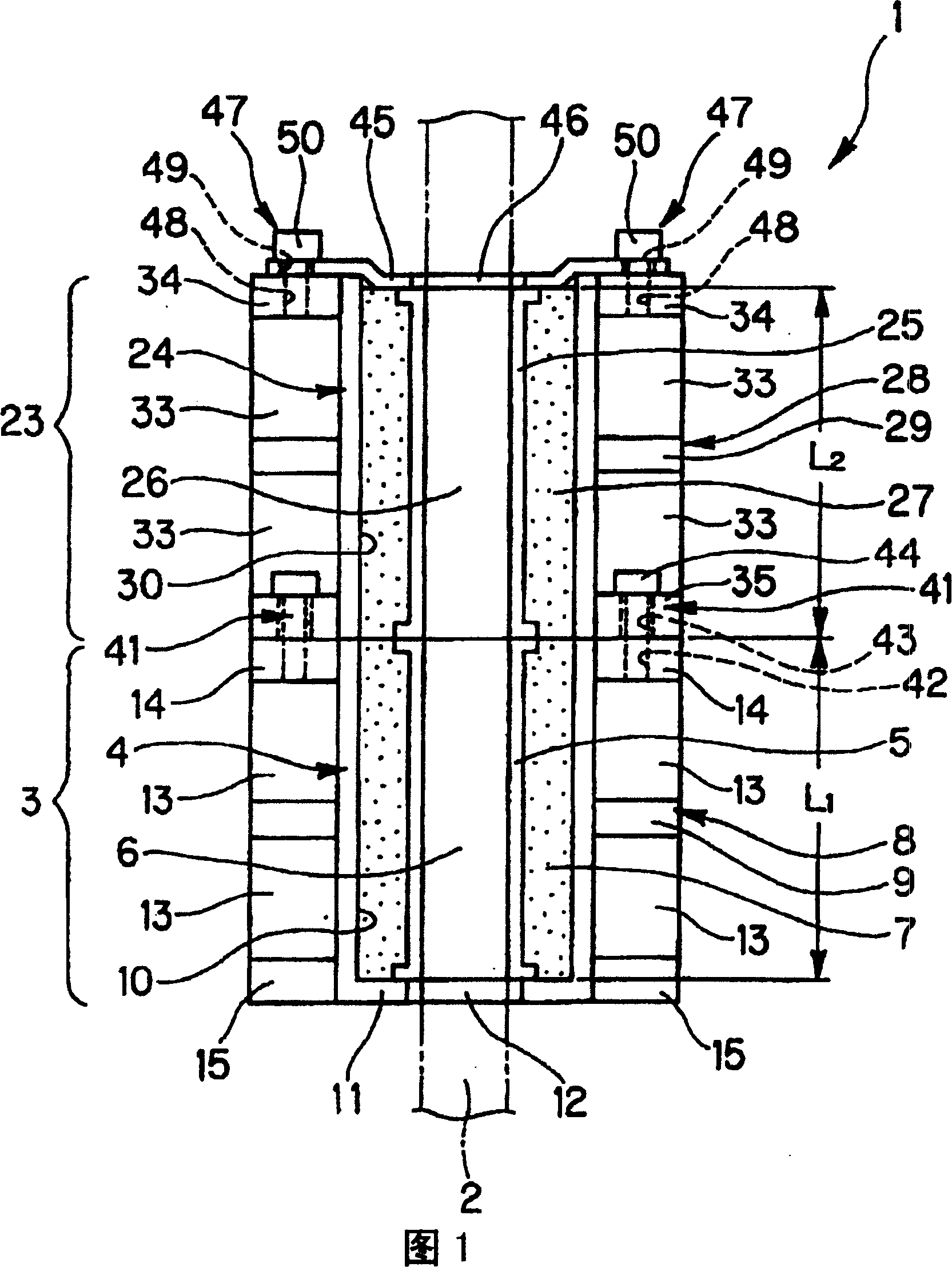

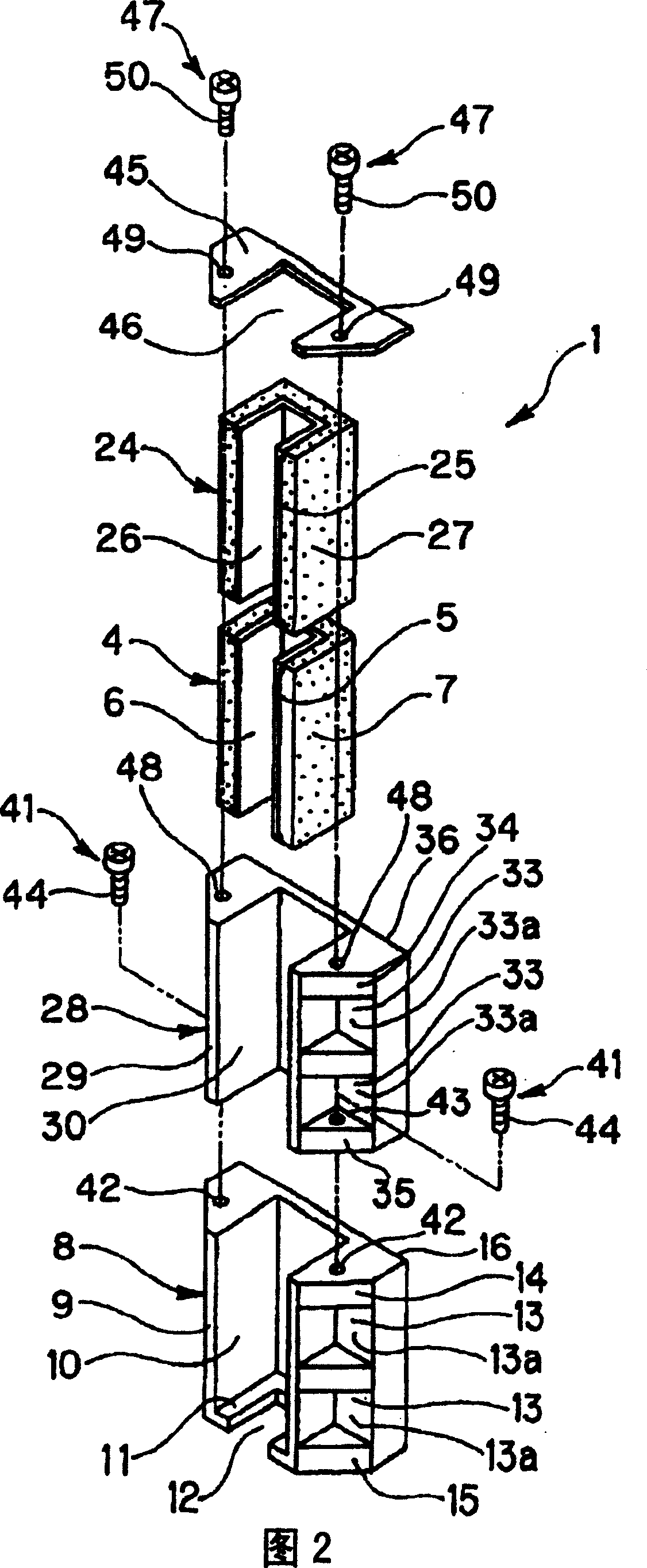

InactiveCN1321050CImprove development efficiencyIncrease productivityElevatorsGlass fiberEngineering

The guide shoe comprises a guide shoe assembly having a shoe assembly with a shoe to be slid along the guide rail comprising a compound of ultrahigh molecular weight polyethylene and glass fiber reinforced nylon and a housing for holding the shoe assembly to be fixed to a mobile body, and a connection guide shoe assembly having a connection shoe assembly to be slid along the guide rail and a connection housing holding the connection shoe assembly. The connection guide shoe assembly can be connected to the guide shoe assembly, and the length in sliding directions of the shoes is adjustable. To provide a guide shoe capable of improving development / production efficiency and consequently reducing development / production costs, wherein a problem of a stick slip phenomenon is solved.

Owner:HITACHI LTD +1

Artificial tooth machining machine

ActiveCN102871751BImprove processing efficiencyRealize front and back processingArtificial teethControl systemEngineering

The invention discloses an artificial tooth machining machine which comprises a base, a cutting cooling system, a too component, a double-main-shaft machining system, an A-axis workpiece rotating device, a Z-axis feed device, an X-axis feed device, a Y-axis feed device and a movement control system. The tool component is used for fixed artificial tooth blank. The double-main-shaft machining system is provided with an artificial tooth cutter. The A-axis workpiece rotating device is used for driving the tool component to rotate. The Z-axis feed device is used for driving the double-main-shaft machining system to move Z-axially. The X-axis feed device used for driving the Z-axis feed device to move X-axially. The Y-axis feed device used for driving the A-axis workpiece rotating device to move Y-axially. The movement control system is used for controlling the Z-axis feed device, the X-axis feed device, the Y-axis feed device and the A-axis workpiece rotating device to move. The double-main-shaft machining system is mounted on the Z-axis feed device. The Z-axis feed device is mounted on the X-axis feed device. The A-axis workpiece rotating device mounted on the Y-axis feed device. Four-axis linkage is achieved, machining efficiency is high, and machining precision is improved.

Owner:常州特舒隆机电设备有限公司

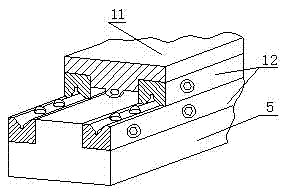

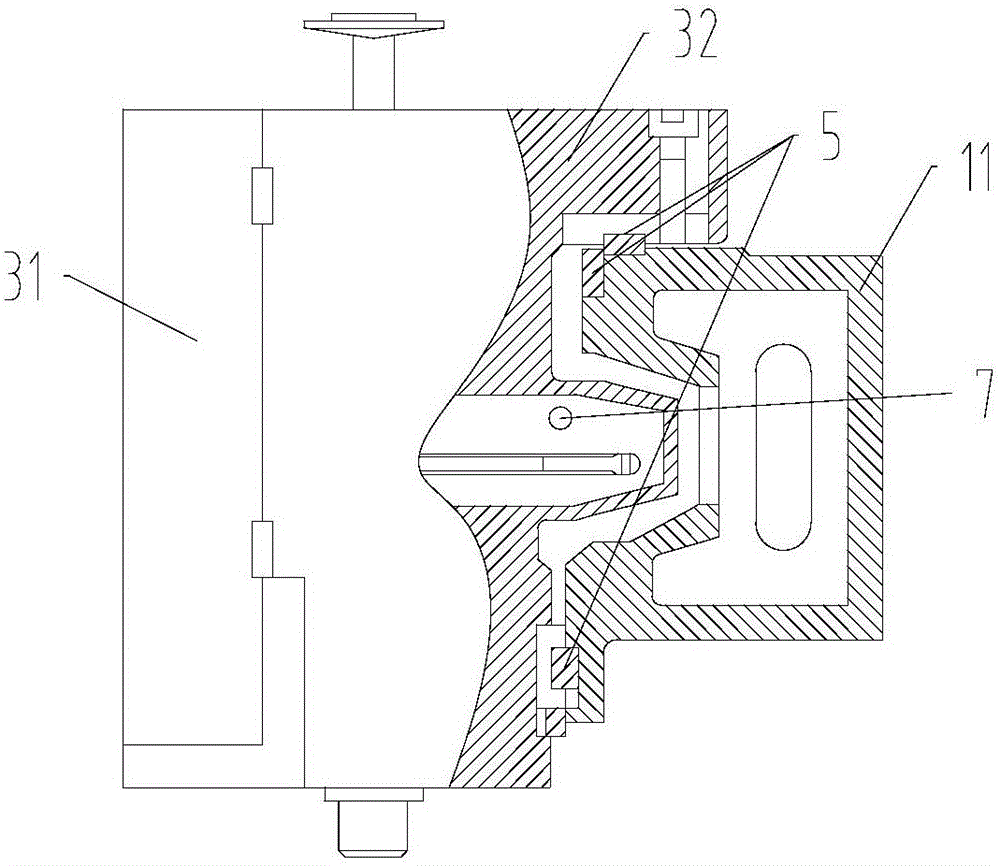

High-precision pneumatic chuck structure

The invention relates to a high-precision pneumatic chuck structure. The high-precision pneumatic chuck structure is arranged on a flange plate of a machine tool and comprises a rotating shaft fixedlyconnected with the flange plate, a pneumatic assembly arranged at the front portion of the rotating shaft, a chuck assembly arranged on the pneumatic assembly and a ventilation bearing arranged at the rear portion of the rotating shaft, wherein the ventilation bearing is an aerostatic bearing; a ventilation groove is arranged in the rotating shaft; the ventilation groove communicates with the pneumatic assembly and the aerostatic bearing; one part of the air introduced by the aerostatic bearing forms an air film in the aerostatic bearing; and the other part of the air enters the pneumatic assembly through the ventilation groove to drive the chuck assembly. Due to the homogenization effect of the air film, the rotation precision can be further improved, and the influence of the shape errorof the mechanical bearing on the rotation precision and the rotation stability of a chuck is greatly reduced; and meanwhile, in the aerostatic bearing, a rotary part of the chuck is separated from astatic part by the air film, and direct contact of mechanical parts is avoided, so that friction force in operation is effectively reduced.

Owner:JIANGSU JITRI JINGKAI HIGH VALUE MFG CO LTD

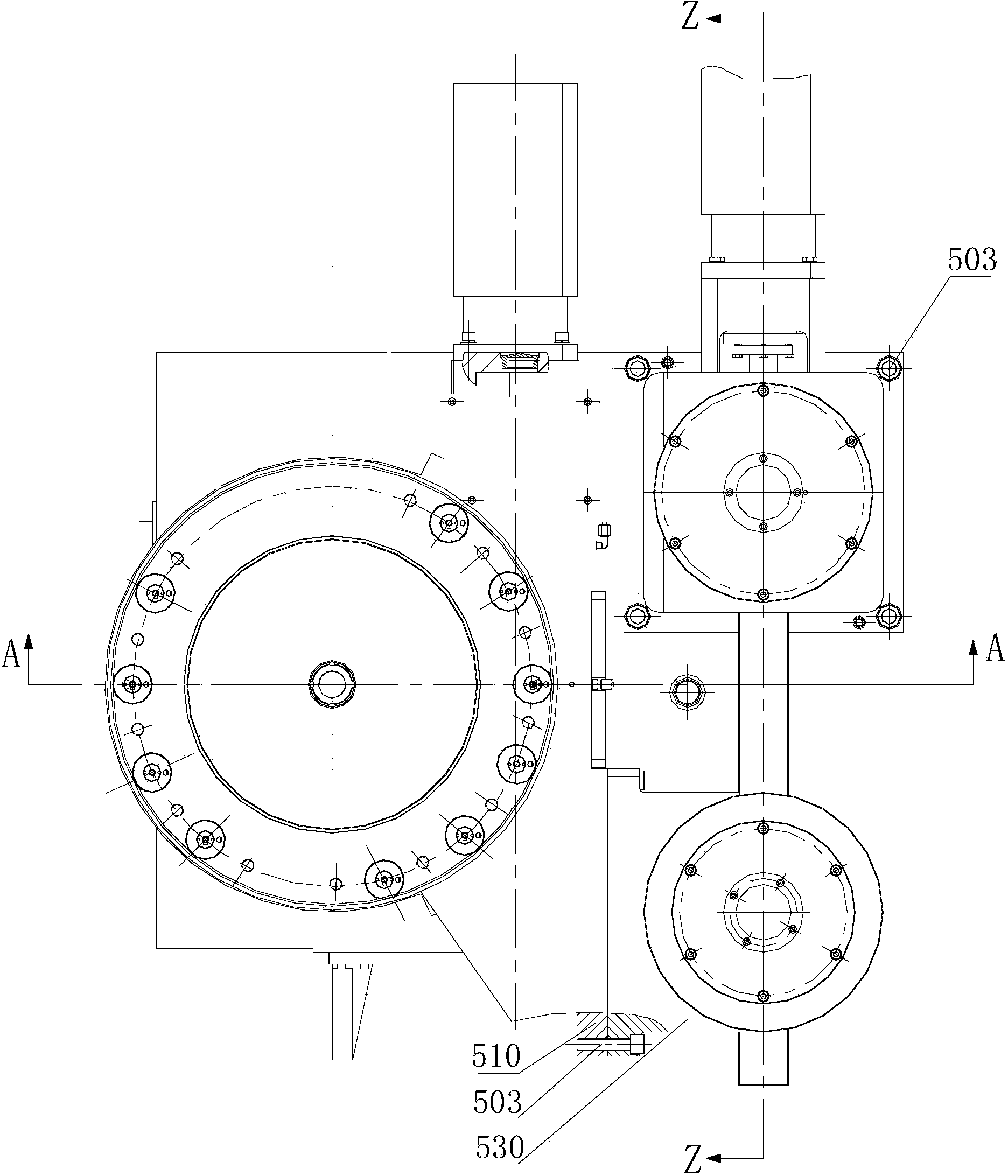

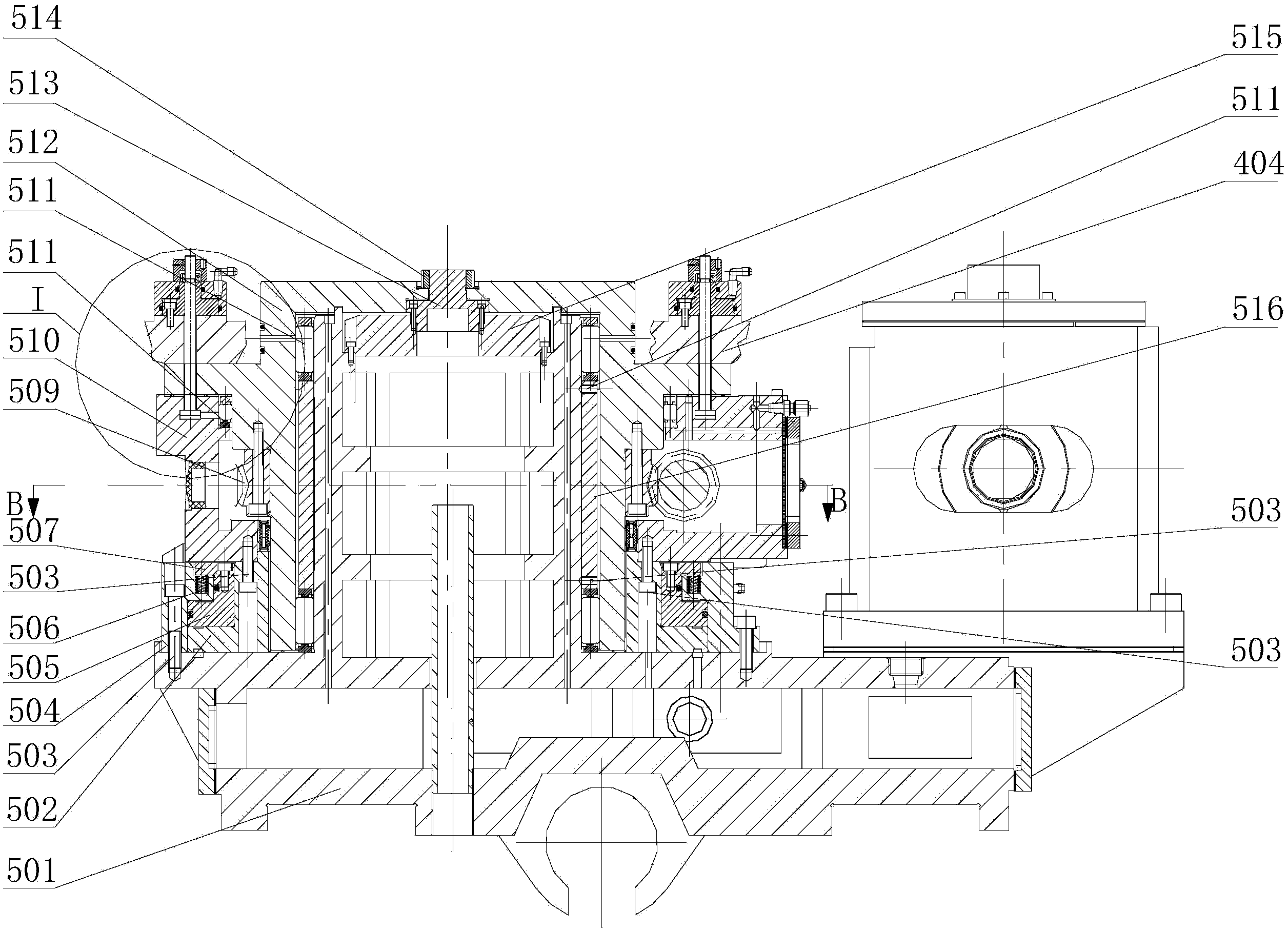

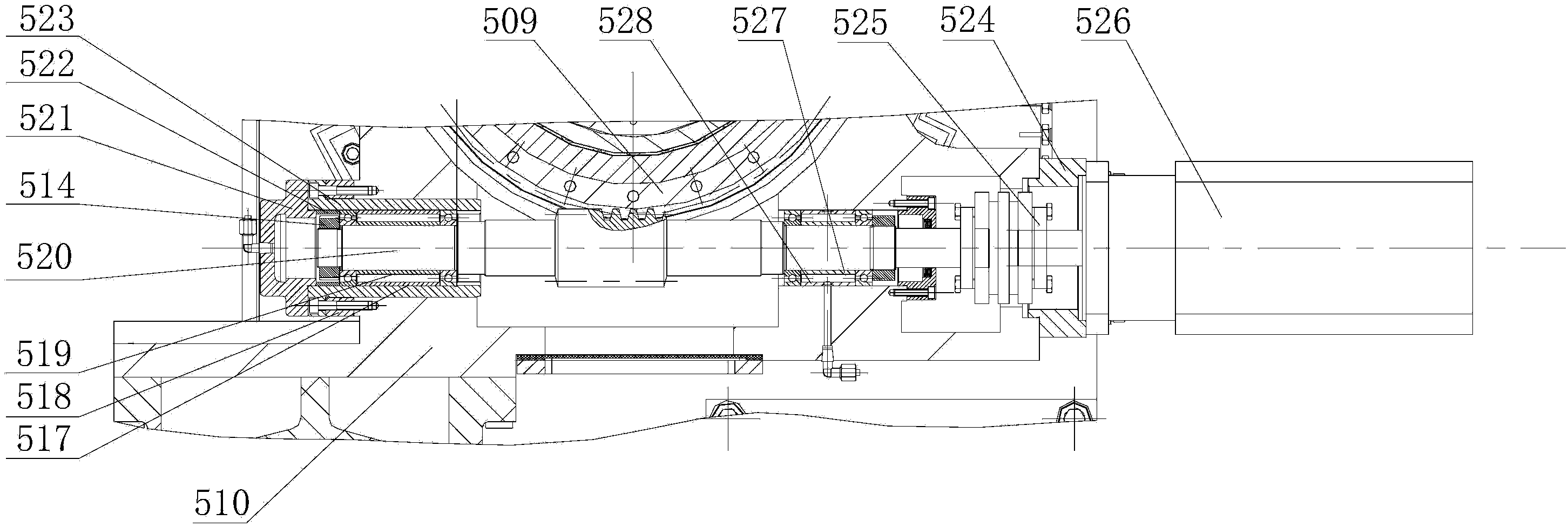

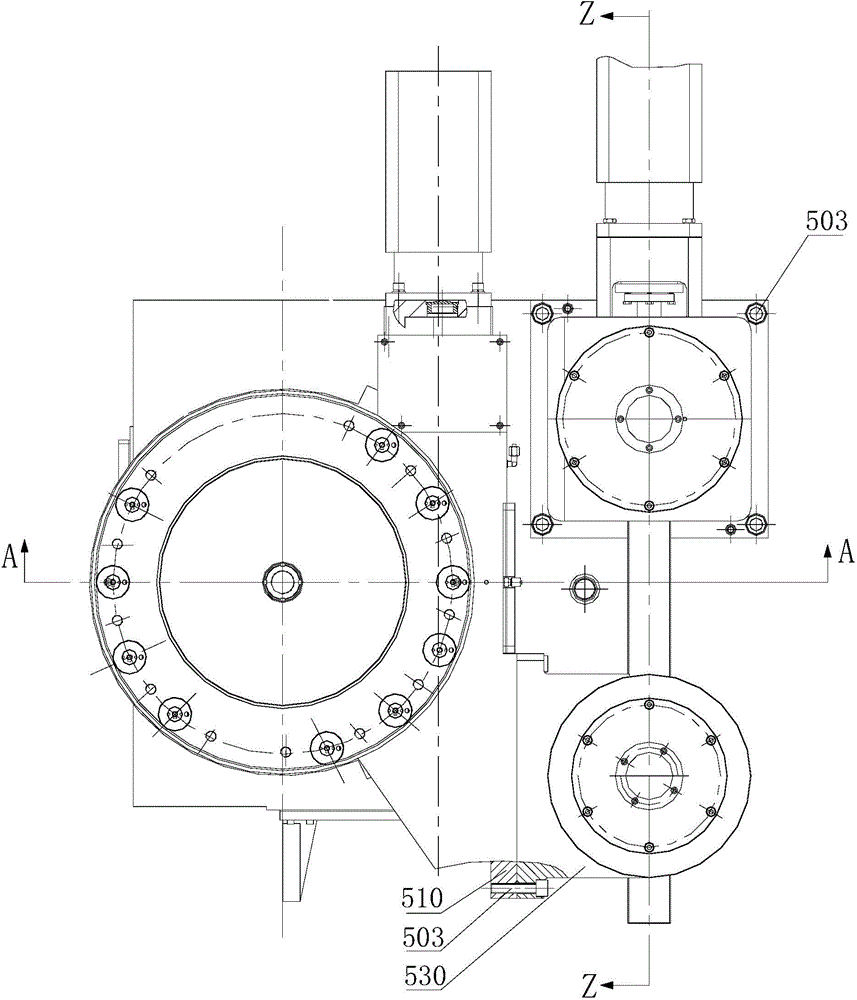

Rotary table transmission device of numerical control spiral bevel gear milling machine

ActiveCN103586725AReduce wearReduced finishing accuracyFeeding apparatusGear-cutting machinesLow speedSlide plate

The invention relates to a rotary table transmission device of a numerical control spiral bevel gear milling machine. The rotary table transmission device comprises a feeding sliding plate and a rotary table base and is characterized by further comprising a worm gear bottom sleeve, a worm and gear pair, a rotary table oscillating bar mechanism, a second clamping oil cylinder, a first clamping oil cylinder and a supporting base, wherein the worm gear bottom sleeve and the worm and gear pair are used for driving a rotary table to rotate. The worm gear bottom sleeve is supported on the rotary table base, a worm gear is fixedly installed on the worm gear bottom sleeve, and the lower end of the rotary table base is supported on the top surface of the feeding sliding plate through a first flange plate. The rotary table oscillating bar mechanism is fixedly installed on the top surface of the feeding sliding plate. The supporting base is fixedly installed on the rotary table base. A worm of the worm and gear pair is fixedly installed on the rotary table base in a supporting mode. The rotary table transmission device has the advantages that workpiece boxes needed by rough machining or finish machining of workpieces can be separated in a rotating mode, unnecessary abrasion is reduced, precision of finishing machining is improved, besides, requirements for machining two kinds of tooth gears of a user can be met, the structural design is reliable, rigidity is good, the precision is high, and low-speed crawling does not exist.

Owner:天津第一机床有限公司

Novel machine tool bed casting assembly

InactiveCN102886685AImprove shock absorptionStrong impact resistanceFeeding apparatusLarge fixed membersEngineeringHeavy load

The invention relates to a novel machine tool bed casting assembly which comprises an integrally cast chassis base and an integrally cast working platform, wherein a plurality of T-shaped slots are arranged at the top of the working platform; a guide rail is arranged at the top of the chassis base, a support is arranged in the center of the chassis base, and an X-axis driving device connected with the working platform is arranged on the support; and a guide rail oil chamber is arranged at the bottom of the working platform, and the guide rail oil chamber is spaced on the guide rail. The novel machine tool bed casting assembly has the characteristics of reliable structure, good working stability, strong guide rail impact resistance, difficulty in wearing and the like. Because pressure oil is introduced between the guide rail and the working platform contact surface, a moving part is slightly floated, the friction factor is extremely small, the transmission efficiency is very high, and the crawling phenomenon can not occur during low-speed movement. Worms and gears are adopted for the X-axis transmission of the working platform, so that the working platform has the characteristics of large transmission ratio, smooth transmission and small noise. The novel machine tool bed casting assembly well solves the problems that the traditional working platform guide rail has poor impact resistance, is not applicable to heavy-load processing, is easy to wear and the like.

Owner:HUBEI JIANGHAN HEAVY IND

Two-degree-of-freedom high-precision large-stroke air-bearing workpiece platform

InactiveCN103592824BNo additional mechanical contact forceAchieve high speed movementPhotomechanical exposure apparatusMicrolithography exposure apparatusAir bearingEngineering

The invention discloses a two-degree-of-freedom high-precision large-stroke air-bearing workpiece platform, comprising a marble base, an X-direction motion bench and a Y-direction motion bench, wherein the marble base is located at the bottoms of the X-direction motion bench and the Y-direction motion bench and used for supporting the whole X-direction motion bench and the whole Y-direction motion bench, the Y-direction motion bench is erected on the X-direction motion bench, and the Y-direction motion bench and the X-direction motion bench are coupled through the X crossbeam of the X-direction motion bench so as to realize transfer of X-direction motion to the Y-direction motion bench, which enables the workpiece platform to have an X-Y two-degree-of-freedom motion function. According to the invention, the Y-direction motion bench is erected on the X-direction motion bench, thereby forming the H-shaped two-degree-of-freedom high-precision large-stroke air-bearing workpiece platform; linear motor driving and friction-free air-bearing guide rail guiding are employed by the workpiece platform, so the platform can realize high-speed and large-stroke motion and high-precision positioning.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

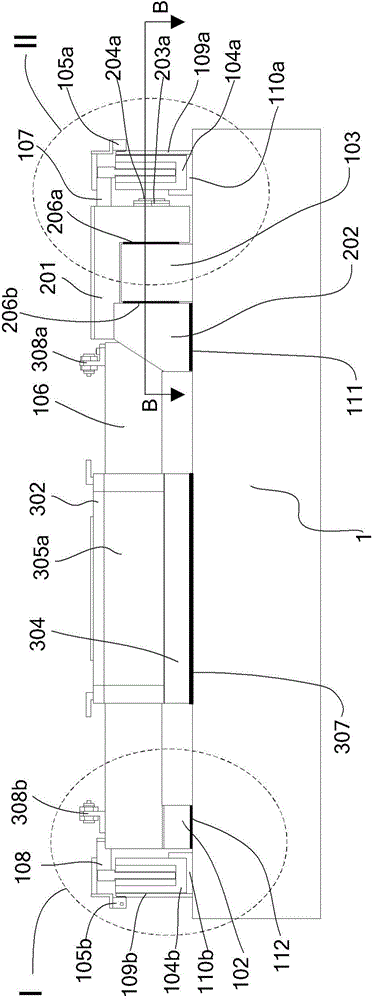

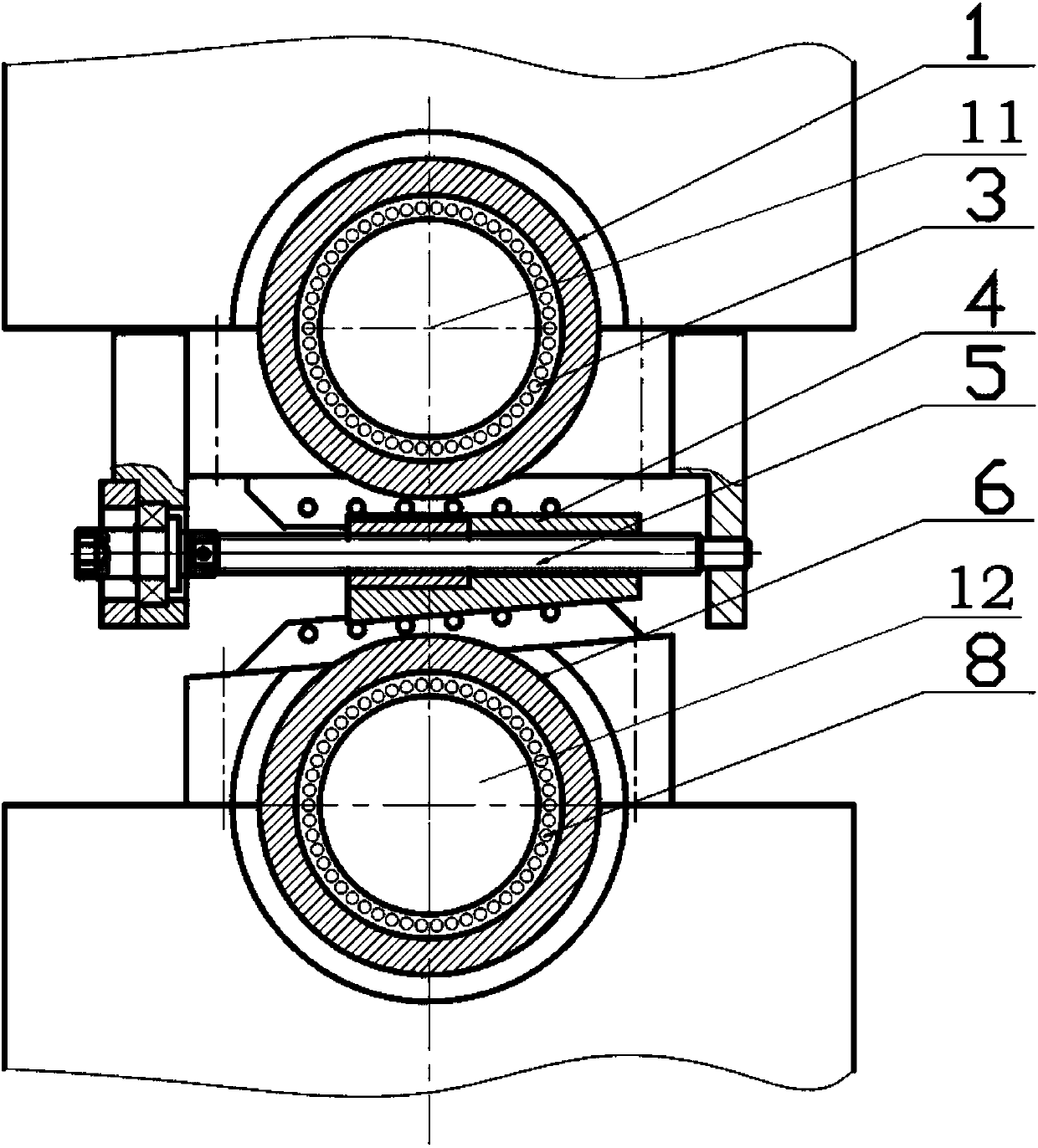

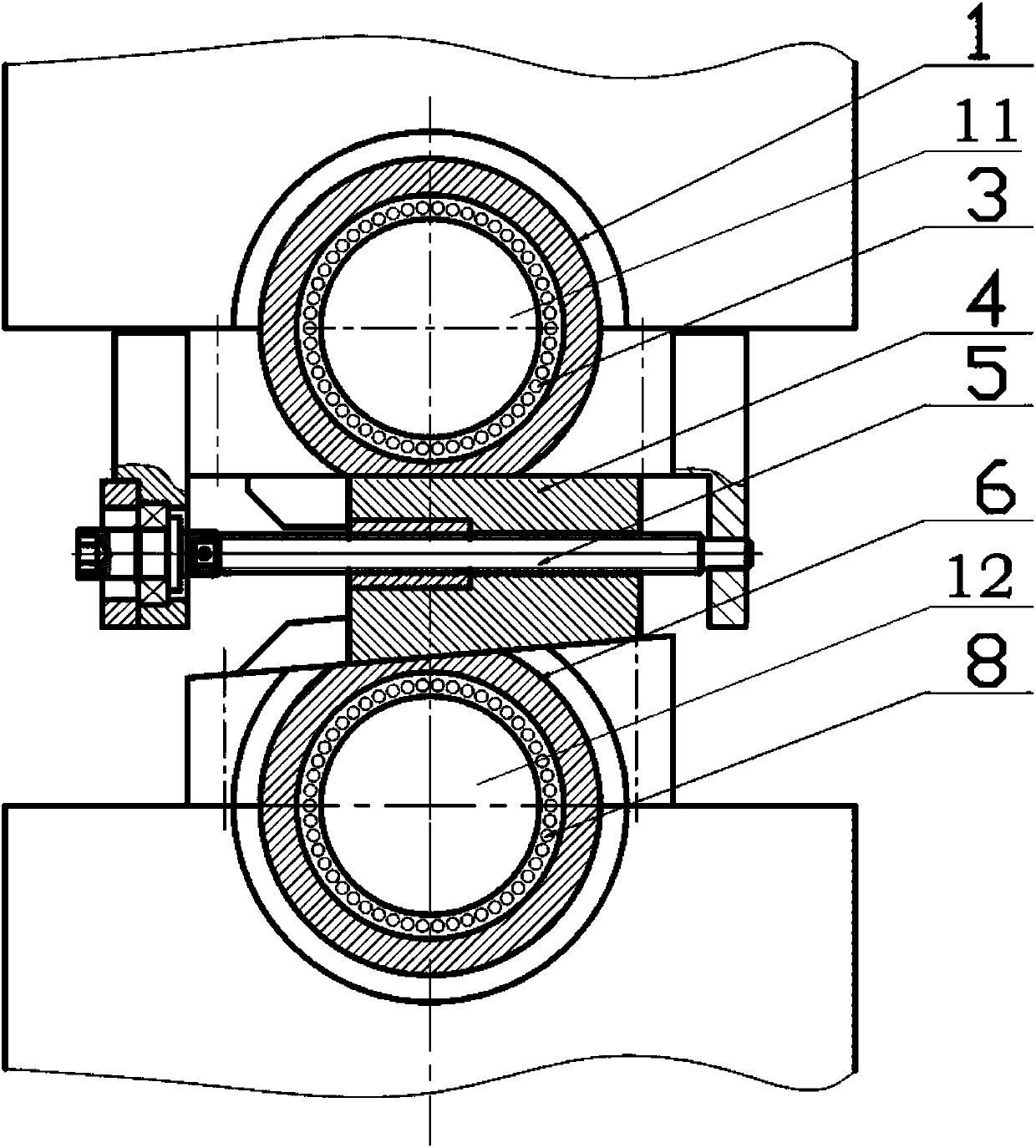

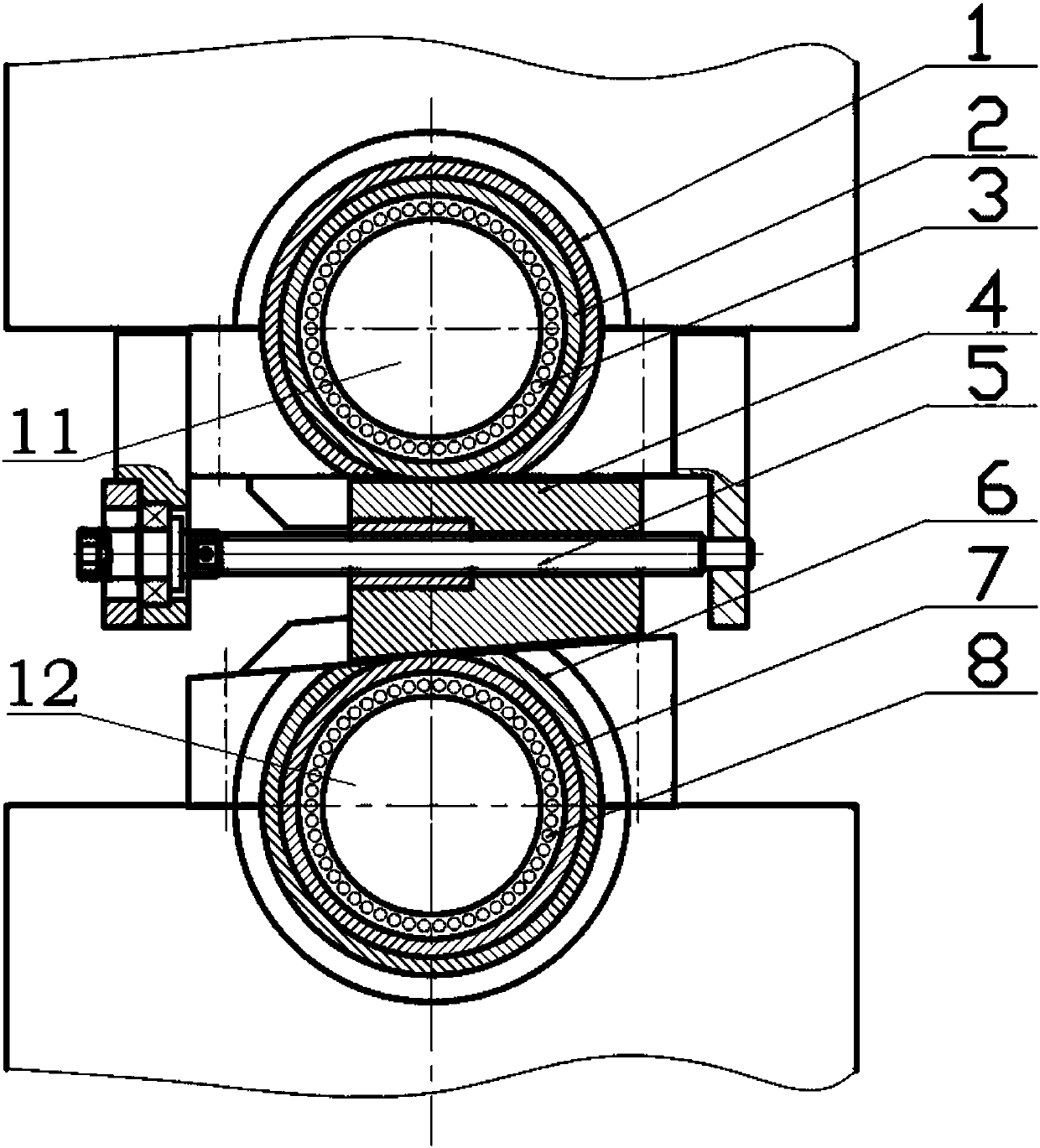

Belling bearing spacing adjustment device

PendingCN107718857AHigh precisionAccurate and reliable spacing adjustmentRotary pressesFixed bearingRotational axis

The invention discloses a belling bearing spacing adjustment device. The belling bearing spacing adjustment device comprises two bearing packs arranged in the up-down direction and an adjustment device body arranged between the two bearing packs. A rotary shaft is arranged between the two sets of bearing packs, rolling bearings are arranged on the outer portion of the rotary shaft, at least two rolling bearings are arranged in the axial direction of the rotary shaft, a rotary movable sleeve is arranged at the outer ring of one rolling bearing, fixed bearing sleeves are arranged at the outer rings of the other rolling bearings, and the fixed bearing sleeves are fixedly connected with a bearing seat; the adjustment device comprises a rotary lead screw and an oblique iron block, the oblique iron block is provided with an inclined face, and the inclined face is in contact with the outer ring of the rotary moving sleeve in at least one bearing pack; and the oblique iron block can be drivento move in the axial direction through the rotary lead screw, and further the corresponding bearing packs can move up and down through the rotary moving sleeves being in contact with the inclined face. According to the belling bearing spacing adjustment device, spacing adjustment between two belling bearings can be rapidly and stably achieved, meanwhile the precision of spacing adjustment is improved, and the product yield is increased.

Owner:CHANGDE JINPENG PRINTING

Friction Compensation Control Method of Motor Position Servo System Based on Multilayer Neural Network

ActiveCN107561935BSolve uncertain nonlinear problems such as nonlinear frictionImprove tracking accuracyAdaptive controlElectric machineControl engineering

The invention discloses a friction compensation control method for a motor position servo system based on a multilayer neural network, which belongs to the field of electromechanical servo control; The adaptive robust controller of the network observer compensates complex uncertain terms in nonlinear friction through a multi-layer neural network, and at the same time designs an adaptive robust controller to estimate uncertain parameters in the system, as well as compensate for external disturbances and neural The approximation error of the network. The control method designed by the invention can effectively solve the non-linear friction problem of the motor servo system, and can ensure the excellent tracking performance of the motor servo system.

Owner:NANJING UNIV OF SCI & TECH

A micro-force-measuring three-dimensional comprehensive thread measuring machine probe and its measuring method

The invention provides a measuring head of a three-dimensional comprehensive thread measuring machine with micro-force force measurement and a measuring method thereof, which can simply and accurately measure the displacement of the probe, thereby measuring the spatial position of the measured thread. The micro-displacement of the probe in the horizontal and vertical directions is respectively measured by the transverse micro-displacement system and the longitudinal micro-displacement system. The probe is pre-contacted with the thread to be measured. After the three-dimensional comprehensive thread measuring machine is driven, the probe is displaced in the horizontal and vertical directions respectively. Two sets of parallel reeds are used as the guiding mechanism and are respectively stretched. The relative displacement of the grating occurs, and the displacement is measured. The invention is used for thread detection by a three-dimensional comprehensive thread measuring machine of micro force measuring type.

Owner:CHOTEST TECH INC

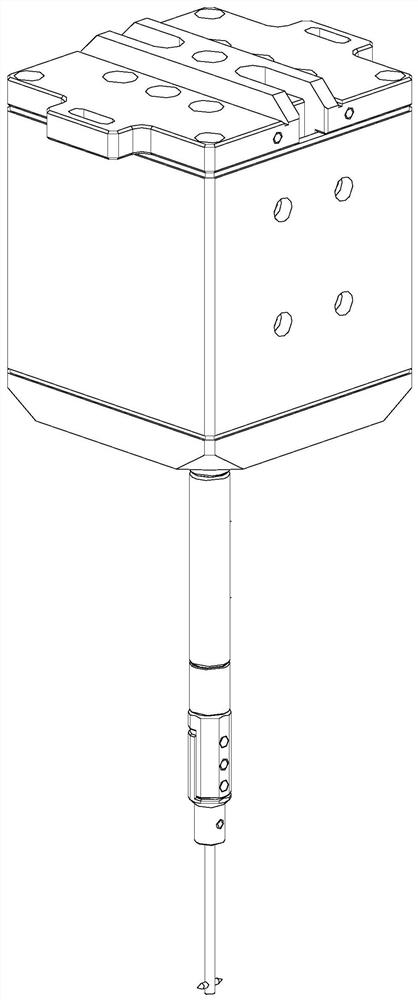

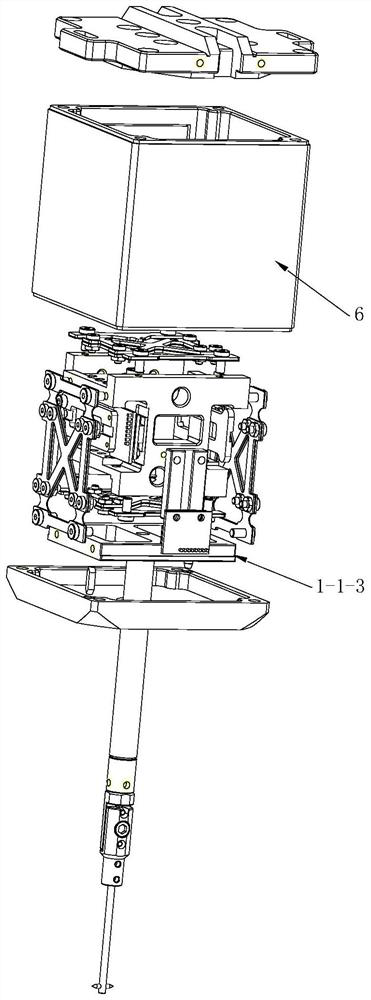

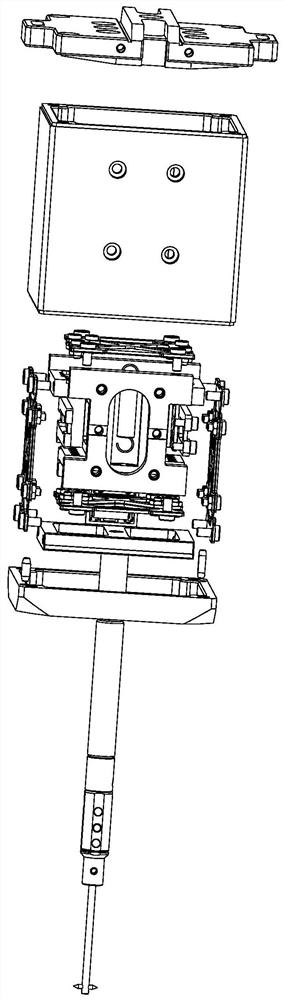

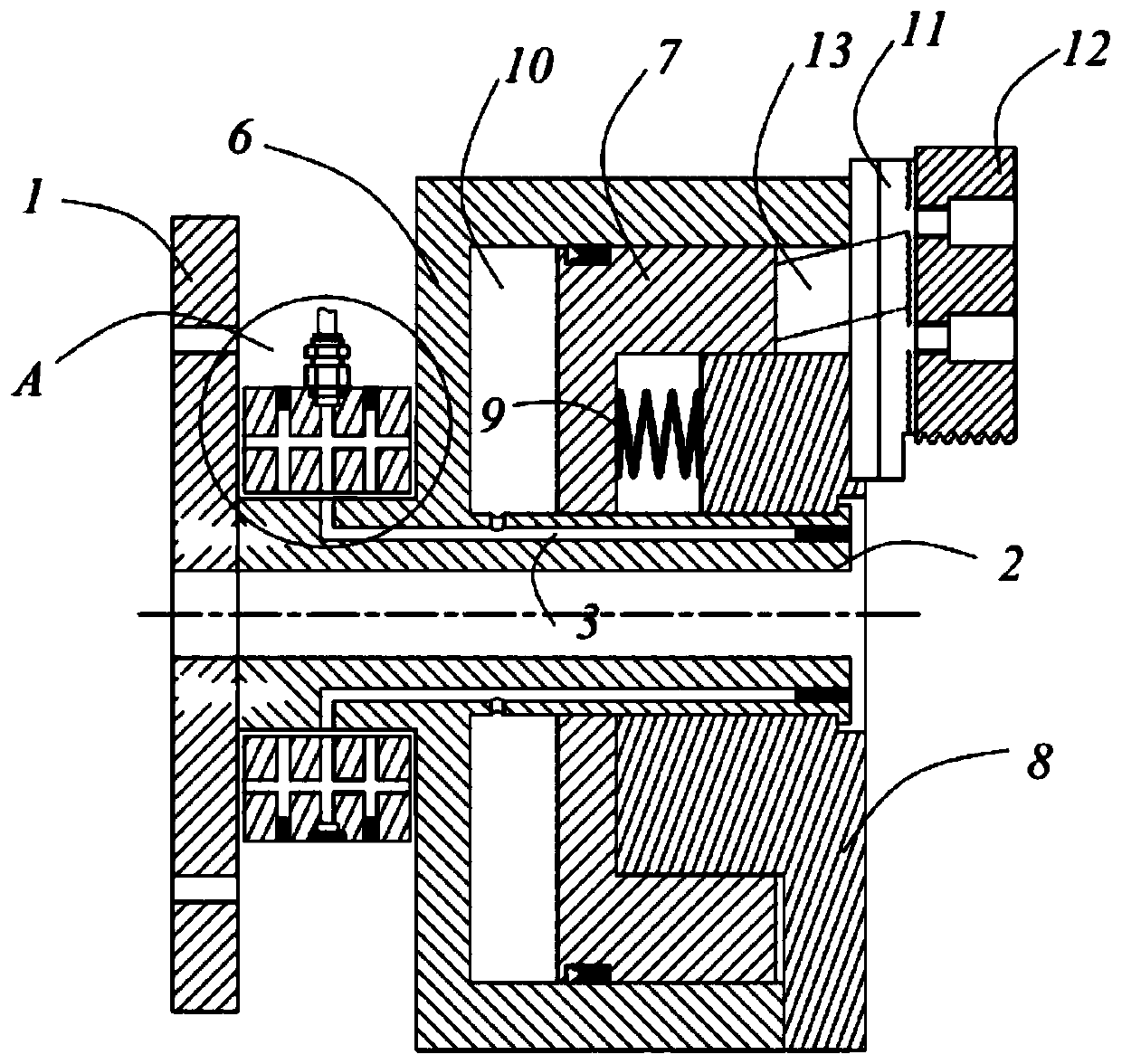

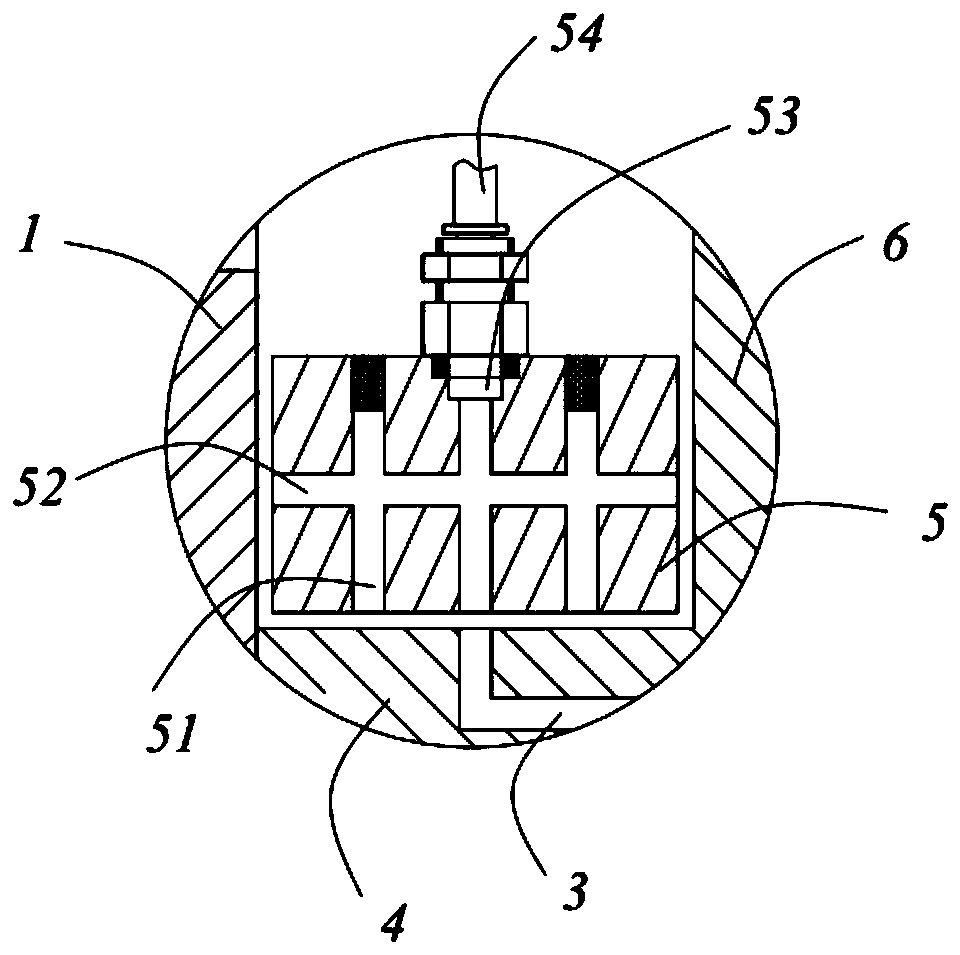

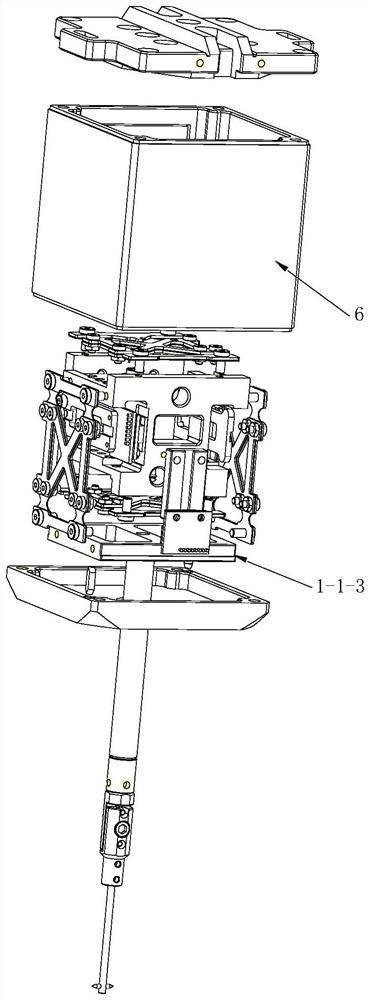

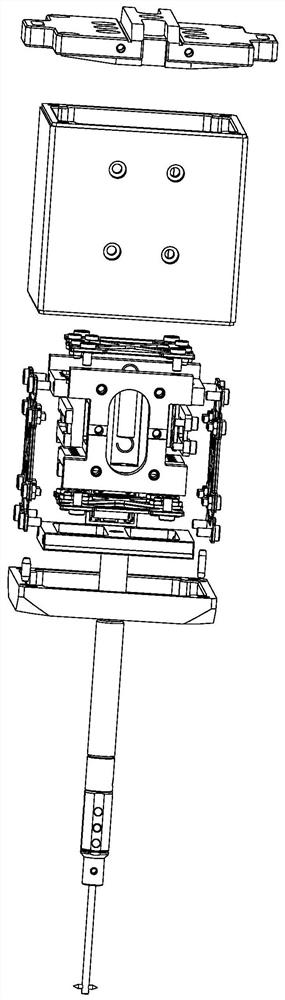

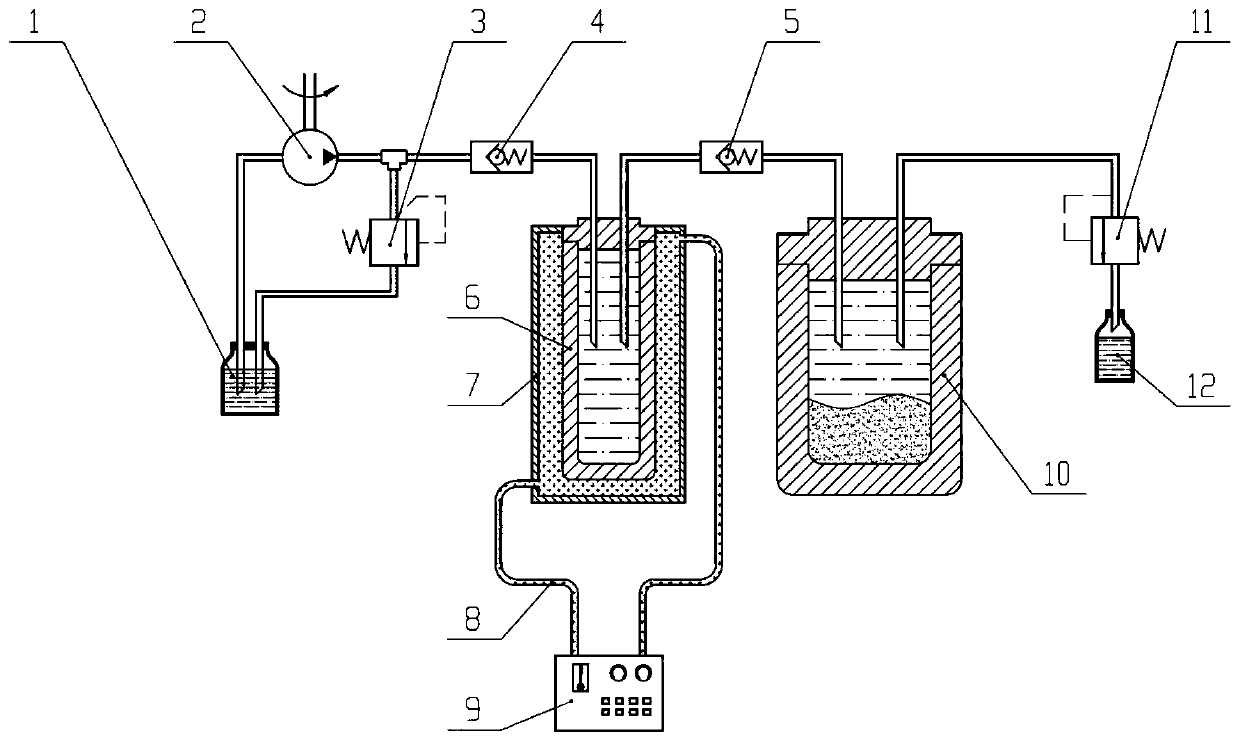

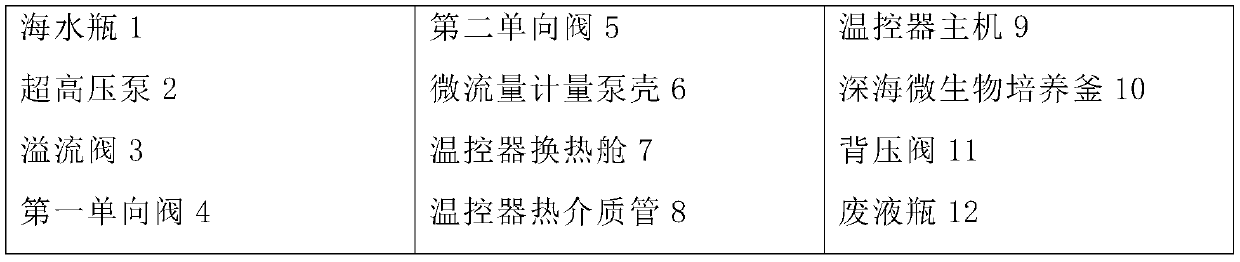

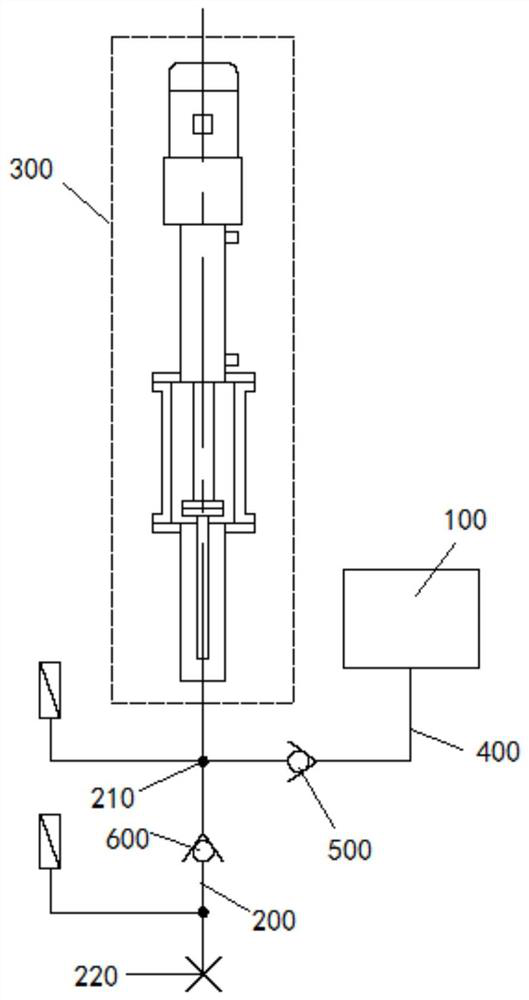

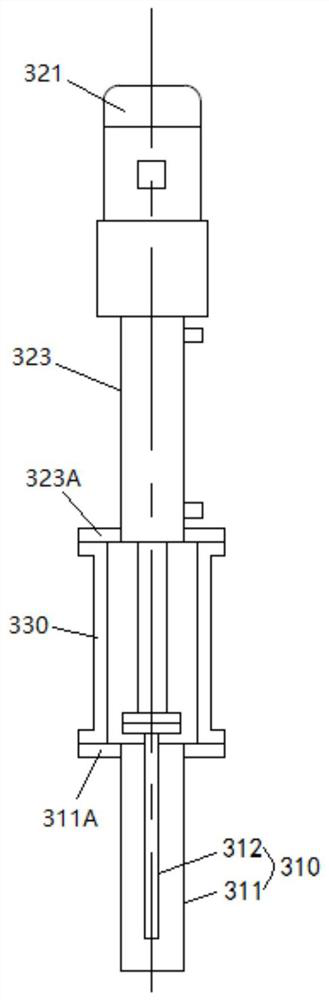

Metering pump

ActiveCN110905755AAchieve pumpingNo crawlingPump installationsPositive-displacement liquid enginesMicroorganismUltra high pressure

The invention provides a metering pump. The metering pump comprises a seawater bottle (1), an ultrahigh pressure pump (2), a micro-flow metering pump shell (6), a temperature controller heat exchangecabin (7), a temperature controller host (9), a deep sea microorganism culture kettle (10) and a waste liquid bottle (12). A water suction port of the ultrahigh pressure pump (2) is connected with anoutlet of the seawater bottle (1). A water outlet of the ultrahigh pressure pump (2) is connected with an inlet of the micro-flow metering pump shell (6). A temperature controller heat exchange cabin(7) is arranged on an outer side of the micro-flow metering pump shell (6). The temperature controller heat exchange cabin (7) is connected with the temperature controller host (9) through a pipeline.The outlet of the micro-flow metering pump shell (6) is connected with the inlet of the deep sea microorganism culture kettle (10) through the pipeline. The outlet of the deep sea microorganism culture kettle (10) is connected with the waste liquid bottle (12) through the pipeline. The micro-flow metering pump shell is pre-pressurized through a conventional high-pressure pump, and pumping efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

Turntable Transmission Device of CNC Spiral Bevel Gear Milling Machine

ActiveCN103586725BEasy to operatePrevent chatterFeeding apparatusGear-cutting machinesNumerical controlLow speed

Owner:通用技术集团天津第一机床有限公司

High-speed notching machine

ActiveCN103949526APrecise displacement controlFor precise cuttingMetal-working feeding devicesPositioning devicesDisplacement controlEngineering

The invention provides a high-speed notching machine and relates to the field of machining equipment. The high-speed notching machine comprises a machine body, a motor, an indexing box, a swinging block mechanism and a driving mechanism, wherein the motor, the indexing box, the swinging block mechanism and the driving mechanism are arranged on the machine body; the motor is connected with the swinging block mechanism; the indexing box comprises an indexing spindle and an indexing box body; the indexing spindle is horizontally and slidably arranged on the indexing box body; the indexing box body is horizontally and slidably arranged on a guide rail arm extending out of the machine body; the indexing box body is connected with the guide rail arm through at least one rolling guide rail pair; a screw rod is further arranged between the indexing box body and the guide rail arm; one end of the screw rod is connected with the indexing box body, and the other end of the screw rod penetrates through the guide rail arm and is connected with the driving mechanism. According to the high-speed notching machine provided by the invention, the indexing box is connected with the machine body by using a rolling sliding pair; the friction force of the rolling sliding pair is stable and easy to control, so that displacement of the indexing box on the machine body can be accurately controlled, and a sample can be more accurately cut and can be more conveniently controlled.

Owner:芜湖天鹏数控高速冲槽机制造有限公司

Adjusting device

Owner:NEW FOUNDER HLDG DEV LLC +2

Full CNC spiral bevel gear milling machine

ActiveCN103567550BStable and reliable transmissionMove fastDriving apparatusGear-cutting machinesNumerical controlGear wheel

The invention relates to a full-numerical-control spiral bevel gear milling machine. The full-numerical-control spiral bevel gear milling machine comprises a lathe bed, a stand column, a tool box, a workpiece box, a rotary table transmission device, an electric system, a pneumatic system, a hydraulic system and a cooling system. The full-numerical-control spiral bevel gear milling machine is characterized in that a machine tool spindle torque motor rotor is connected with a machine tool spindle, the machine tool spindle is provided with a spindle damping mechanism, one end of a workpiece spindle is directly fastened with the machine tool spindle torque motor rotor, a workpiece spindle clamping mechanism is arranged at the other end of in a box body of the workpiece box, the workpiece spindle is provided with a workpiece spindle damping mechanism, and the rotary table transmission device comprises a worm wheel bottom sleeve, a worm wheel and worm pair, a rotary table oscillating bar mechanism, a rotary table clamping oil cylinder and a supporting base. The full-numerical-control spiral bevel gear milling machine has the advantages that a torque motor is adopted to serve as power to directly drive the machine tool spindle and the workpiece spindle, the transmission precision and the machining efficiency can be improved greatly, adjustment is convenient, and the rigidity is good; due to driving of the worm wheel and worm pair, the adjustment on the root angle of the workpiece box and the large rotation of feeding and discharging are achieved, and the rotary table oscillating bar mechanism achieves the finish machining of a small gear wheel matched with a forming-method big gear wheel and the machining of a cycloid gear.

Owner:通用技术集团天津第一机床有限公司

Air-actuated muscle motion analog control platform device and posture control method

InactiveCN100464355CGreat effortReduce volumeCosmonautic condition simulationsAmusementsControl systemComputer module

Owner:ZHEJIANG UNIV

Liquid supply equipment, control method of liquid supply equipment, hydraulic system and safety valve detection system

PendingCN112145390AGood speed transfer performanceGood speed regulation performancePositive displacement pump componentsEqualizing valvesReciprocating motionEngineering

The invention discloses liquid supply equipment, a control method of the liquid supply equipment, a hydraulic system and a safety valve detection system. High-pressure liquid with constant flow can beoutput. The liquid supply equipment comprises a liquid tank, a liquid supply pipeline, a loading device, a first valve and a second valve, wherein a liquid inlet and a liquid supply port are arrangedon the liquid supply pipeline the loading device comprises a plunger cylinder and a driving device, the plunger cylinder comprises a plunger cylinder barrel and a piston in sliding fit with a workingcavity of the plunger cylinder barrel, a first piston rod is connected to the piston, the liquid tank communicates with a working cavity of the plunger cylinder barrel through a liquid inlet pipeline, a liquid inlet of the liquid supply pipeline communicates with the working cavity of the plunger cylinder barrel, the driving device comprises a motor and a transmission assembly, the transmission assembly can convert rotation of the motor into reciprocating motion of the first piston rod, transmission parts in the transmission assembly are made of rigid materials, the first valve is connected to the liquid inlet pipeline in series, and the second valve is connected to the liquid supply pipeline in series.

Owner:CCTEG CHINA COAL RES INST

High-speed notching machine

ActiveCN103949526BPrecise displacement controlFor precise cuttingMetal-working feeding devicesPositioning devicesDisplacement controlRolling sliding

The invention provides a high-speed notching machine and relates to the field of machining equipment. The high-speed notching machine comprises a machine body, a motor, an indexing box, a swinging block mechanism and a driving mechanism, wherein the motor, the indexing box, the swinging block mechanism and the driving mechanism are arranged on the machine body; the motor is connected with the swinging block mechanism; the indexing box comprises an indexing spindle and an indexing box body; the indexing spindle is horizontally and slidably arranged on the indexing box body; the indexing box body is horizontally and slidably arranged on a guide rail arm extending out of the machine body; the indexing box body is connected with the guide rail arm through at least one rolling guide rail pair; a screw rod is further arranged between the indexing box body and the guide rail arm; one end of the screw rod is connected with the indexing box body, and the other end of the screw rod penetrates through the guide rail arm and is connected with the driving mechanism. According to the high-speed notching machine provided by the invention, the indexing box is connected with the machine body by using a rolling sliding pair; the friction force of the rolling sliding pair is stable and easy to control, so that displacement of the indexing box on the machine body can be accurately controlled, and a sample can be more accurately cut and can be more conveniently controlled.

Owner:芜湖天鹏数控高速冲槽机制造有限公司

Azimuth rotating static pressure support system for tower solar thermal power generation heliostats

ActiveCN106949106BSmall turning torqueLow costServomotor componentsServomotorsHydraulic motorSupporting system

The invention relates to an azimuth rotation static-pressure support system of a tower solar thermal power generation heliostat. The tower solar thermal power generation heliostat includes a tower frame, a hydraulic motor speed reducer, an azimuth rotating unit and a pitching motion unit. The system designs chute and slide ring structures, and injects oil to the lower bottom end surface of a slide ring and the upper flat end surface of a chute through a pressure reducing valve, a one-way valve and a capillary throttling valve, so that the lubricating performance is greatly improved, the rotating torque of the tower heliostat azimuth is reduced by 70% compared with the torque of a mechanical drive, the azimuth rotation driving torque is largely reduced, the sizes of the driving device and the hydraulic motor are both largely reduced, and the cost of the azimuth driving device is correspondingly reduced.

Owner:TIANJIN OULU HEAVY MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com