Air film hole based on secondary flows of bent passage

A technology of curved channels and air film holes, applied in the field of air film holes, can solve the problem of no secondary flow utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

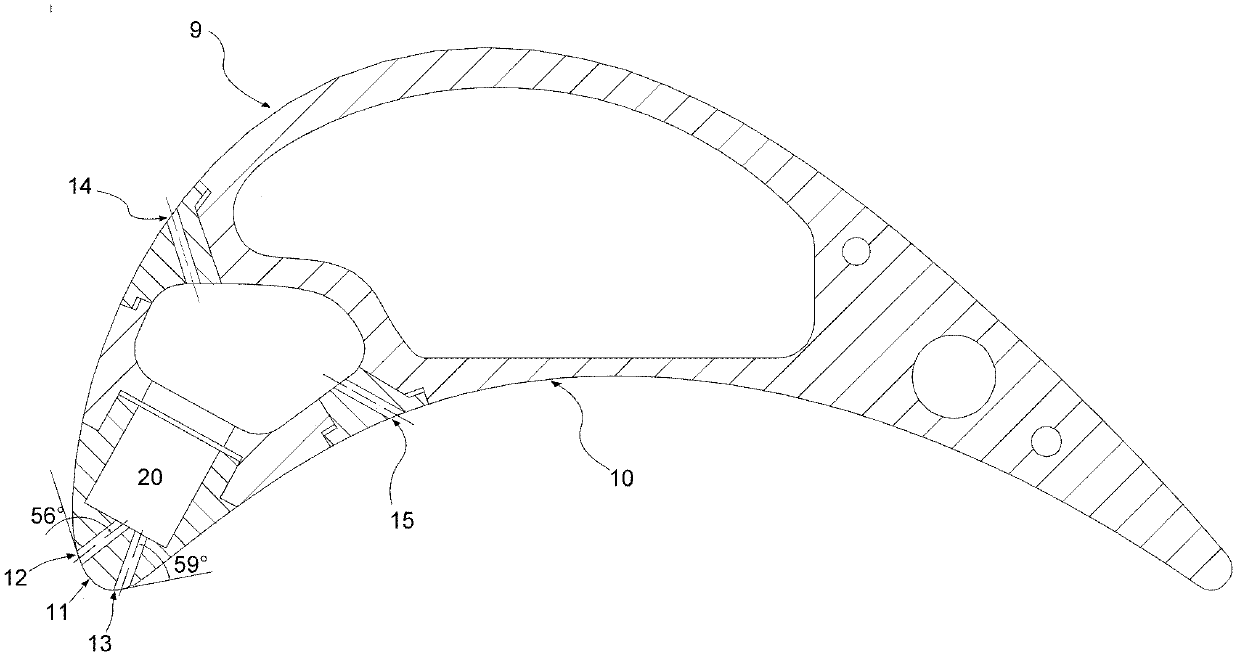

[0017] The present invention proposes a film hole based on the secondary flow of the curved channel, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The air film holes in the embodiment have no spanwise compound angle, but the blade type, installation position and angle applicable to the present invention are not limited by this example. The curved hole in this example can be obtained by placing the component in a magnetic field and processing it with an electron beam.

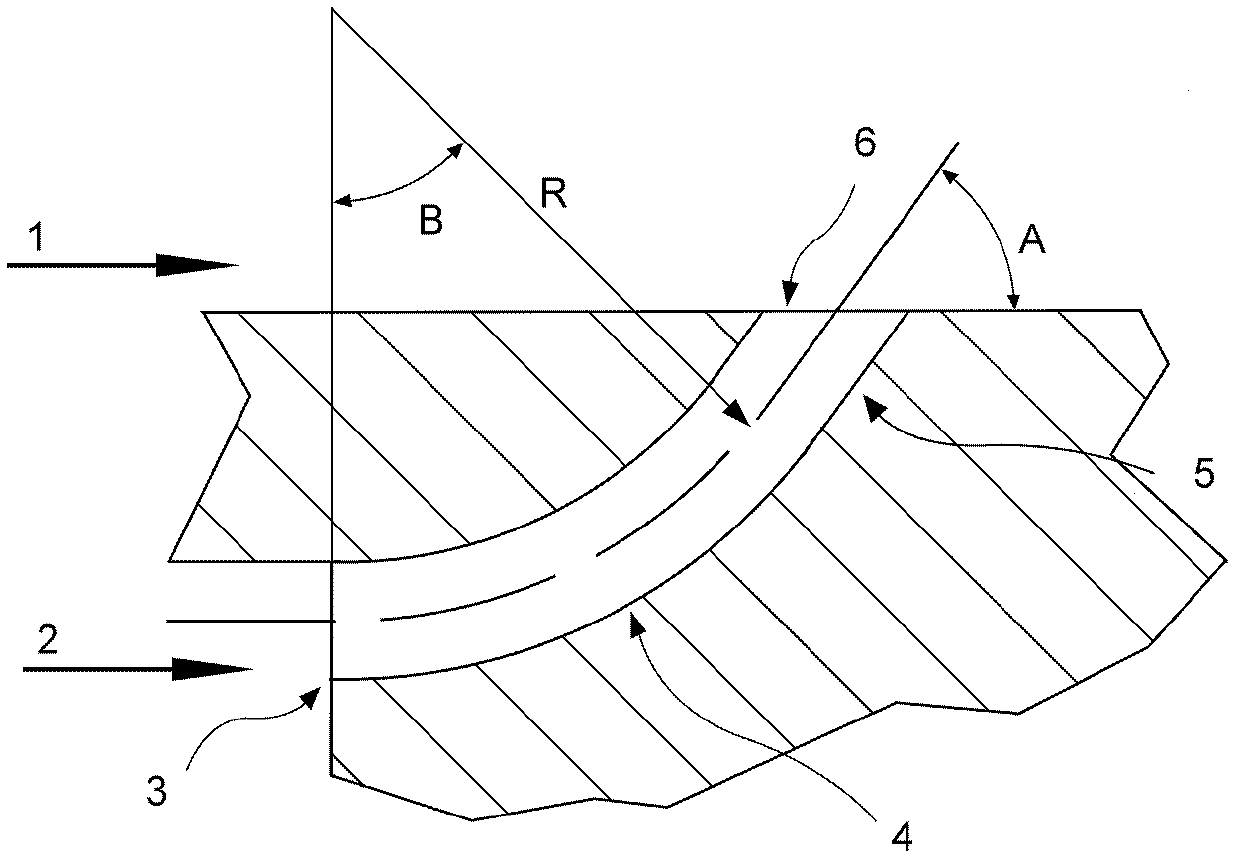

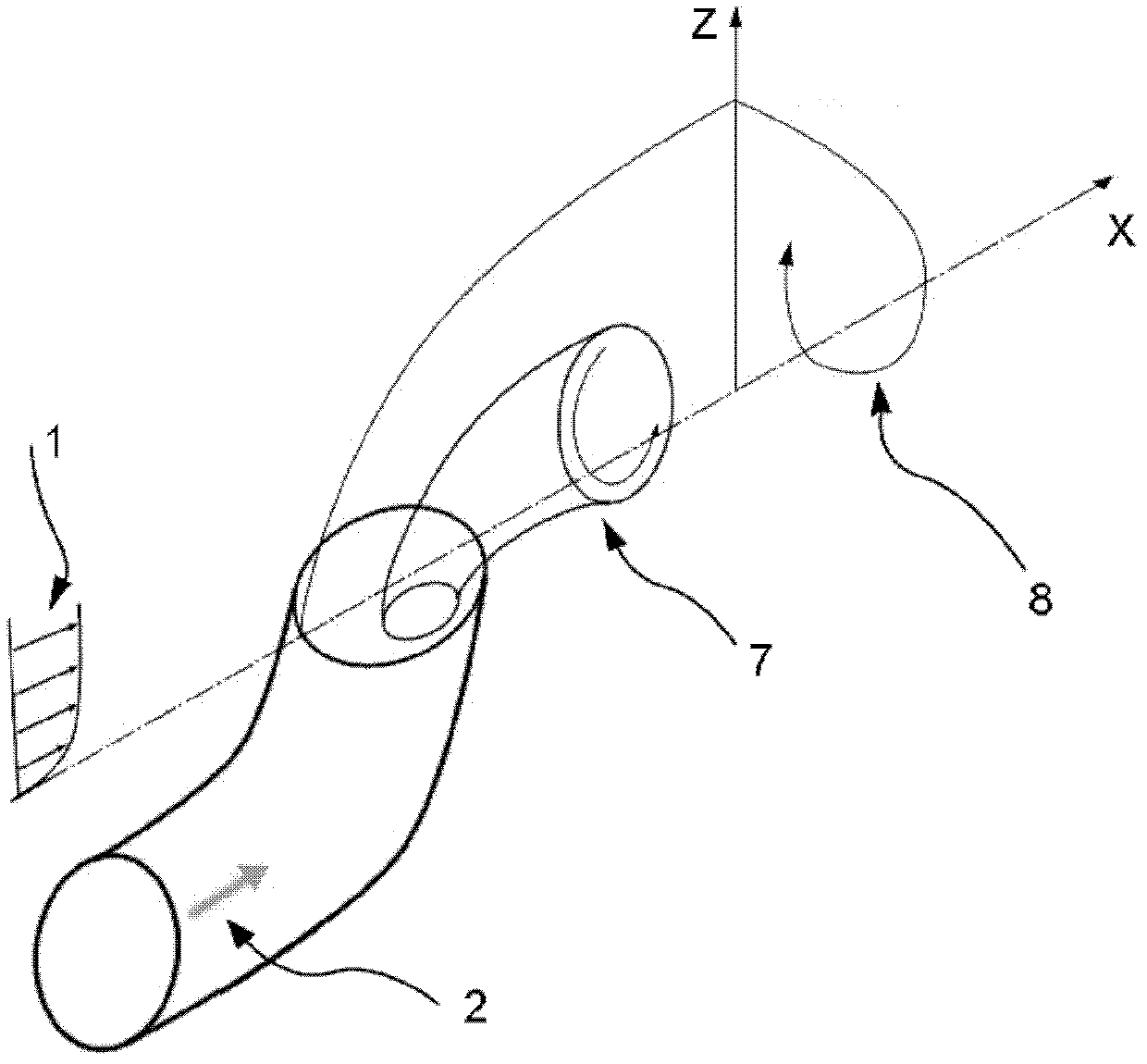

[0018] Such as figure 1 As shown, a number of air film holes are set on the air film, and the air film hole includes two parts: a curved channel section 4 and a straight channel section 5; The direction of the incoming flow of the high-temperature airflow is bent, the central angle B of the curved channel section 4 ranges from 10° to 60°, and the radius of curvature R of the axis of the curved channel section 4 is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com