Liquid supply equipment, control method of liquid supply equipment, hydraulic system and safety valve detection system

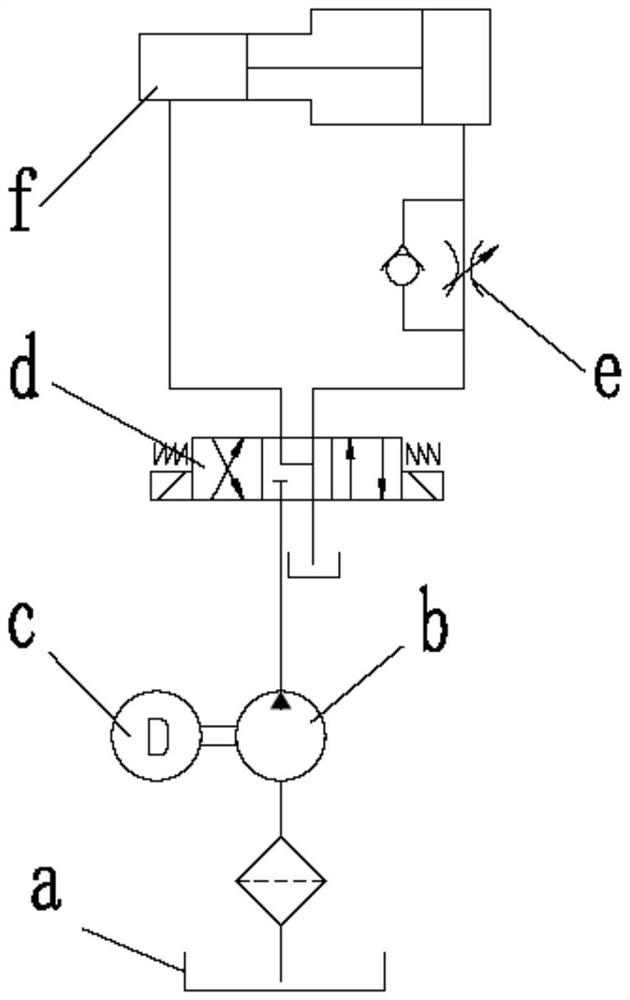

A safety valve and liquid supply technology, applied in the hydraulic field, can solve problems such as output flow fluctuation, poor micro-flow stability, and low applicable pressure, and achieve the effects of high speed regulation performance, high speed rigidity, and good speed transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

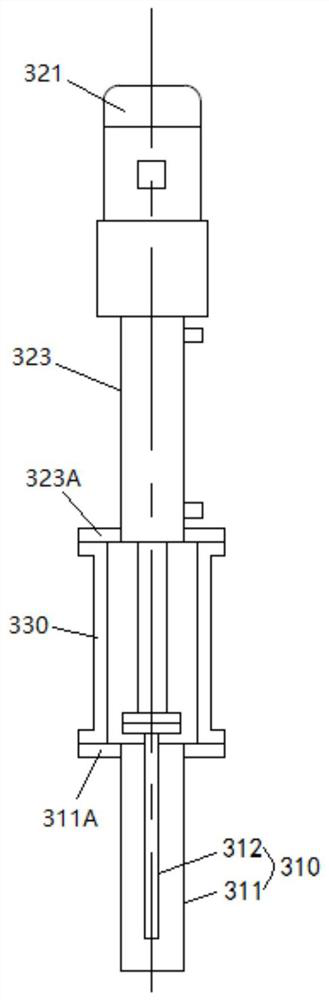

[0070] The present invention provides a liquid supply method for the above liquid supply equipment. see Figure 6 and Figure 7 , the above liquid supply methods include:

[0071] S100: Preliminary step: make the first group of loading devices 300 perform a liquid suction operation. At this time, the working fluid is stored in the working chamber of the plunger cylinder 311 in the first group of loading devices 300 .

[0072] Wherein, the liquid suction operation includes: controlling the motor 321 to rotate in a first direction, so as to move the first piston rod 312 from the first position to the second position. Wherein, when the first piston rod is at the first position, the first end of the first piston rod is flush with the bottom of the working chamber of the plunger cylinder. When the first piston rod is at the second position, the first piston rod is flush with the top of the working chamber of the plunger cylinder.

[0073] S200: first liquid supply step: make the...

Embodiment approach 3

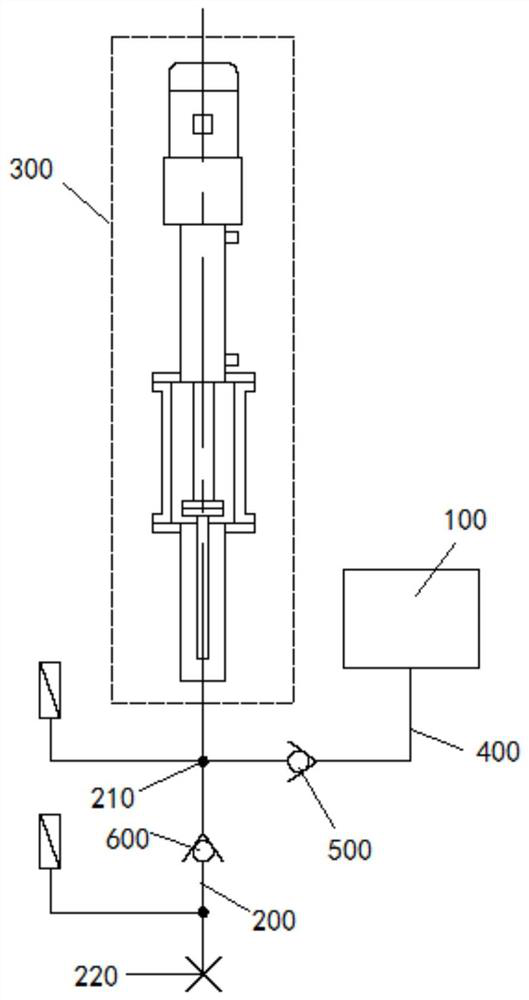

[0090] Embodiment 2 of the present invention provides a hydraulic system. see figure 2 and Figure 10 , the hydraulic system includes the above-mentioned liquid supply device A and the execution device B, and the liquid supply port 220 of the liquid supply device A communicates with the liquid inlet port of the execution device B.

[0091] At this time, the high-pressure liquid provided by the liquid supply device A can drive the actuator B to perform linear motion and reciprocating motion.

[0092] It should be noted that the structure of the above-mentioned actuator B can be selected according to the actual situation, as long as the actuator B can convert the pressure of the high-pressure liquid into the power of linear motion or reciprocating motion.

[0093] For example, the aforementioned executing device B may be a hydraulic cylinder.

[0094] Compared with the prior art, the beneficial effects of the hydraulic system provided by the embodiment of the present inventi...

Embodiment approach 4

[0096] The opening pressure of the safety valve for the hydraulic support will affect the support performance of the hydraulic support, and then affect the stability of the surrounding rock of the working face. If the opening pressure of the safety valve is too low, the working resistance of the column and the supporting jack will be insufficient, resulting in the appearance of mine pressure on the working face. If the opening pressure is too high, the column and the jack will be damaged due to the excessive working resistance and the inability to overflow and release the pressure in time.

[0097] According to the requirements of national standards, before the safety valve leaves the factory, the opening, overflow and closing characteristics of the safety valve must be randomly checked. However, during the detection process of the safety valve, under different detection flow rates and detection pressures, the measured opening pressure, overflow maximum value, overflow minimum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com