High-speed notching machine

A high-speed punching and slotting machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems affecting product accuracy, large errors, waste of production resources, etc., and achieve easy control, convenient control, and accurate cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

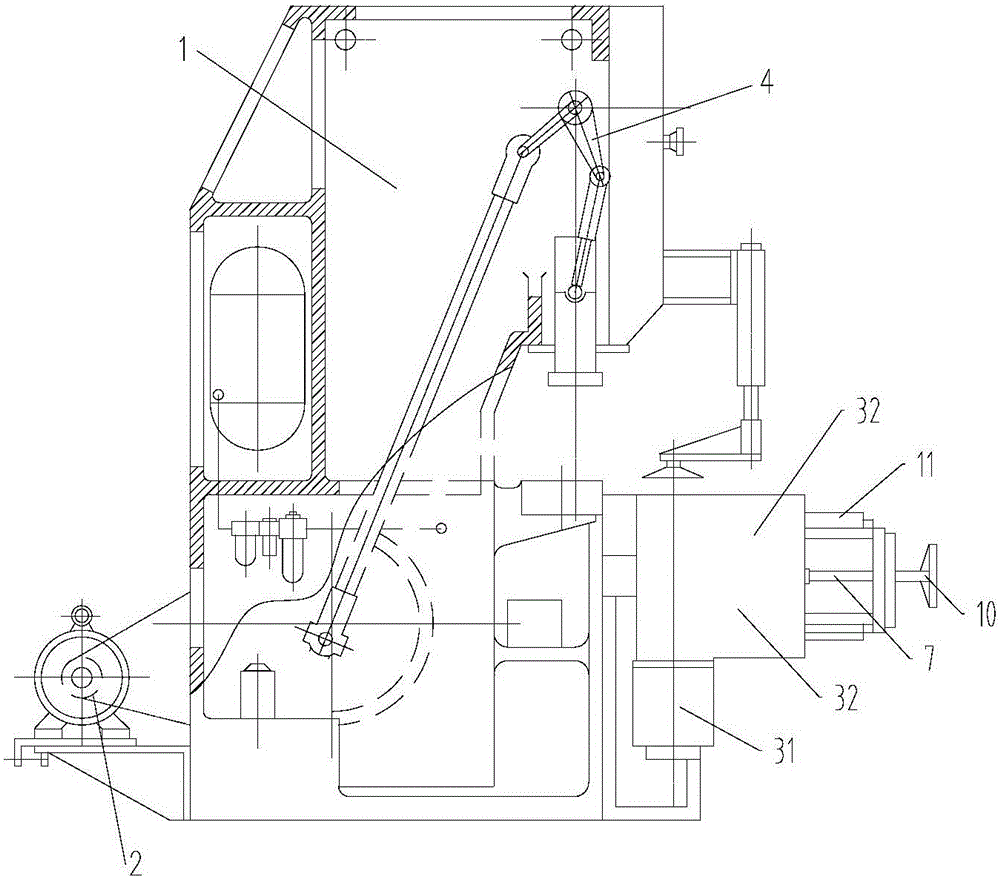

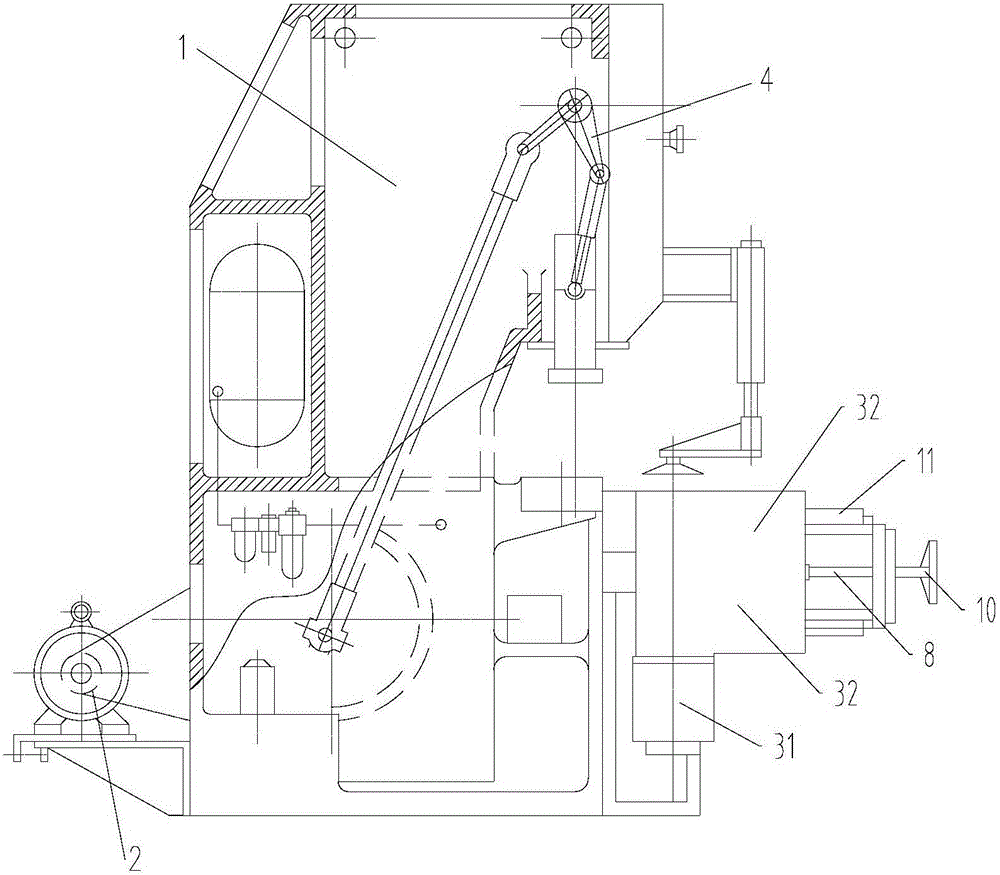

[0023] The high-speed notching machine provided by the first embodiment of the present invention includes a main body 1, a motor 2, an indexing box, a pendulum mechanism 4 and a driving mechanism;

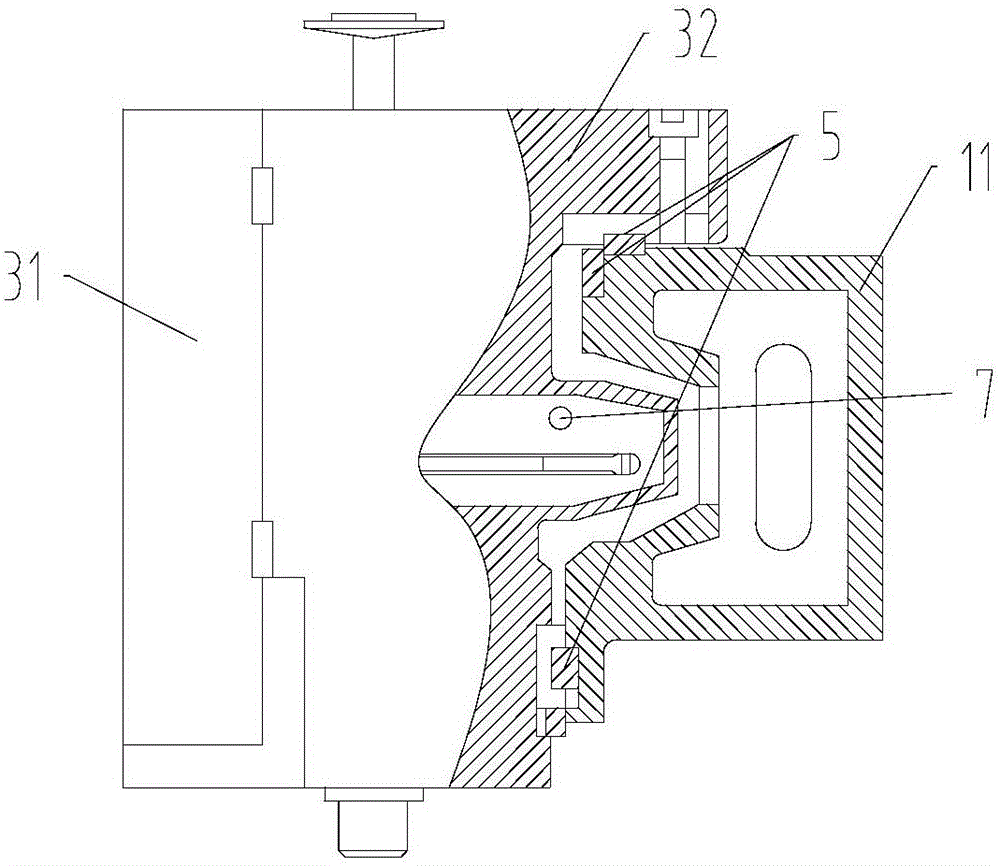

[0024] Motor 2, indexing box, pendulum block mechanism 4 and driving mechanism are all installed on the fuselage 1, and motor 2 is connected with pendulum block mechanism 4; The horizontal sliding is arranged on the indexing box 32; the indexing box 32 is horizontally slidably arranged on the rail arm 11 protruding from the fuselage 1; the indexing box 32 is wrapped on the side of the rail arm 11, and the indexing box 32 It is connected with the guide rail arm 11 through at least one rolling guide rail pair 5, and the rolling guide rail pair 5 is arranged along the moving direction of the indexing box body 32, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com