Thermal treatment furnace

A technology for heat treatment furnaces and furnace shells, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of unavailable heat treatment equipment, high labor intensity, and easy burnout of crawler heaters, etc., to improve heat treatment efficiency, The effect of solving cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the present invention will be specifically described through exemplary embodiments. It is to be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

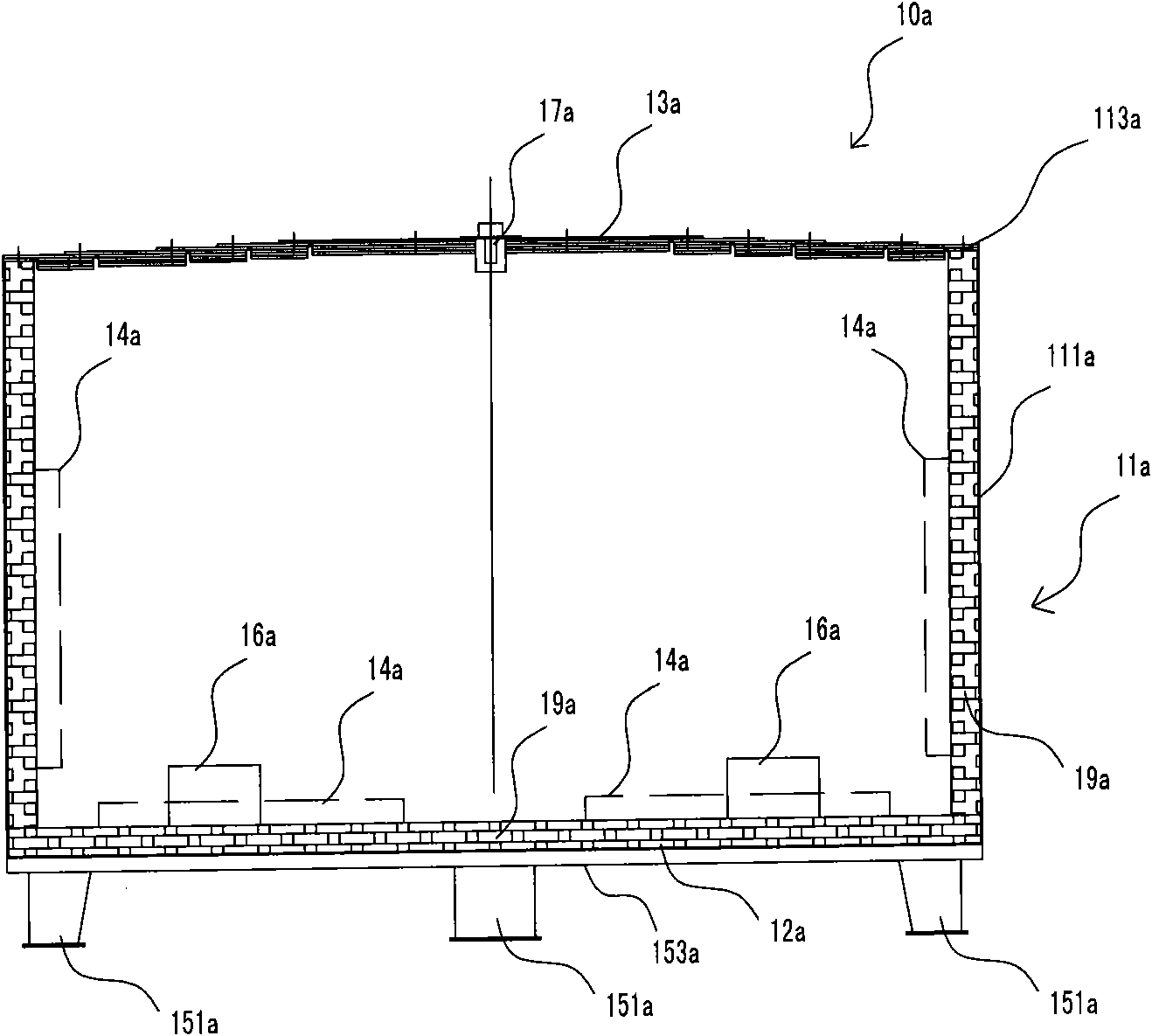

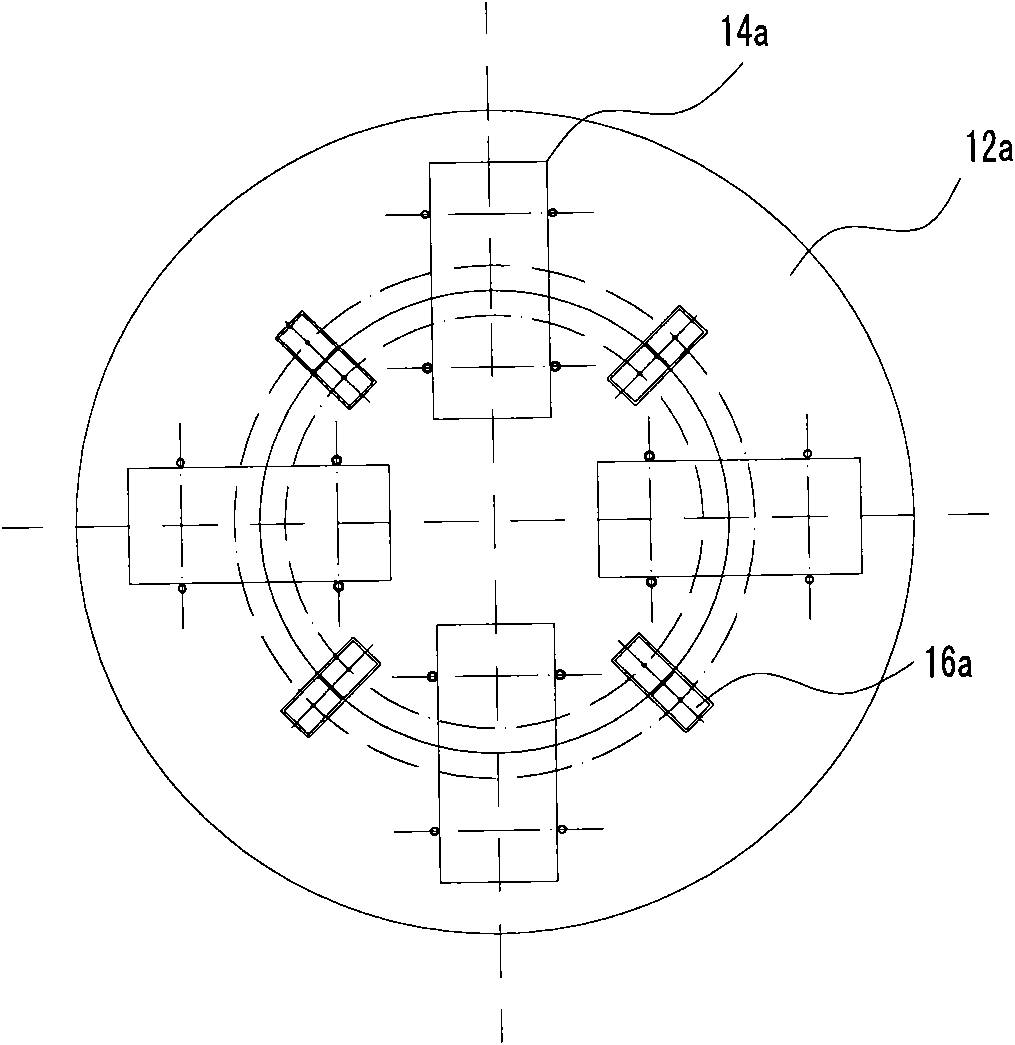

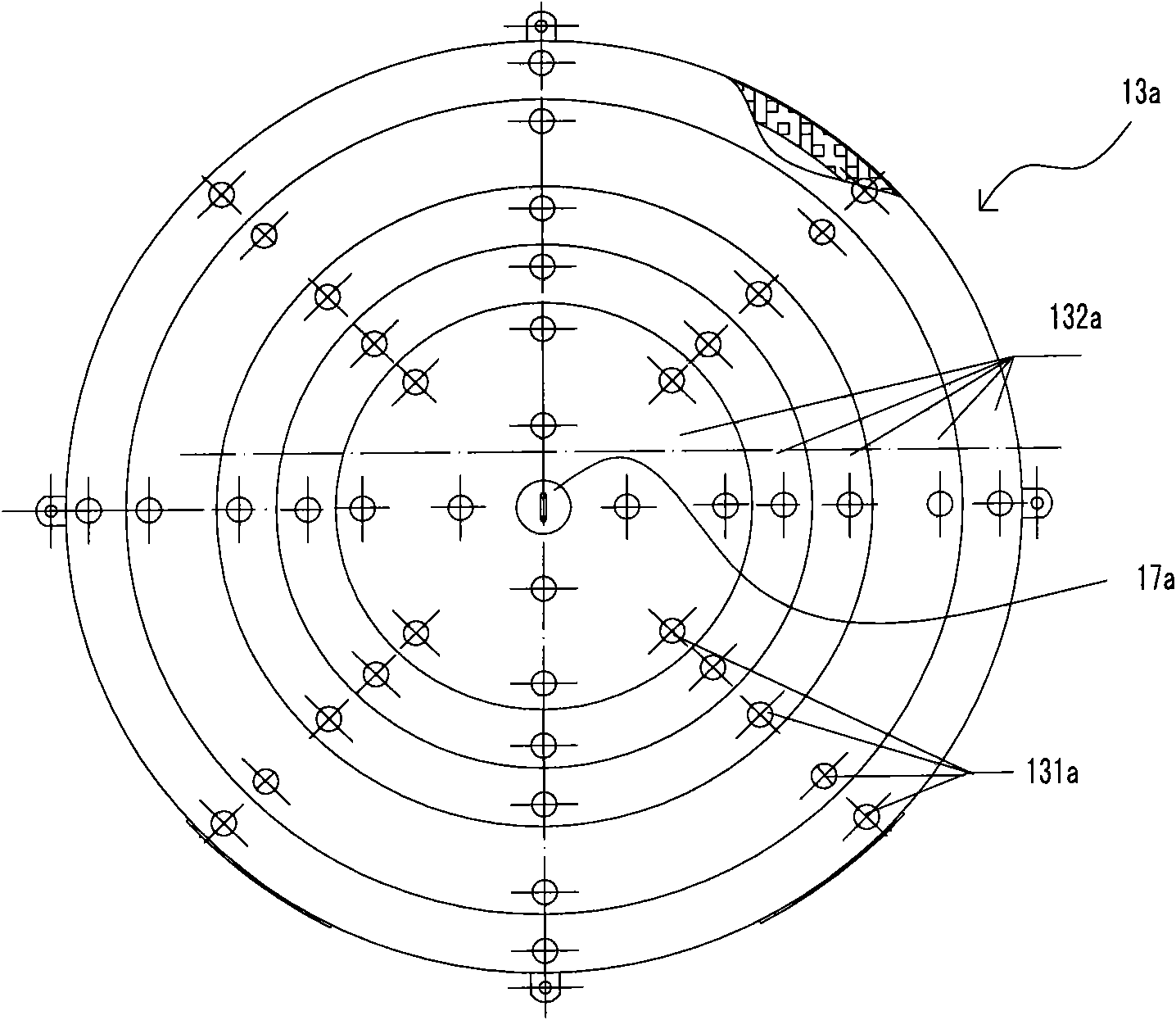

[0034] figure 1 Shown is a heat treatment furnace 10a according to an embodiment of the present invention, comprising an outer shell 11a, a bottom plate 12a, a furnace cover 13a and at least one heater 14a. Wherein, the bottom plate 12a is arranged at the bottom of the casing 11a, and the furnace cover 13a is arranged at the top of the casing 11a. In order to heat the workpiece to be processed, preferably, there are multiple heaters 14a installed on the inner wall of the casing 11a and / or the bottom plate 12a respectively. In order to play the role of fixed support, the heat treatment furnace 10a of the present invention also includes at least one fixed furnace base 151a and at least one mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com